Resin casting dry-type distribution transformer and preparation method thereof

A distribution transformer, resin casting technology, applied in the direction of transformer/inductor cooling, transformer/inductor parts, transformer/inductor coil/winding/connection, etc., can solve the problem of poor heat dissipation, slow speed, dry distribution To solve problems such as unstable operation of electric transformers, to achieve good heat dissipation effect, avoid delamination, and good fixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0033] Example 1:

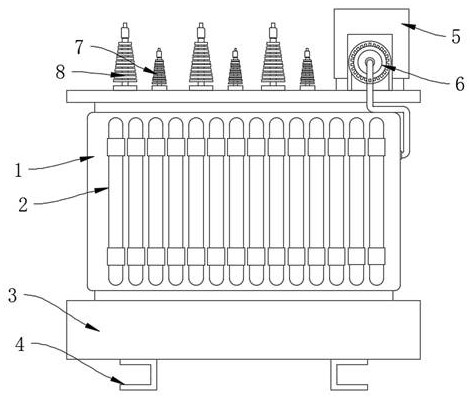

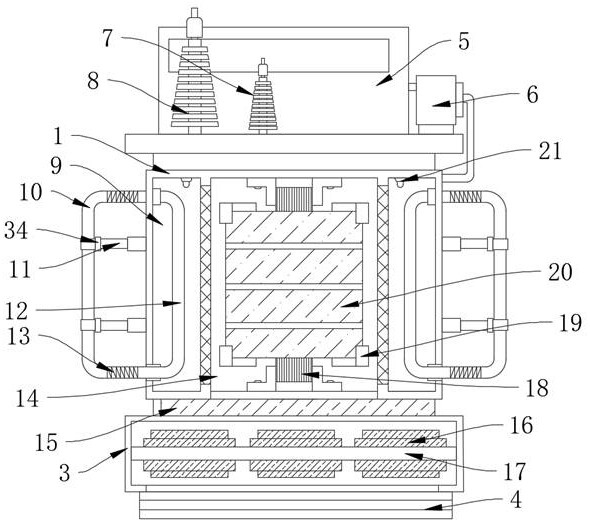

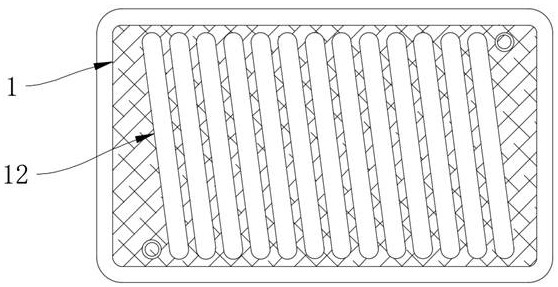

[0034] like Figure 1-7 As shown, the present invention provides a technical solution: a resin cast dry-type distribution transformer, including a box body 1, a cooling chamber 9 and a working chamber 14 are provided in the box body 1, and two sets of cooling chambers 9 are provided, and the cooling The cavity 9 is arranged on both sides of the working cavity 14, and the box body 1 is provided with an external heat dissipation structure 2 at the position of the cooling cavity 9, and the bottom end of the box body 1 is provided with a bottom cooling box body 3, and the bottom end of the bottom cooling box body 3 Two sets of mounting bases 4 are installed, an iron core 18 is arranged in the working chamber 14, and a coil group 20 formed by resin casting is arranged on the iron core 18, and a low-voltage outlet terminal 7 and a high-voltage outlet terminal 8 are installed on the top of the box body 1. The outlet terminal 7 and the high voltage outlet terminal 8

Example Embodiment

[0043] Example 2:

[0044] A method for preparing a resin cast dry-type distribution transformer, comprising the following steps:

[0045] S1. Making the mixed main material: Grind the silicon micropowder into 400 mesh, 500 mesh, and 600 mesh, dry the silicon micropowder and the coil at the same time, pour the dried silicon micropowder into the mixing kettle, and then pour it into the mixing kettle Add epoxy resin, mix epoxy resin and silicon micropowder evenly, then heat up to 75-82°C, and vacuumize at the same time, the vacuum degree is -0.08-0.1MPa, to obtain the mixed main material;

[0046] S2. Making pouring liquid: Add curing agent, flame retardant, and plasticizer to the mixed main ingredients, mix and stir for 40-90 minutes, heat while stirring, so that the temperature rises to 85-91°C, and Heating under vacuum for 200-300 minutes, the vacuum degree is -0.08-0.1MPa to prepare pouring liquid;

[0047] S3. Curing treatment: Put the coil into the mold, after adjusting the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap