Beam body embedded part inspection system and method

An inspection system and inspection method technology, applied in the field of beam body embedded parts inspection system field, can solve the problems of large precision error of embedded parts detection, force influence of beam body structure, and difficulty of beam body reinforcement into molds, etc. The effect of improving measurement efficiency, improving measurement accuracy and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

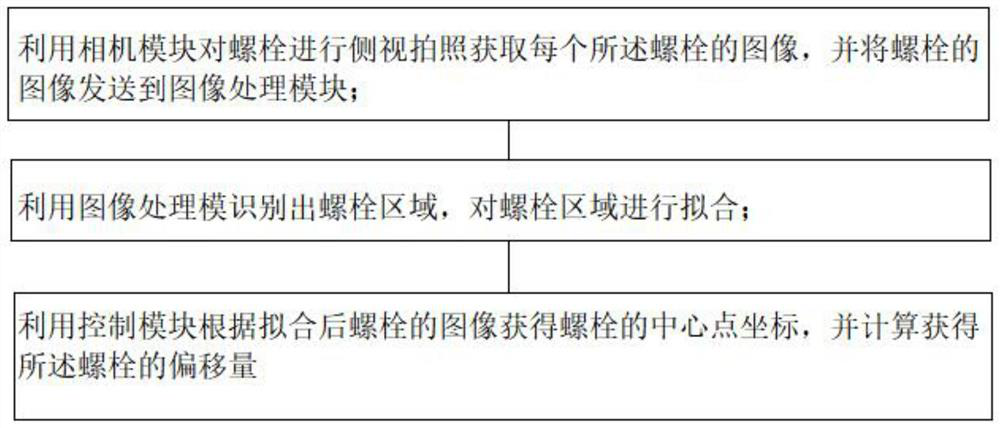

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be clearly and completely described below with reference to the accompanying drawings. Obviously, the described embodiments are part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

[0022] An embodiment of the present invention provides an inspection system for beam embedded parts, wherein the embedded parts include a base plate and bolts, the base plate is provided with a plurality of bolt holes, and the bolts are respectively installed in each of the bolt holes. A plating layer is provided on the surface of the bottom plate. The system includes an inspection platform for placing embedded parts, and a camera module, an image processing module and a control module arranged on one side

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap