Line position-adjustable yarn conveying equipment for large-scale spinning

A wire-adjusting and large-scale technology, which is applied to the field of large-scale textile equipment with adjustable wire position, can solve the problem of cumbersome wire replacement for large-scale textile equipment, and achieve the effect of quick and convenient replacement, avoiding equipment blockage, and improving the stability of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

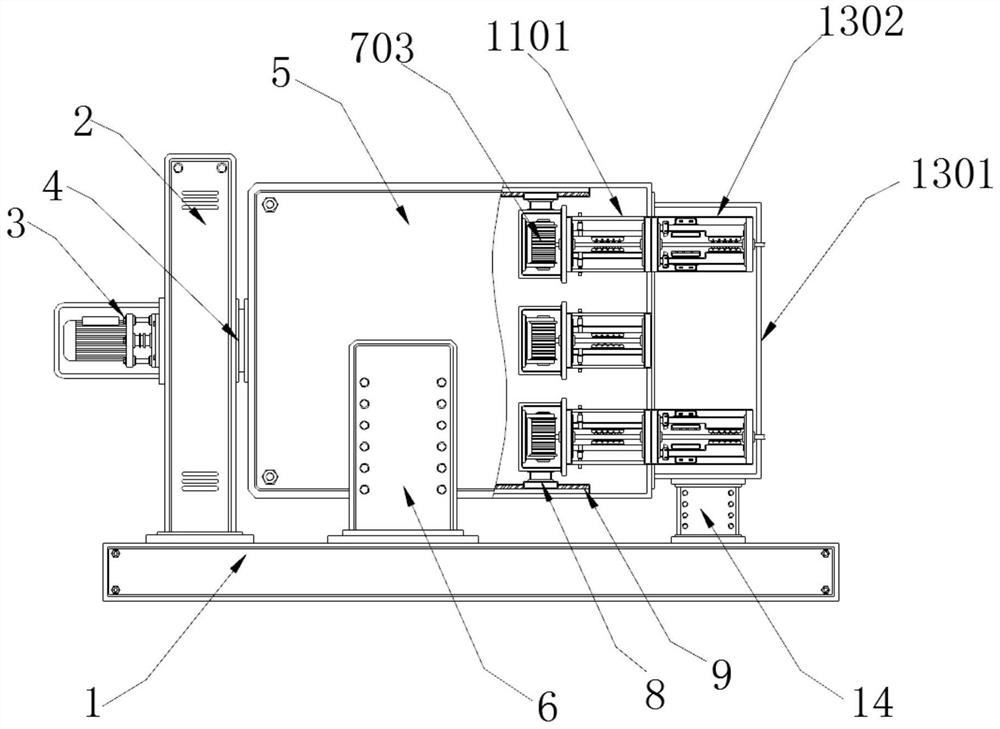

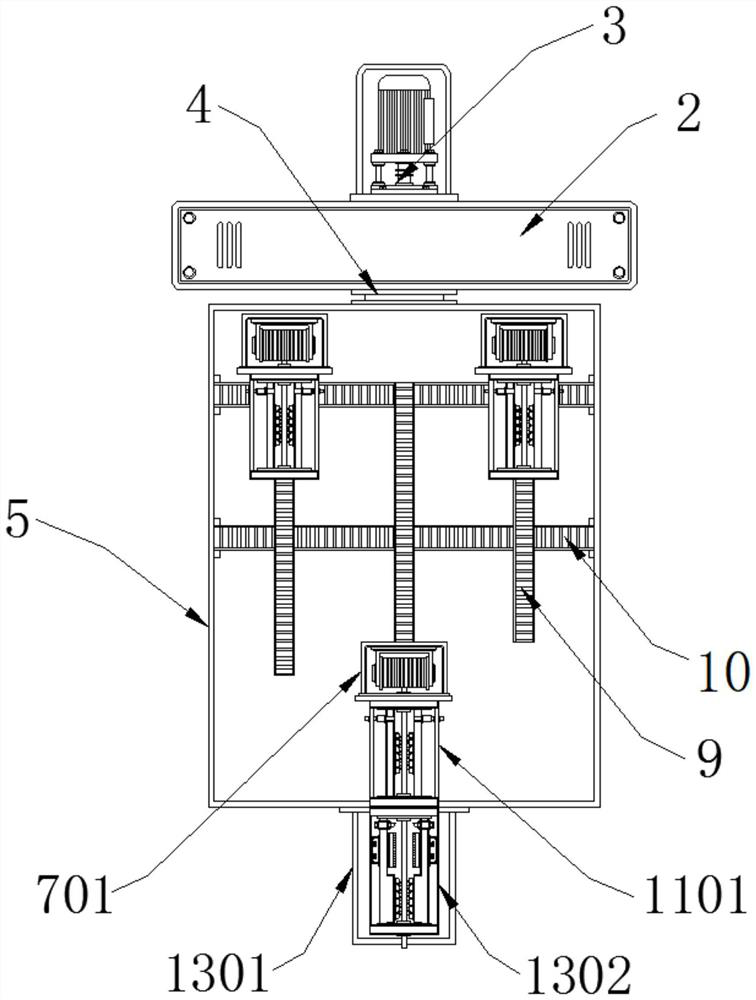

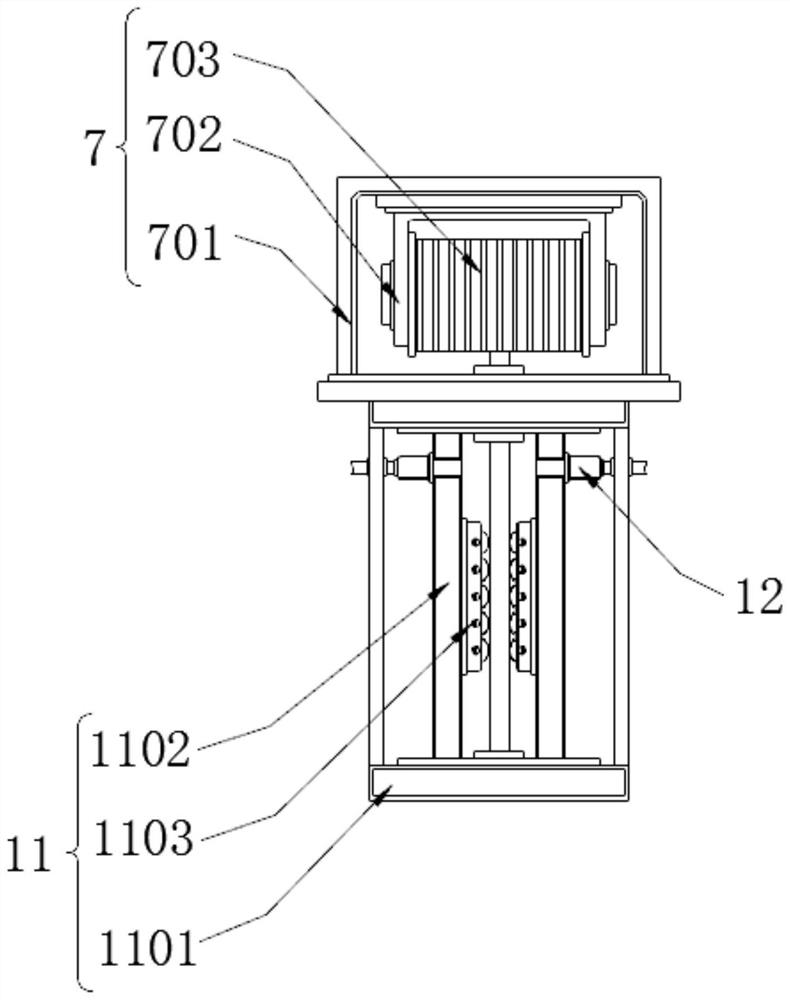

[0029] see Figure 1-7 , the present invention provides a technical solution: a large-scale textile wire transmission equipment with adjustable wire position, including a base 1, a position adjustment assembly 11 and an outlet assembly 13, a fixing seat 2 is provided on the outside of the top of the base 1, and the fixing seat The outer end of 2 is connected with motor 3, and motor 3 is connected with rotating box 5 through rotating shaft 4, and the bottom outer side of rotating box 5 is provided with supporting seat 6, and the inner side of rotating box 5 is provided with line assembly 7, and line assembly The outer end of 7 is connected with an electric sliding seat 8, and the outer end of the electric sliding seat 8 is provided with a longitudinal electric control slide plate 9, and the outer end of the longitudinal electric control slide plate 9 is connected with a horizontal electric control slide plate 10, and the position adjustment assembly 11 is arranged on the The front

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap