Grinding method of granular medicine for department of hepatobiliary surgery

A grinding method and particle technology, which is applied in the medical field, can solve the problems of waste of grinding resources, single grinding mode, and failure to distinguish granular drugs with different hardness, etc., and achieve the effect of improving grinding efficiency and optimal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

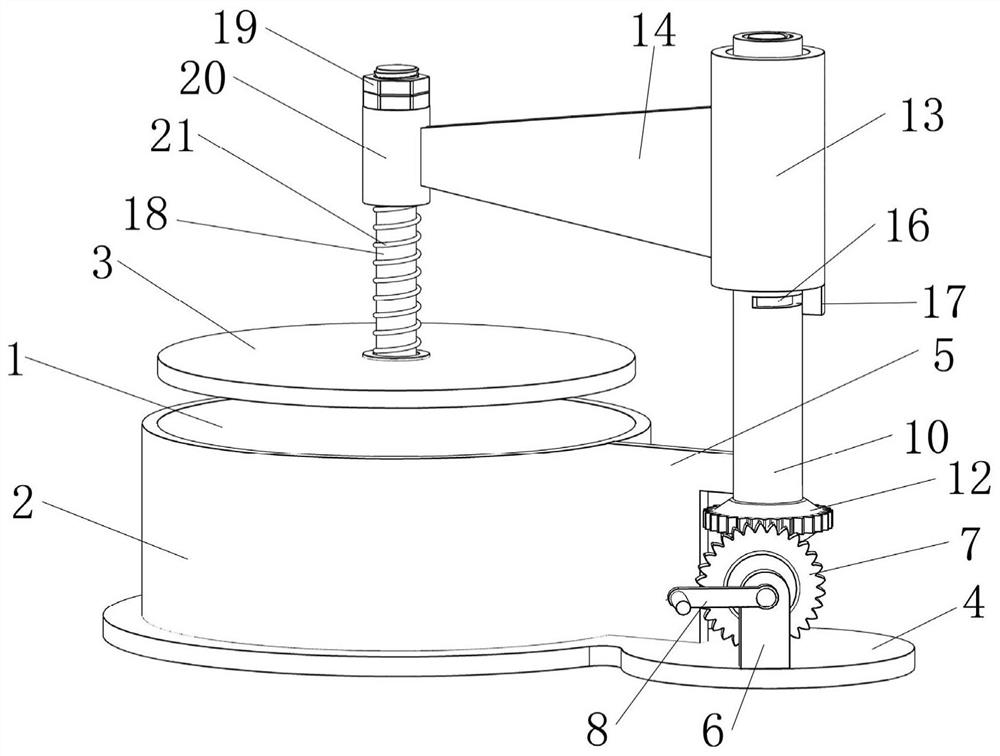

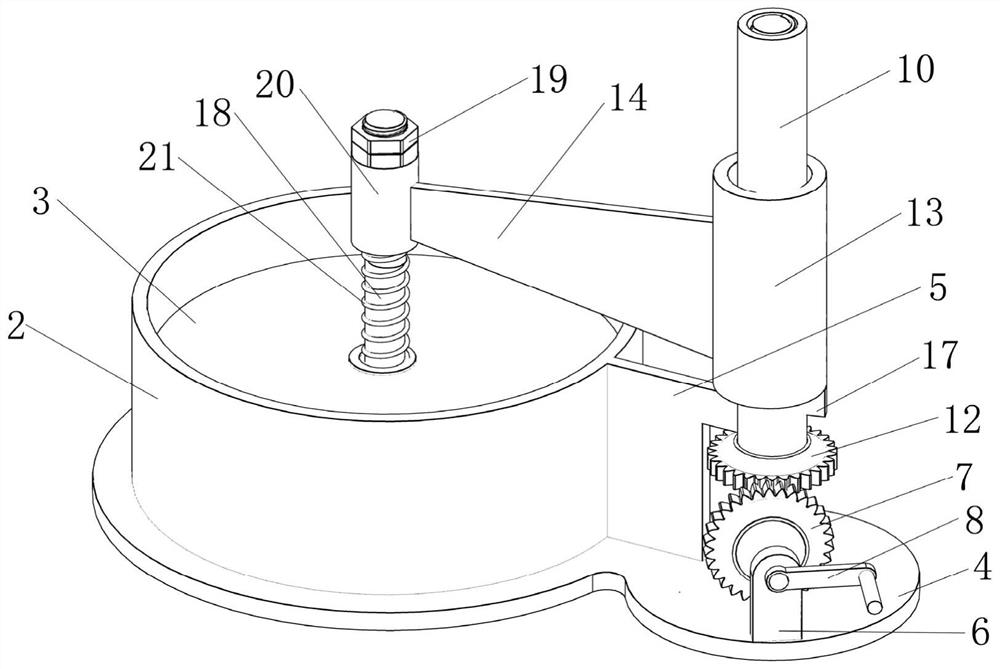

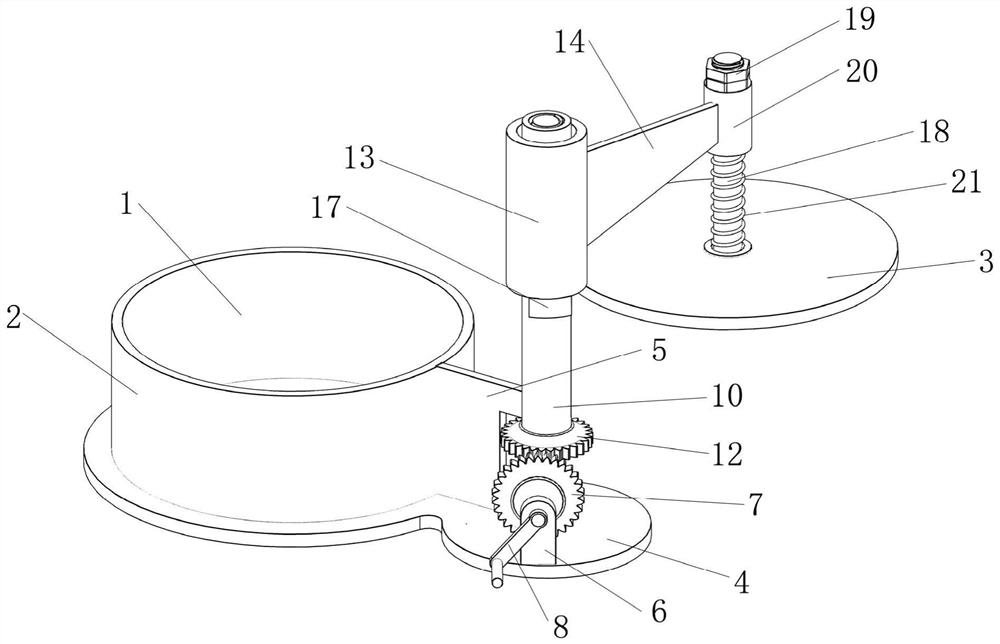

[0026] Embodiment one: if Figure 1 to Figure 4 As shown, the grinding method of granular medicine for hepatobiliary surgery in this embodiment includes a machine base 2 with a grinding chamber 1 and a grinding disc 3 located in the grinding chamber 1, the grinding chamber 1 is cylindrical, and the grinding disc 3 is disc-shaped and It is adapted to the shape of the grinding chamber 1, so that when the grinding disc 3 is pressed down, the granular medicine in the grinding chamber 1 can be ground into powder. One side of the machine base 2 is provided with a bottom plate 4 and a connecting plate 5, and the bottom plate 4 is located on the connecting plate. 5, the bottom plate 4 is fixed with a fixed frame 6, the fixed frame 6 is provided with a drive gear 7 and a rocker 8, the drive gear 7 is connected to the fixed frame 6 through the rocker 8, the connecting plate 5, and the connecting plate 5 are fixed Connecting cylinder 9 is arranged, and connecting cylinder 9 is connected wit

Embodiment 2

[0029] Embodiment 2: Different from Embodiment 1, this embodiment is such as Figure 5 Shown also includes a grinding cover 24 that can replace the grinding disc 3 , a motor 25 is arranged inside the grinding cover 24 , and a motor shaft 26 of the motor 25 runs through the bottom of the grinding cover 24 and is connected with a grinding knife 27 . When the grinding disc 3 is used, manual grinding can be realized, and when the grinding cover 24 is used, electric grinding can be realized. In this way, this embodiment has two grinding modes, and different grinding modes can be used for drugs with different hardness. Good experience. That is, the grinding machine of this embodiment has a first grinding mode and a second grinding mode. In the first grinding mode, the grinding disc 3 is fitted in the grinding chamber 1 and moves up and down in the grinding chamber 1 to grind the medicine. In the second grinding mode In this mode, the grinding cover 24 is fitted in the grinding chamber

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap