Double high axial motor capable of effectively reducing back electromotive force torque ripple

A back-EMF, axial motor technology, applied in electric components, electrical components, electromechanical devices, etc., can solve the problems of stator core deformation, high speed, strong torque pulsation electromagnetic noise, etc., to reduce back-EMF, power density, etc. High, lightweight effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

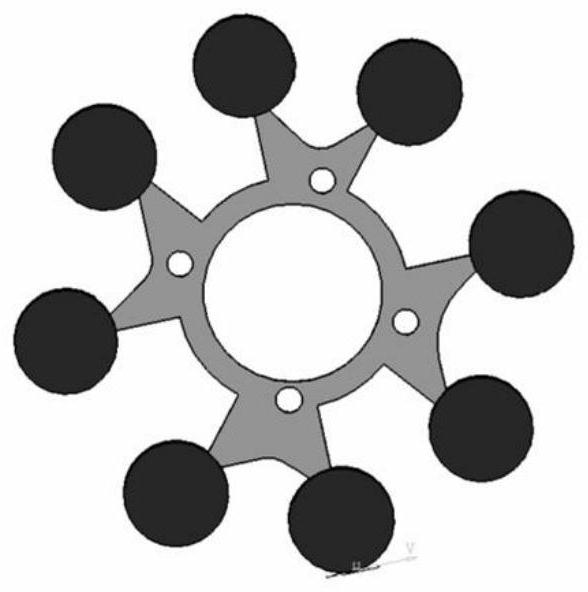

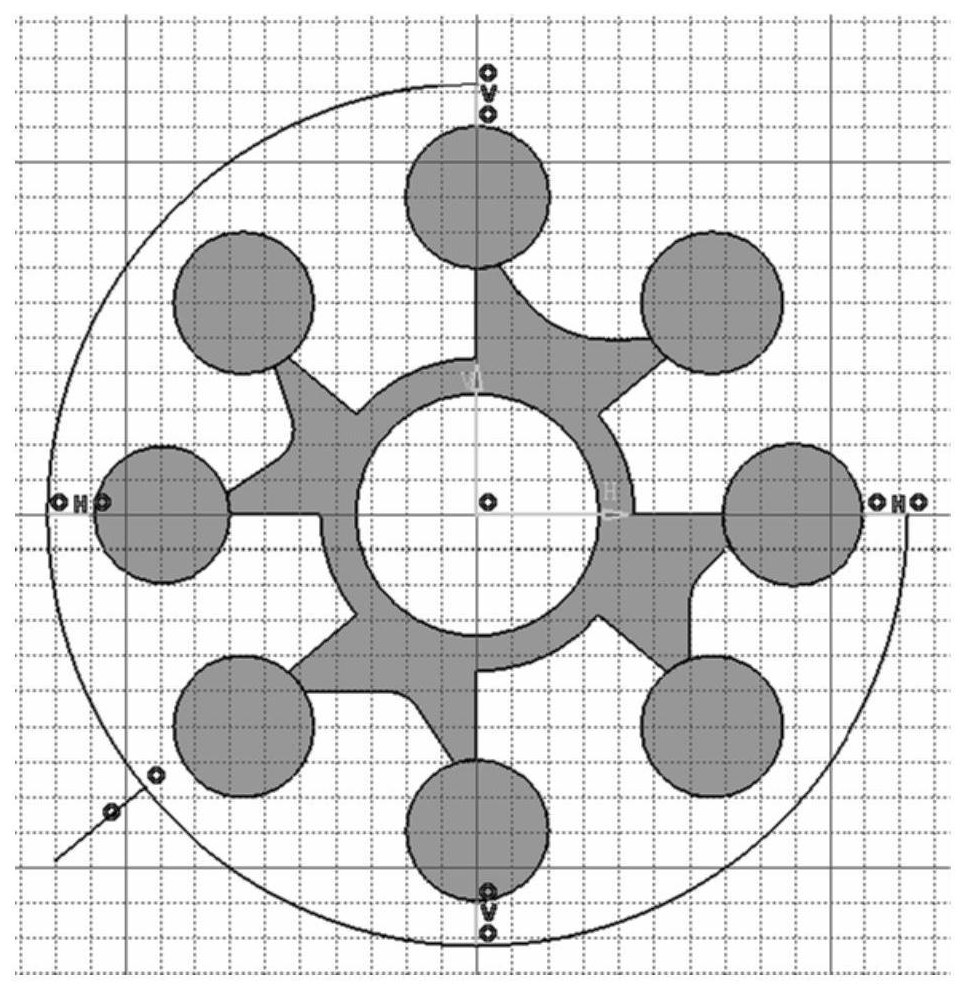

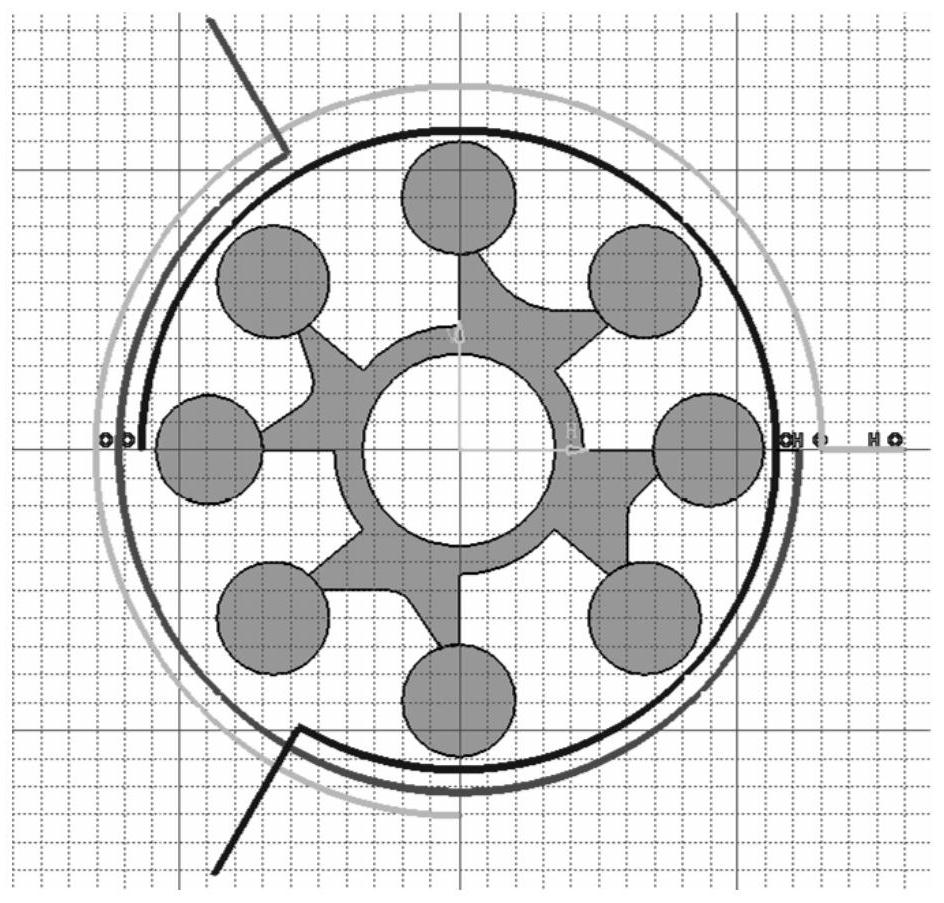

[0016] This embodiment involves a double-high axial motor that can effectively reduce back electromotive force torque ripple, such as Figure 1 to Figure 7 As shown, the motor includes a segmented armature 1, a rotor disk 2, a bearing pressure plate 3, an iron core 4, and a stator bar 5. It is characterized in that the iron core 4 of the segmented armature 1 is separated by an axial motor The bearing pressure plate 3 fixes the bearing on the stator, the segmented armature 1 uses wire rods to fix the iron core, and connects to the outer motor casing, the iron core 4 uses soft magnetic composite materials, and according to the number of poles in turn Design the curved surface, set the radian to be small or not set if it is closer to the incoming line end, set a suitable arc for the farther from the incoming line end, increase the saliency rate, and reduce the influence of inter-electrode resistance on the back electromotive force. Iron core 4 uses The stator bar 5 is fixed, and the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap