Non-supported ozone catalyst and use method thereof

An ozone catalytic oxidation, unloaded technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of limited strength of ozone catalysts, secondary pollution of ozone catalysts , difficult to apply on a large scale, etc., to achieve the effect of improving the effect of ozone catalytic oxidation, convenient operation and management, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

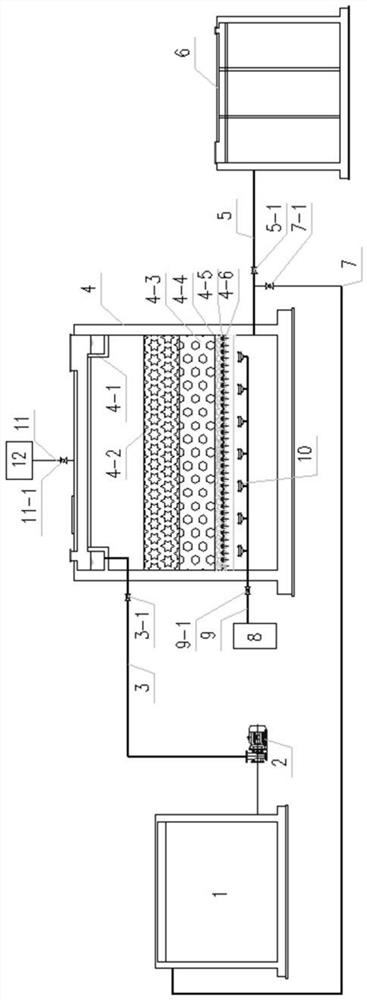

[0059] refer to figure 1 As shown, this embodiment provides a non-supported ozone catalyst titanium disk aeration system, including a water inlet tank 1, an inlet pump 2, a non-loaded ozone catalytic oxidation tank 4, a water production tank 6, an ozone generator 8, and an ozone tail gas Destruction device 12.

[0060] The water inlet tank 1 is connected with the non-load type ozone catalytic oxidation tank 4 through the water inlet pump 2, the water inlet pipe 3 and the water inlet valve 3-1.

[0061] The non-supported ozone catalytic oxidation tank 4 is divided into water inlet channel 4-1, non-supported ozone catalyst B4-2, non-supported ozone catalyst A 4-3, supporting layer 4-4, water distribution tank 4 from top to bottom Gas distribution disc 4-5, support plate 4-6.

[0062] The non-load type ozone catalytic oxidation tank 4 is connected to the water production tank 6 through the water production pipe 5 and the water production valve 5-1.

[0063] The water production p

Embodiment 2

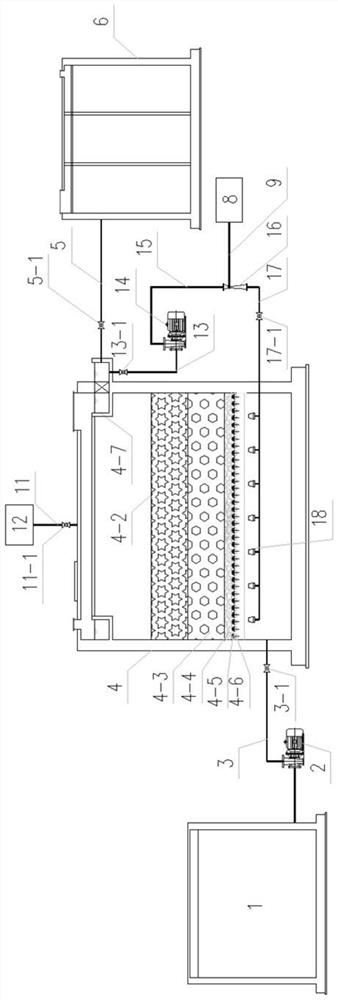

[0080] refer to figure 2 As shown, this embodiment provides a non-loaded ozone catalyst jet aeration system, including a water inlet tank 1, a water inlet pump 2, a non-loaded ozone catalytic oxidation tank 4, a water production tank 6, a circulation pump 14, and an ozone generator 8 , water injector 16, ozone tail gas destruction device 12.

[0081] The water inlet tank 1 is connected with the non-load type ozone catalytic oxidation tank 4 through the water inlet pump 2, the water inlet pipe 3 and the water inlet valve 3-1.

[0082] The non-supported ozone catalytic oxidation tank 4 is divided into an outlet channel 4-7, a non-supported ozone catalyst B4-2, a non-supported ozone catalyst A 4-3, a supporting layer 4-4, and a water distribution channel from top to bottom. Gas distribution disc 4-5, support plate 4-6.

[0083] The non-load type ozone catalytic oxidation tank 4 is connected to the water production tank 6 through the water production pipe 5 and the water productio

Embodiment 3

[0101] Same as Example 1, the only difference is that the volume ratio of non-supported ozone catalyst A and non-supported ozone catalyst B is 5:1.

[0102] Use the method of this embodiment to treat the biochemical effluent of certain pharmaceutical wastewater. The raw water COD is 200-300mg / L, after being treated by this system, the COD is 108-171mg / L, the COD removal rate is 43-46%, the ozone amount / COD removal amount is 1.8-2.0, and the waste water is obtained after being treated by this system Good COD removal effect and ozone utilization efficiency.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap