Zero-discharge treatment method and system for mine strong brine

A treatment system and treatment method technology are applied in the field of mine concentrated brine zero discharge treatment method and system field, which can solve the problems of high operating cost, low quality, difficult treatment of high-salt waste water, etc., so as to improve the water recovery rate and protect the environment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

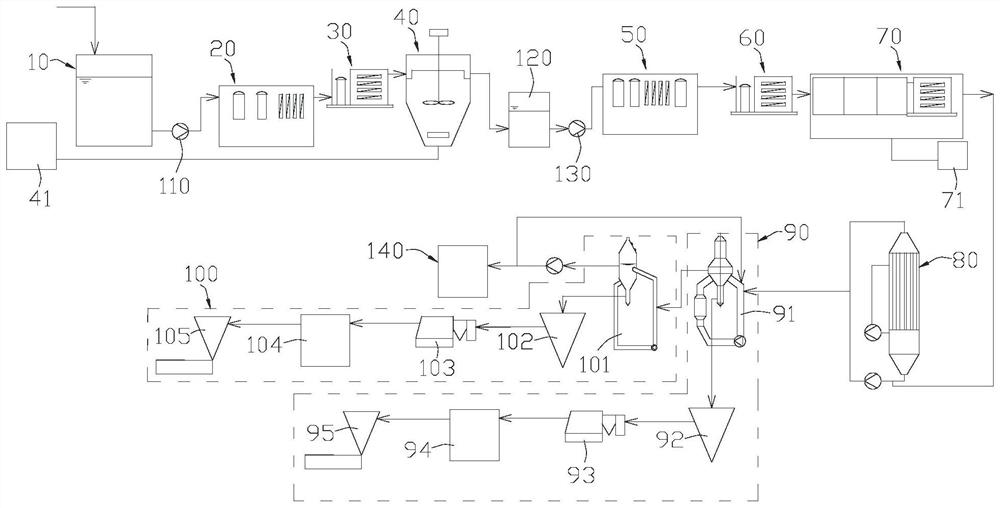

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

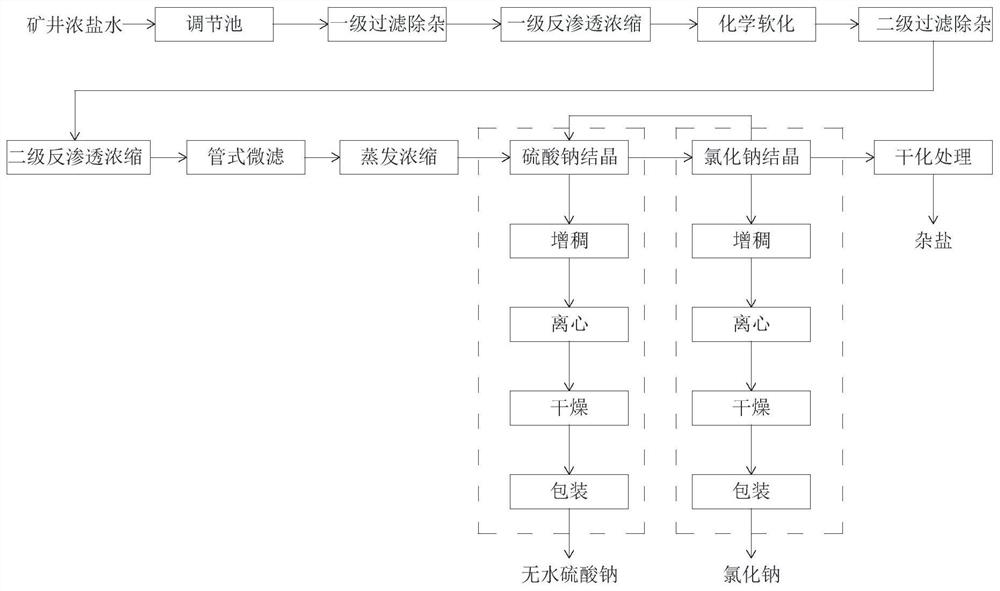

[0033] Such as figure 1 As shown, the mine concentrated brine zero discharge treatment method of an embodiment of the present invention comprises the following steps:

[0034] S1. Firstly, the mine concentrated brine is subjected to primary filtration and impurity removal treatment, and then primary reverse osmosis concentration is performed to obtain primary reverse osmosis product water and primary reverse osmosis concentrated water.

[0035] Among them, the mine concentrated brine is pre-stored in the regulating tank, and then the mine concentrated brine in the regulating tank is output to perform primary filtration and impurity removal treatment to remove suspended solids, oil and other substances.

[0036] The concen

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap