Automobile body coating method capable of reducing VOC emission

A technology of automobile body and coating method, which is applied to the device, coating, special surface and other directions of coating liquid on the surface, can solve the problem of high VOC emission, and achieve the effect of reducing VOC emission and reducing VOC emission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

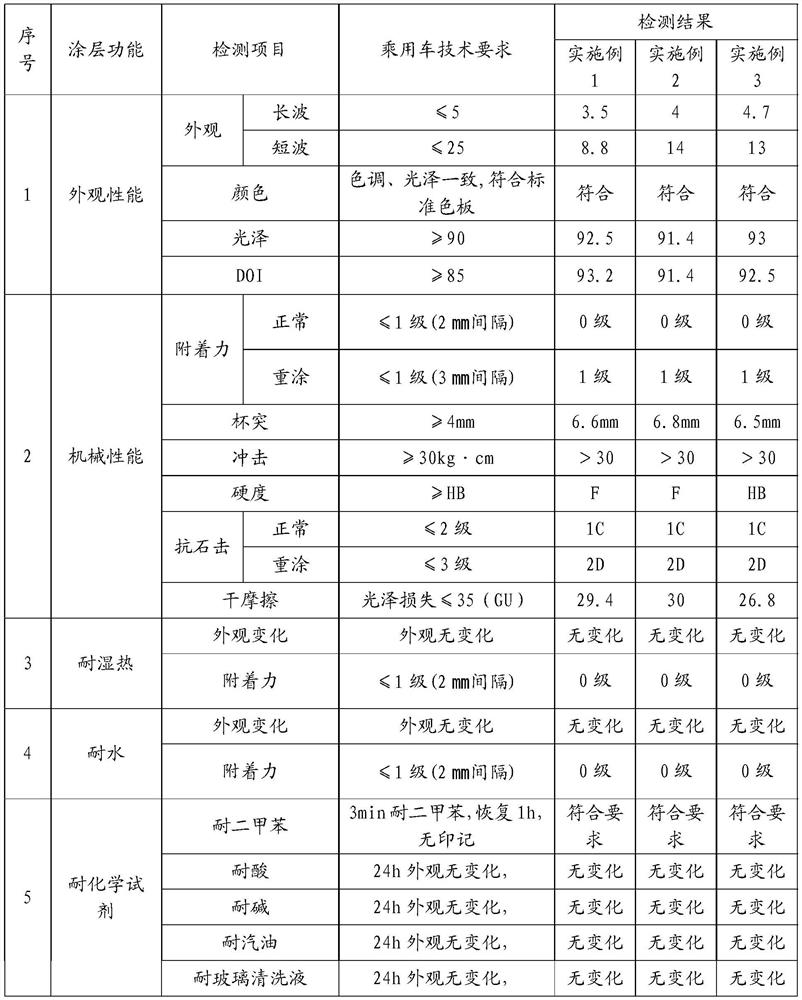

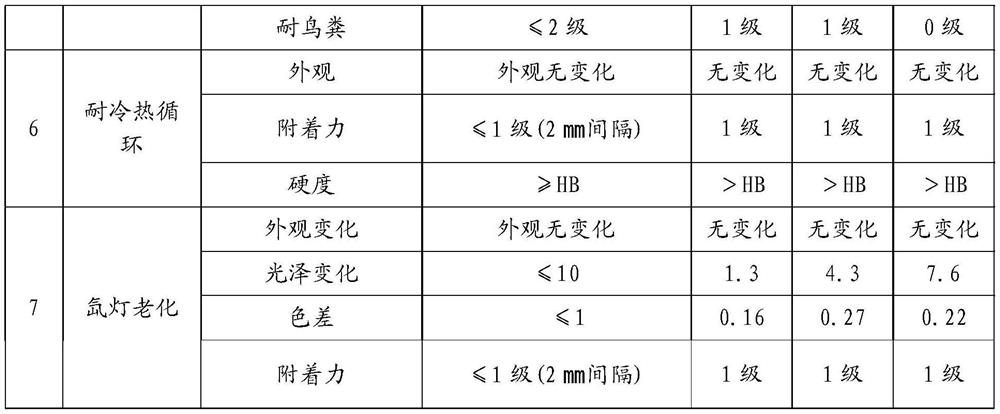

Embodiment 1

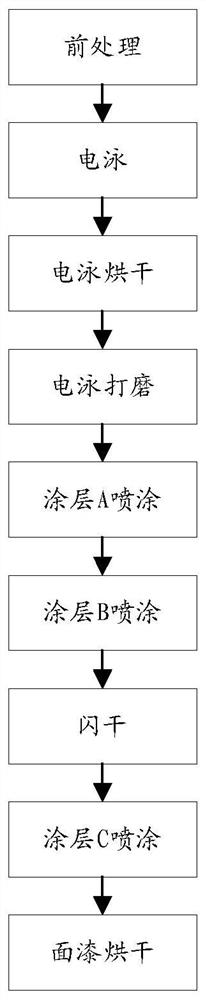

[0122] Embodiment 1 of the present application provides a kind of automobile body coating method that can reduce VOC emission, comprises the following steps:

[0123] 1. Phosphating pretreatment:

[0124] (1) Pre-washing: use industrial water at a temperature of 40°C to spray the car body, the spray time is 25s, and the spray pressure is 0.1MPa;

[0125] (2) Pre-degreasing: Spray the car body with the pre-degreasing tank solution, the spraying time is 50s, the spray pressure is 0.25MPa, the temperature of the pre-degreasing tank solution is 45°C, and the pH value of the pre-degreasing tank solution is 13; The liquid is an alkaline surfactant;

[0126] (3) Degreasing: immerse the car body in a degreasing bath with a pH value of 13, the immersion time is 200s, the surface flow circulation pressure is 0.1MPa, and the temperature of the degreasing bath is 45°C; the degreasing bath is an alkaline surfactant;

[0127] (4) The first water washing: immerse the car body in industrial wa

Embodiment 2

[0159] Embodiment 2 of the present application provides a kind of automobile body coating method that can reduce VOC emission, comprises the following steps:

[0160] 1. Film pretreatment:

[0161] (1) Pre-washing: use industrial water at a temperature of 45°C to spray the car body, the spray time is 25s, and the spray pressure is 0.12MPa;

[0162] (2) Pre-degreasing: Spray the car body with the pre-degreasing tank solution, the spraying time is 55s, the spray pressure is 0.22Pa, the temperature of the pre-degreasing tank solution is 45°C, and the pH value of the pre-degreasing tank solution is 11; Alkaline surfactant is selected for the liquid;

[0163] (3) Degreasing: Immerse the car body in the degreasing tank solution for 220s, the surface flow circulation pressure of the degreasing tank solution is 0.09MPa, the temperature of the degreasing tank solution is 45°C, and the pH value of the degreasing tank solution is 10; the degreasing tank solution is selected Alkaline surfa

Embodiment 3

[0192] Embodiment 3 of the present application provides a kind of automobile body coating method that can reduce VOC emission, comprises the following steps:

[0193] 1. Phosphating pretreatment:

[0194] (1) Pre-washing: use industrial water at a temperature of 45°C to spray the car body, the spray time is 25s, and the spray pressure is 0.12MPa;

[0195] (2) Pre-degreasing: Spray the car body with the pre-degreasing tank solution, the spraying time is 35s, the spray pressure is 0.28MPa, the temperature of the pre-degreasing tank solution is 45°C, and the pH value of the pre-degreasing tank solution is 13; The liquid is an alkaline surfactant;

[0196] (3) Degreasing: immerse the car body in a degreasing bath with a pH value of 13, the immersion time is 200s, the surface flow circulation pressure is 0.1MPa, and the temperature of the degreasing bath is 45°C; the degreasing bath is an alkaline surfactant;

[0197] (4) The first water washing: immerse the car body in industrial w

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap