Integrated pump station management method, device and equipment and readable storage medium

A management method and technology of a management device, applied in the field of integrated pumping stations, can solve the problems of low management efficiency, burnt out motors, and time-consuming, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

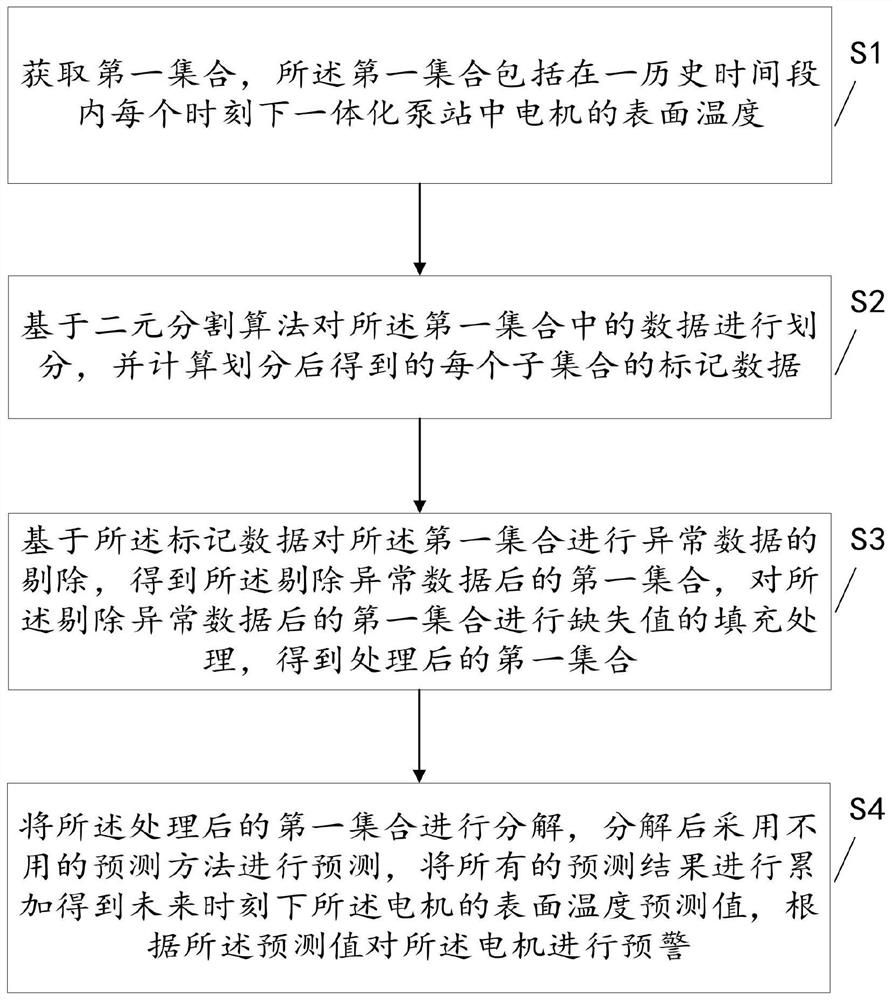

[0068] like figure 1 As shown, this embodiment provides an integrated pump station management method, the method includes step S1, step S2, step S3 and step S4.

[0069] Step S1, acquiring a first set, the first set includes the surface temperature of the motor in the integrated pumping station at each moment in a historical time period;

[0070] Step S2, divides the data in the first set based on the binary segmentation algorithm, and calculates the marked data of each subset obtained after the division;

[0071] Step S3, removing abnormal data from the first set based on the marked data to obtain a first set after removing abnormal data, and performing filling processing for missing values on the first set after removing abnormal data to obtain the processing After the first set;

[0072] Step S4: Decompose the processed first set, use a different prediction method for prediction after decomposition, and accumulate all the prediction results to obtain the predicted value of

Embodiment 2

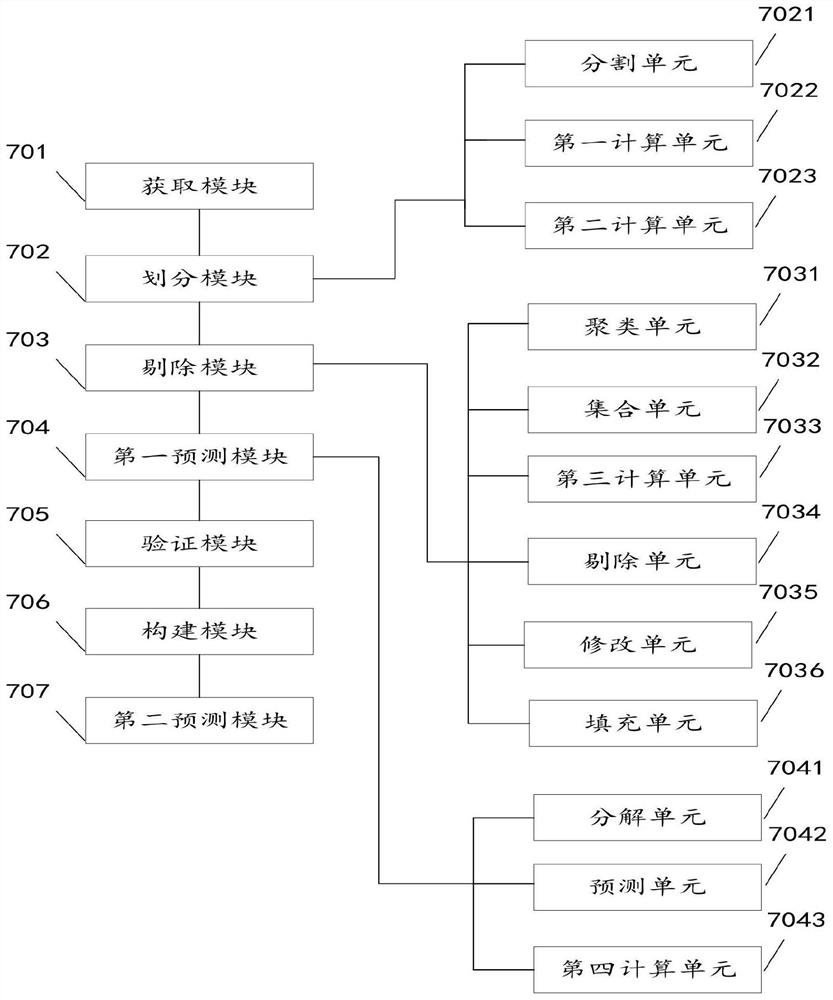

[0101] like figure 2 As shown, this embodiment provides an integrated pump station management device, the device includes an acquisition module 701 , a division module 702 , a rejection module 703 and a first prediction module 704 .

[0102] an acquisition module 701, configured to acquire a first set, where the first set includes the surface temperature of the motor in the integrated pumping station at each moment in a historical time period;

[0103] A division module 702, configured to divide the data in the first set based on a binary division algorithm, and calculate the marked data of each subset obtained after division;

[0104] Removal module 703, configured to remove abnormal data from the first set based on the marked data, obtain a first set after removing abnormal data, and perform missing value filling processing on the first set after removing abnormal data , get the first set after processing;

[0105] The first prediction module 704 is configured to decompose t

Embodiment 3

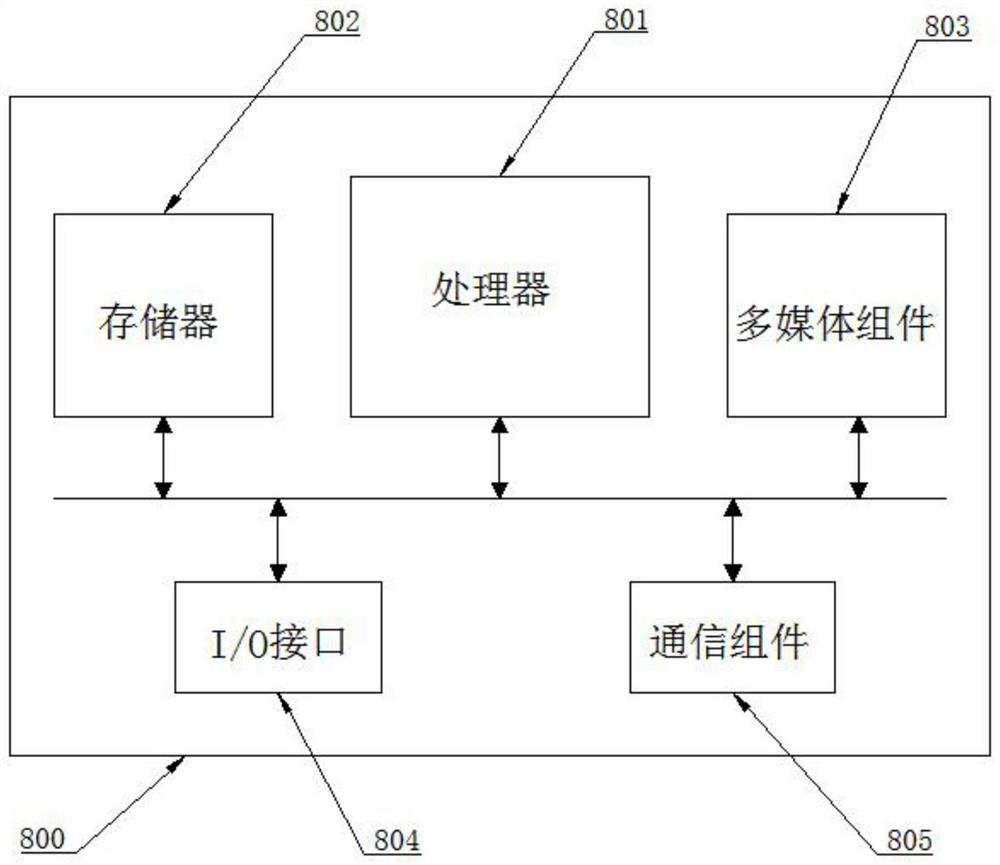

[0129] Corresponding to the above method embodiments, the embodiments of the present disclosure further provide an integrated pump station management device, and the integrated pump station management device described below and the integrated pump station management method described above may refer to each other correspondingly.

[0130] image 3 It is a block diagram of an integrated pump station management device 800 according to an exemplary embodiment. like image 3 As shown, the integrated pump station management device 800 may include: a processor 801 and a memory 802 . The integrated pump station management device 800 may also include one or more of a multimedia component 803 , an input / output (I / O) interface 804 , and a communication component 805 .

[0131] Wherein, the processor 801 is used to control the overall operation of the integrated pump station management device 800, so as to complete all or part of the steps in the above-mentioned integrated pump station

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap