Precise power utilization regulation and control terminal calibration method, device and equipment

A calibration method and electrical control technology, applied in the field of power equipment, can solve the problems of poor measurement error accuracy, not considering the full temperature effect, etc., and achieve the effect of reducing the measurement error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

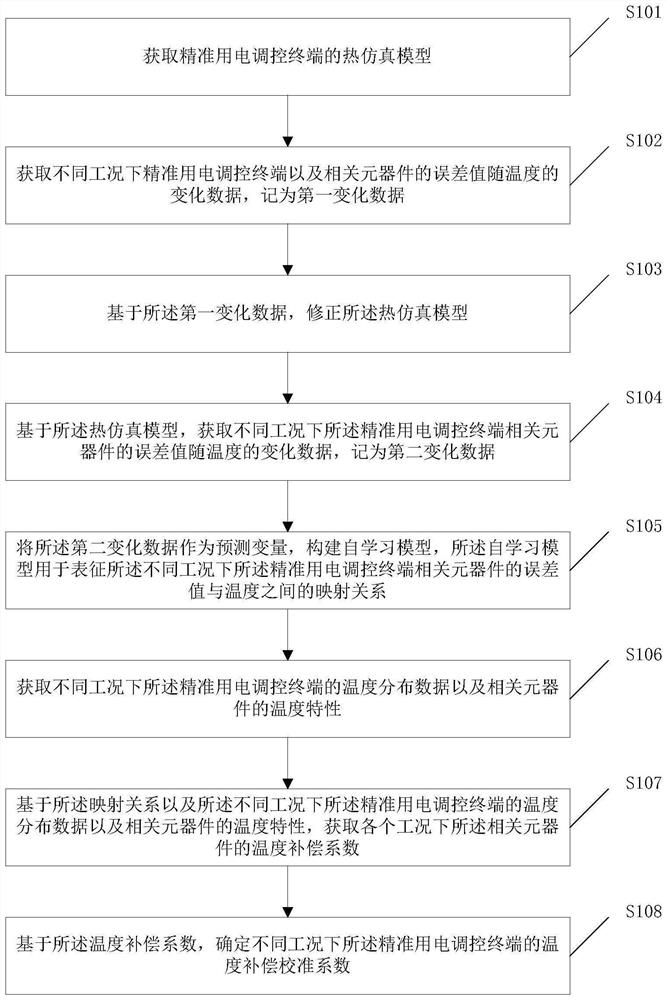

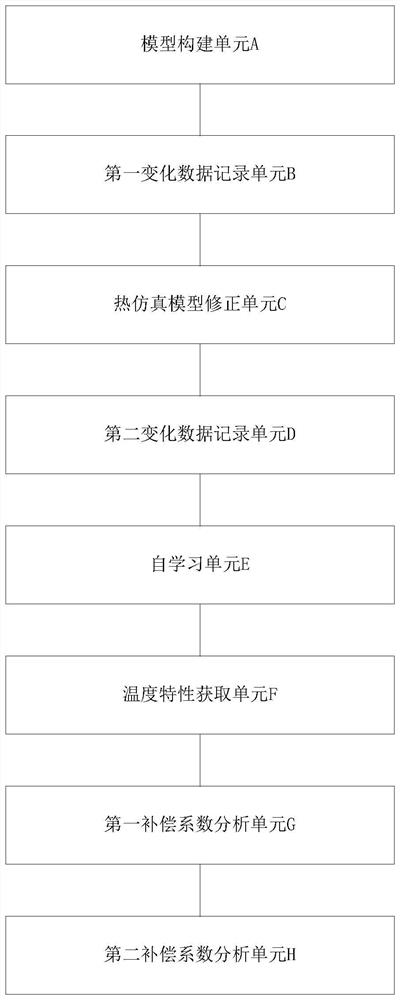

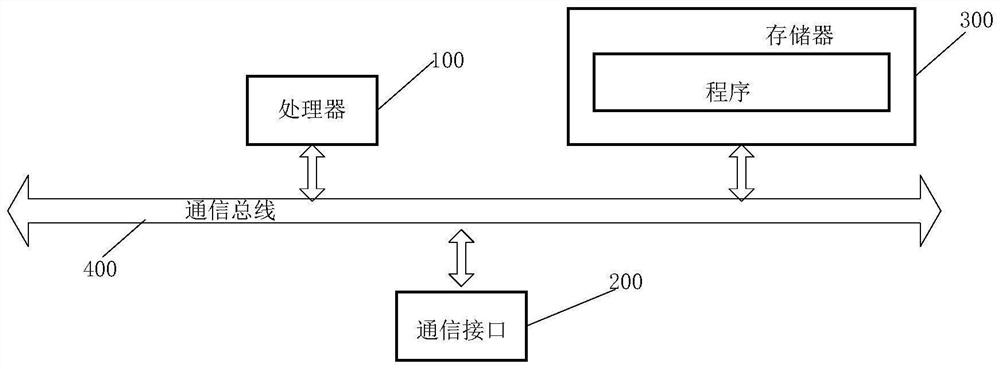

[0054]The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

[0055] In actual use, the precision power control terminal is prone to drift at room temperature due to the influence of ambient temperature on the measurement chip and sampling resistor. ) The influence of the components on the measurement error caused by the temperature change, the present invention adopts different working conditions (different voltages, currents, phase angles), and considers the accurate power consumption within the op

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap