Method for measuring imaging surface strength of lithoprint plate, lithoprint plate and packaging member of lithoprint plate

A surface strength and imaging technology, applied in the preparation of printing surface, film packaging, printing plates, etc., can solve the problems of high manufacturing cost, expensive synthetic pulp, high cost of clip material, and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Description of the preferred embodiment

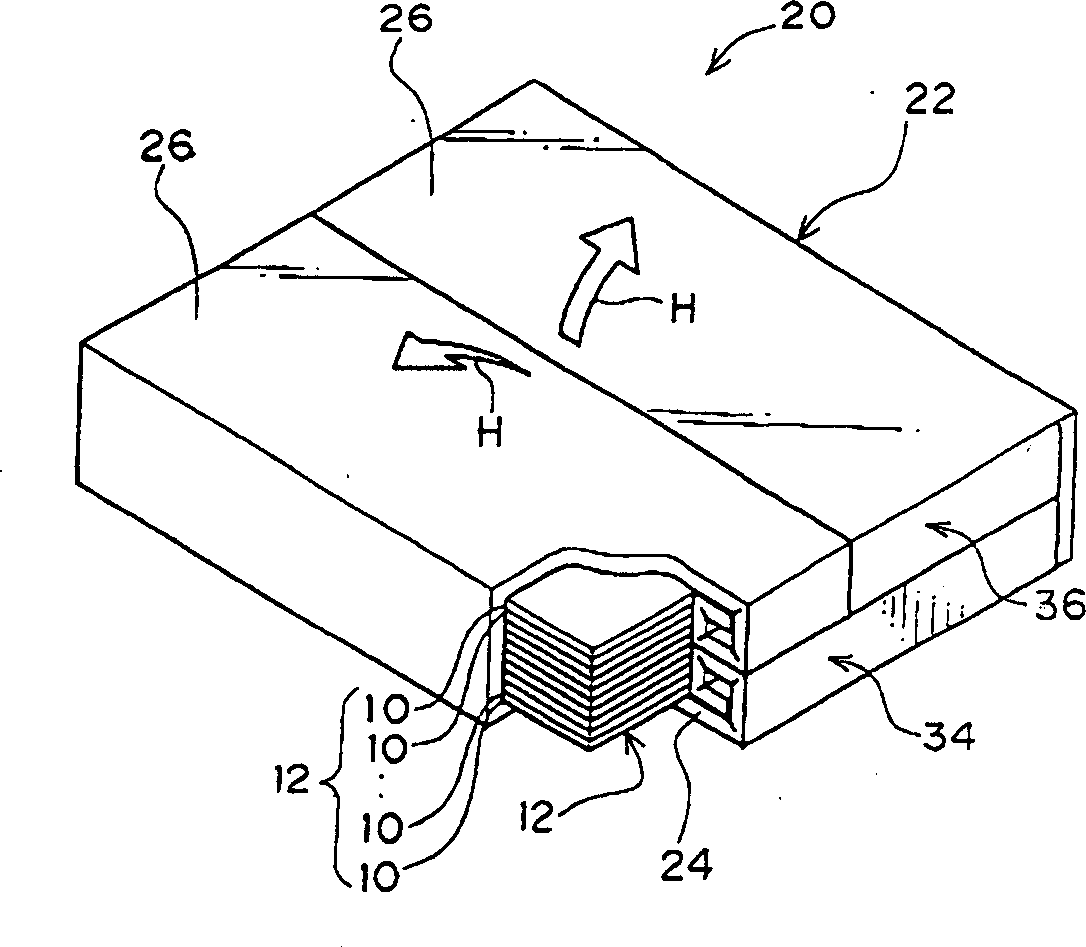

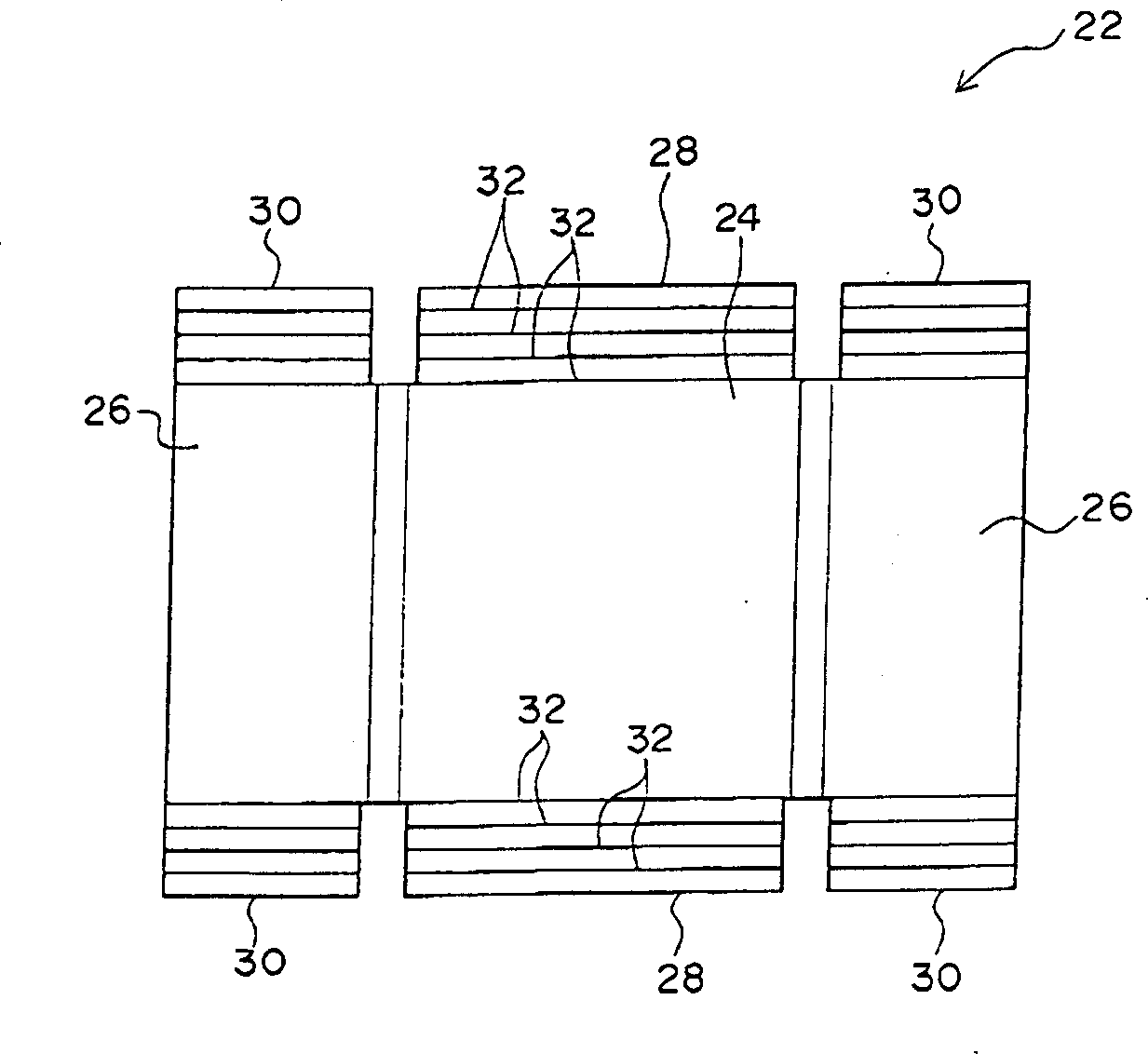

[0049] figure 1 A packing member 20 of the planographic printing plate 10 according to the first embodiment of the present invention is shown. The lithographic printing plates 10 are stacked into a stack 12 and the stack 12 is packaged in a packaging box 22 . Figure 3A and 3B represents a method of the present invention for measuring the imaged surface strength of a lithographic printing plate (hereinafter referred to as "method").

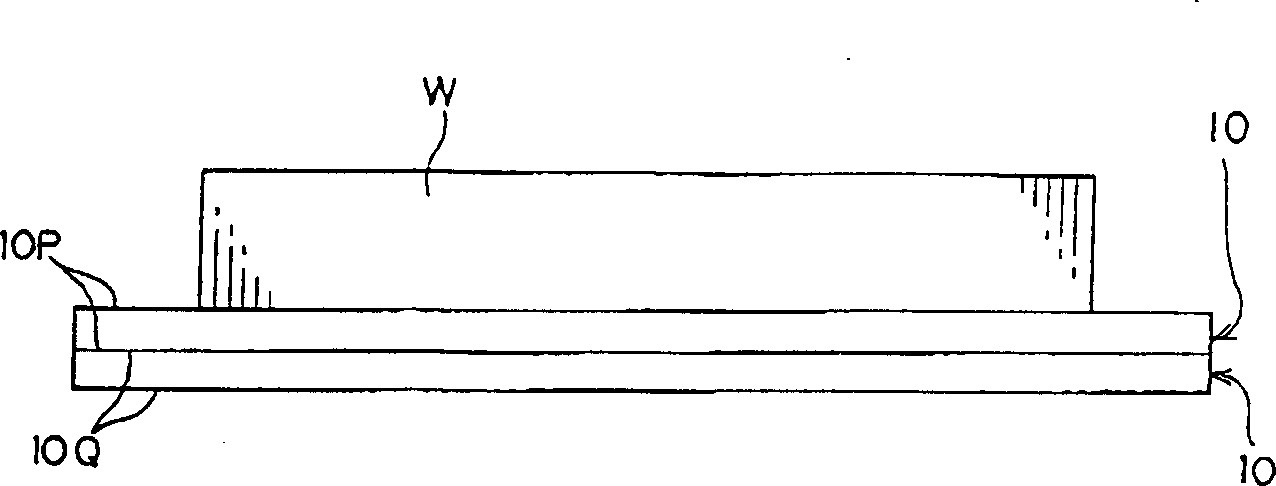

[0050] The lithographic printing plate 10 is formed by affixing a film (a photosensitive layer in the case of a photosensitive printing plate, a heat sensitive layer in the case of a thermal printing plate) to a thin rectangular aluminum support. Then, the lithographic printing plate is subjected to plate-making steps such as exposing, developing, gumming or the like, and the lithographic printing plate is loaded into a printer and ink is applied to print characters, images or the like on paper. H

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap