Method for positioning reverse reinforcing structure of ship by adopting ultrasonic thickness measurement

A technology of strengthening structures and ultrasonic waves, applied in ship components, ship construction, ship design, etc., can solve problems such as limited X-ray penetration ability, large and complex hull structure, unusable thick hull plates, etc., so as not to endanger human health, The effect of convenient and simple equipment operation and low equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

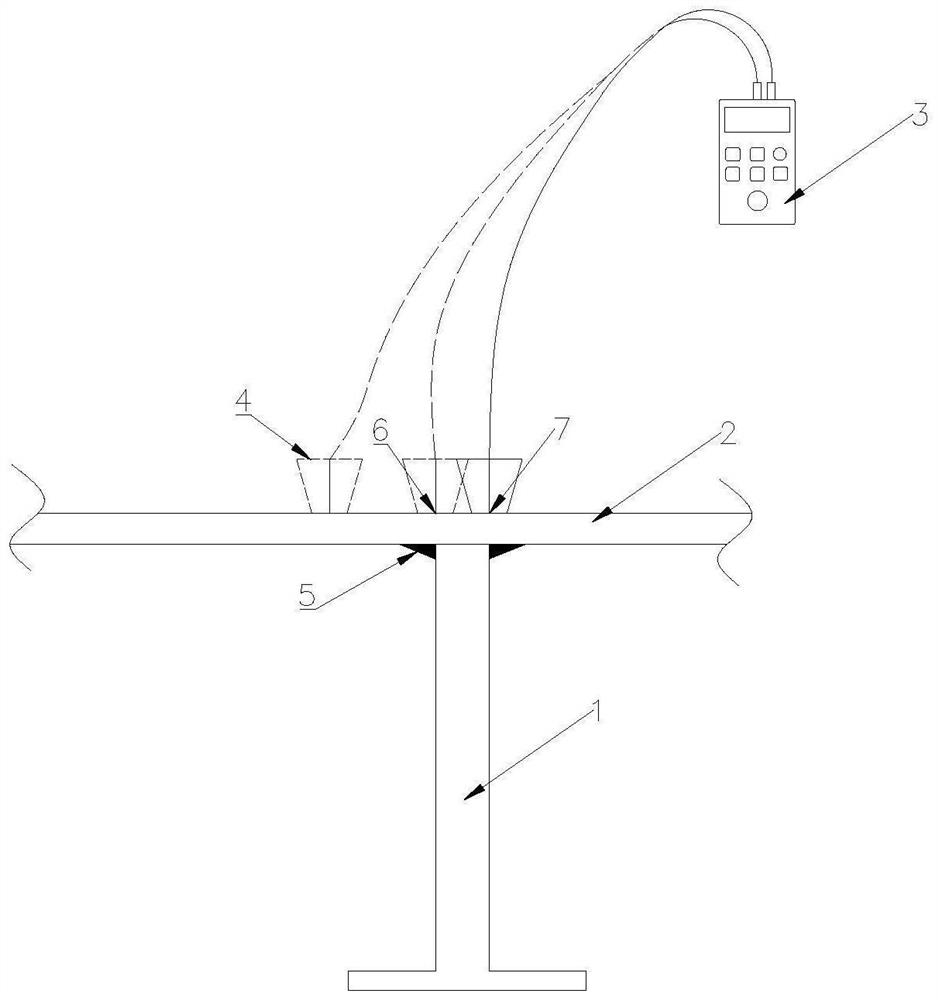

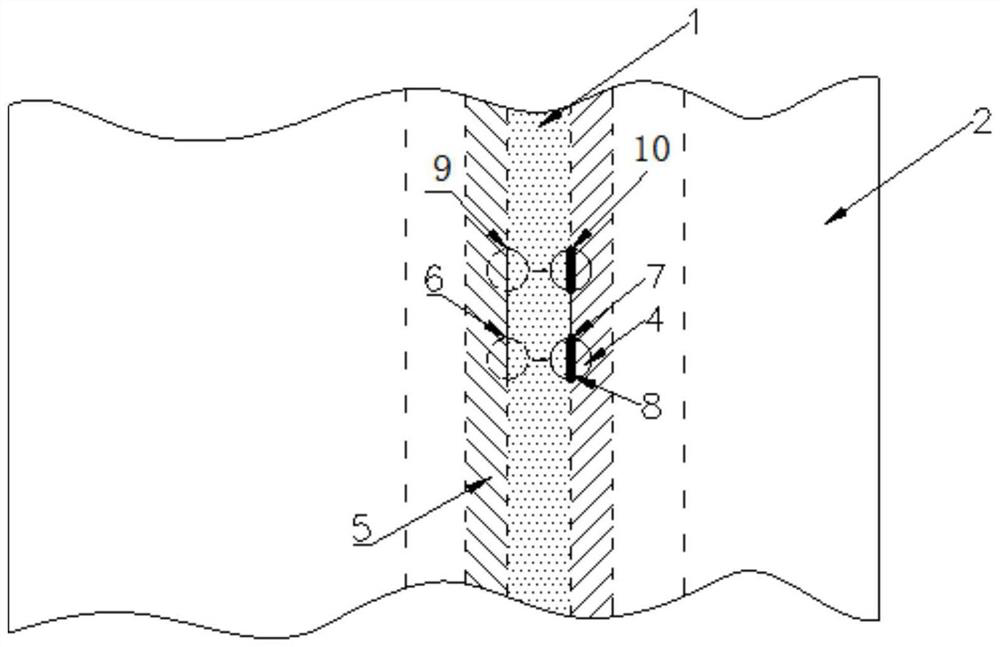

[0042] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0043] Such as Figure 1 to Figure 2 As shown, the present invention uses ultrasonic thickness measurement to locate the method for strengthening the reverse surface of the ship, comprising the following steps:

[0044] S1: On the smooth surface of the hull plate 2, a strip-shaped estimated strengthening section corresponding to the reinforcement 1 position on the opposite side of the hull plate is divided;

[0045] S2: Draw two spaced measurement lines perpendicular to the strip-shaped estimated strengthening interval, which are the first measurement line and the second measurement line;

[0046] S3: apply coupling agent for ultrasonic thickness measurement at the first measurement line and the second measurement line;

[0047] S4: Turn on the ultrasonic thickness gauge 3 and adjust to the steel material thickness measurement mode;

[004

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap