LNG gas ventilation mast for ro-ro passenger ship

A technology of ro-passenger ships and gas, which is applied in the field of ro-passenger ships to achieve the effect of compact structure, taking into account both functionality and aesthetics, and improving the aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

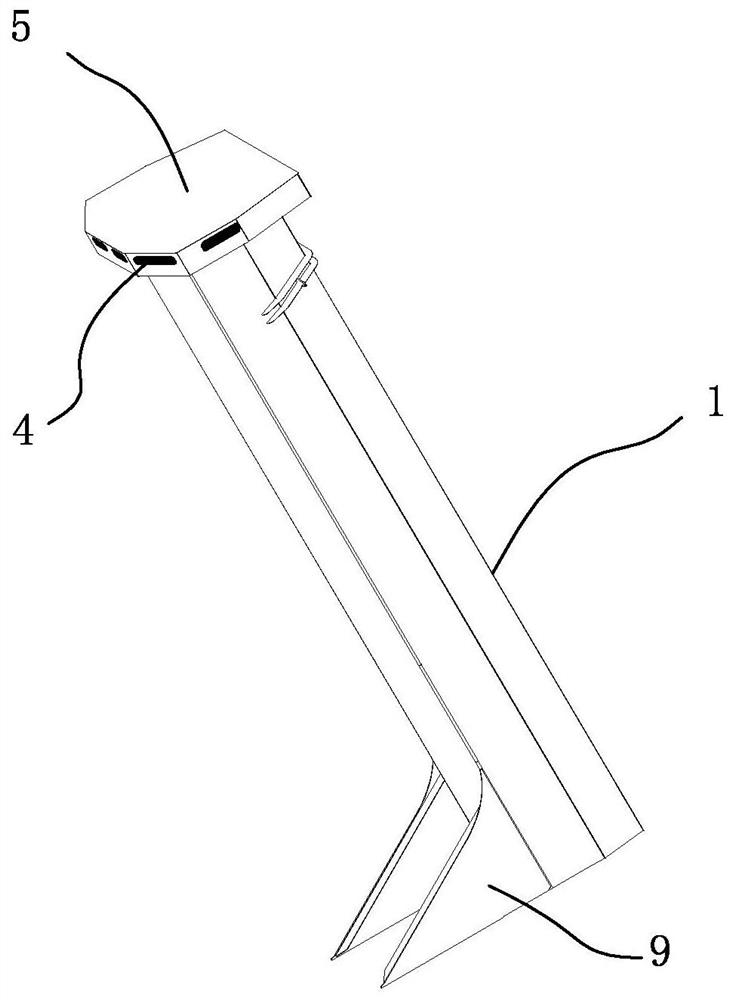

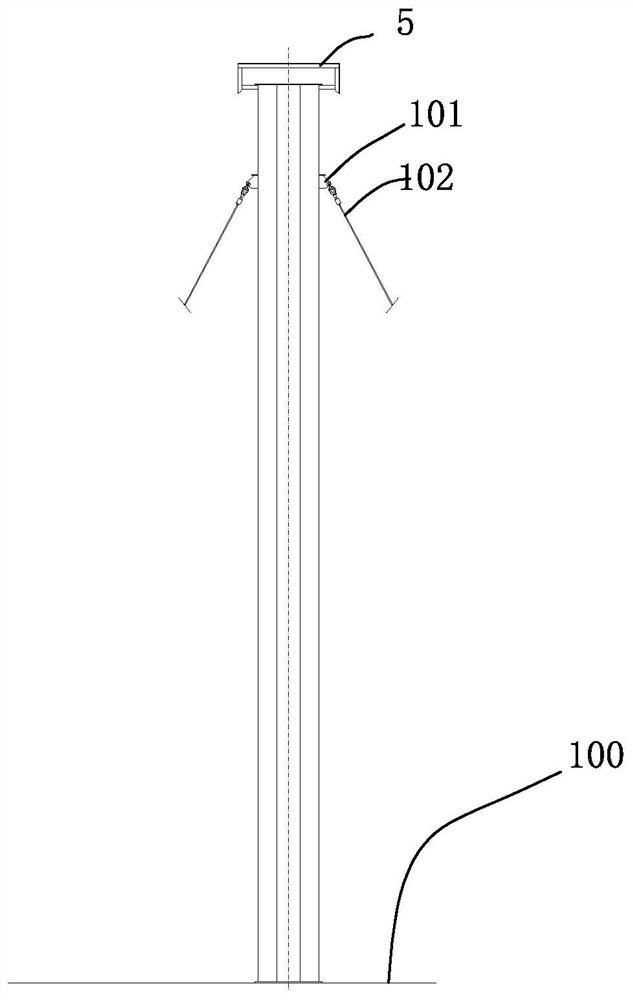

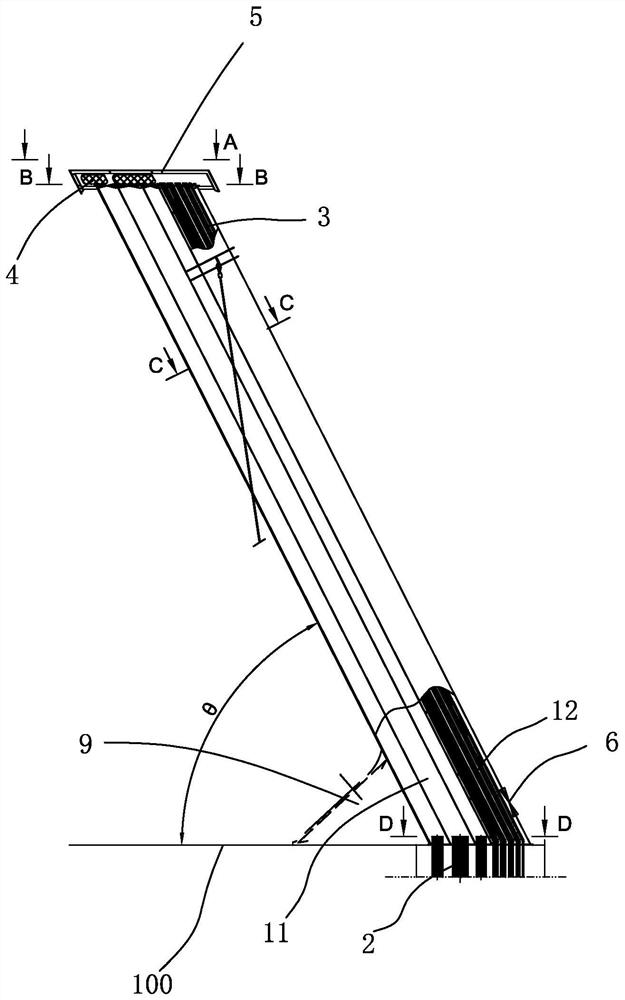

[0026] like Figure 1-7 As shown, a LNG gas ventilation mast for a ro-ro passenger ship may include a cylinder body 1, a first ventilation pipe 2, a second ventilation pipe 3, and the like. The cylinder body 1 is fixed on the weather deck 100 and has a certain height, so that the dangerous area is in a safe position. The cylinder body 1 is in an inclined design (inclined to the stern) as a whole, so that the ro-ro passenger ship is overall coordinated and beautiful. The inclination angle θ of the barrel 1 is generally not less than 60 degrees. The cylinder body 1 has a first channel 11 and a second channel 12 spaced apart from each other and extending along the length direction. The first channel 11 and the second channel 12 are arranged front and rear, that is, the first channel 11 is on the stern side, and the second channel 11 is on the bow side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap