Forming process of three-dimensional window type scene-permeable label

A molding process and three-dimensional window technology, applied in the direction of identification devices, instruments, stamps, etc., can solve the problems of poor softness and flatness of labels, insufficient patterns, and many die-cutting processes, etc., to achieve good softness and flatness, Relieves visual fatigue and distraction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

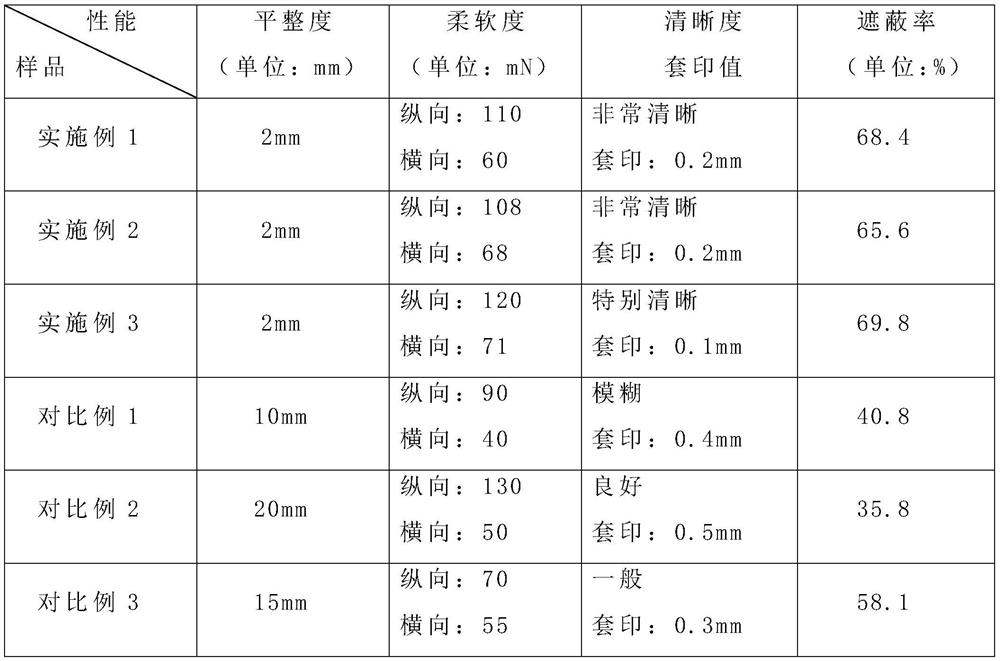

Embodiment 1

[0029] The molding process of the three-dimensional window type perspective label involved in the present embodiment includes the following steps:

[0030] S1, front printing

[0031] Select shrink film material, first corona treatment on the front and back of the shrink film, and use gravure matte oil combined with flexographic printing to display the basic information of the label, such as brand origin, origin, barcode, logo, etc. on the surface of the shrink film, among which the printing process , the film input tension is 90mN / m, and the film output tension is 100mN / m;

[0032] S2, mask printing

[0033] Three layers of white ink are used for printing with line anilox rollers, and they show the ink loading from shallow to deep, highlight the layers and outline the contours of the developed areas, so that the shrink film cannot be completely transparent visually, and the line anilox The rollers are 260 lines, 220 lines and 80 lines respectively, and the corresponding in

Embodiment 2

[0040] The label forming process involved in this embodiment is basically the same as that in Embodiment 1, with the following differences.

[0041] In S1, the film feed tension was 88 mN / m and the film exit tension was 105 mN / m.

[0042] In S2, the line anilox rollers are 250 lines, 240 lines and 100 lines respectively, and the corresponding ink load is 6.5cm 3 / m 2 , 6.8cm 3 / m 2 , 12cm 3 / m 2 .

[0043] The number of lines of the anilox roll in S3 is 450 lines.

Embodiment 3

[0045] The label forming process involved in this embodiment is basically the same as that in Embodiment 1, with the following differences.

[0046] In S1, the film feed tension was 92 mN / m and the film exit tension was 95 mN / m.

[0047] In S2, the line anilox rollers are 230 lines, 200 lines and 90 lines respectively, and the corresponding ink load is 6.6cm 3 / m 2 , 7.1cm 3 / m 2 , 16.6cm 3 / m 2 .

[0048] The number of lines of the anilox roll in S3 is 550 lines.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap