Balancing weight unit of ring spindle spinning frame

A technology of a balancing device and a spinning frame, which is applied to spinning machines, continuously wound spinning machines, textiles and papermaking, etc., can solve the problems of complex structure of the balancing device, inconvenient maintenance, easy fatigue of torsion bars and damage to the balancing effect, etc. , to achieve the effect of simple structure, reliable performance and simplified balance mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

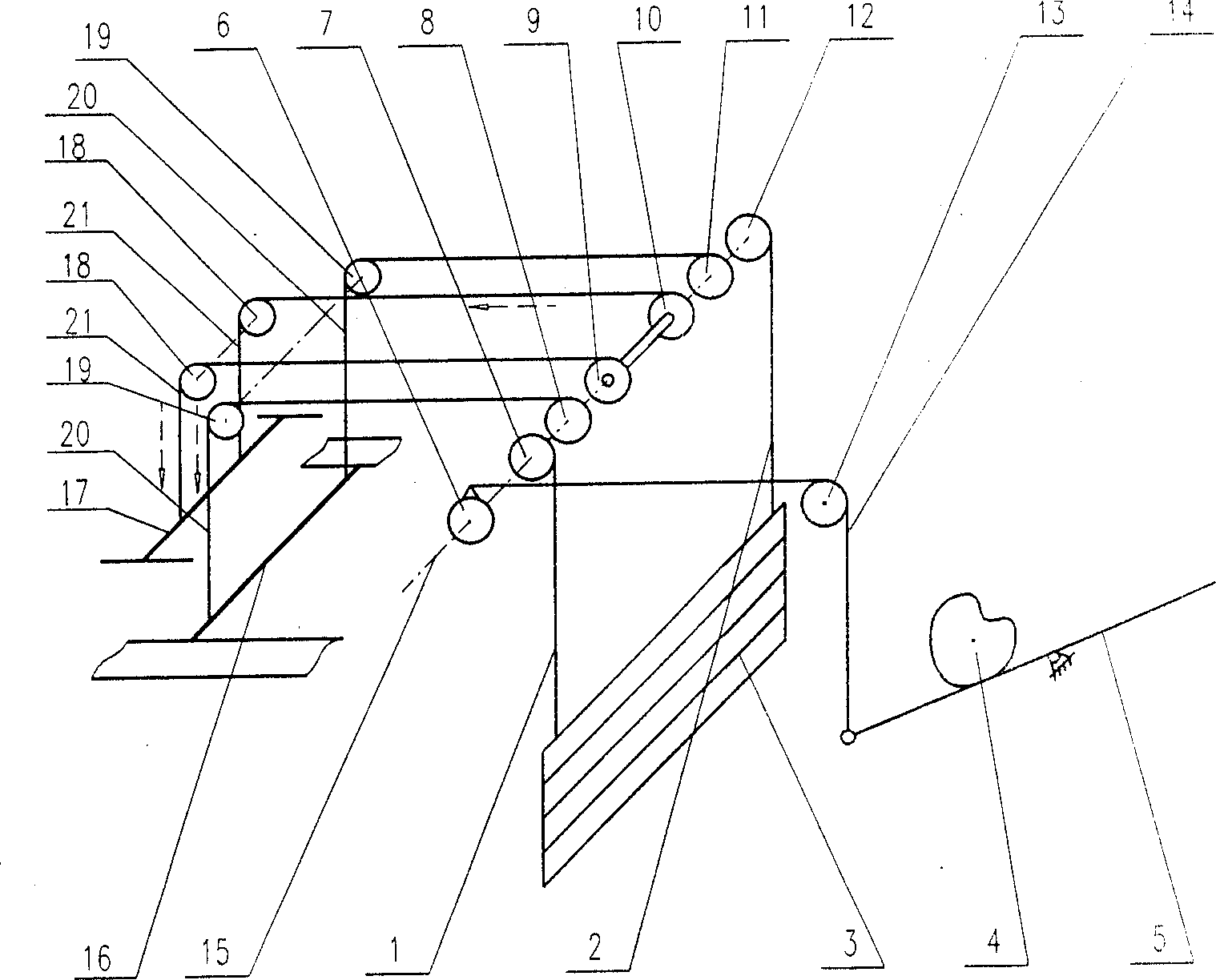

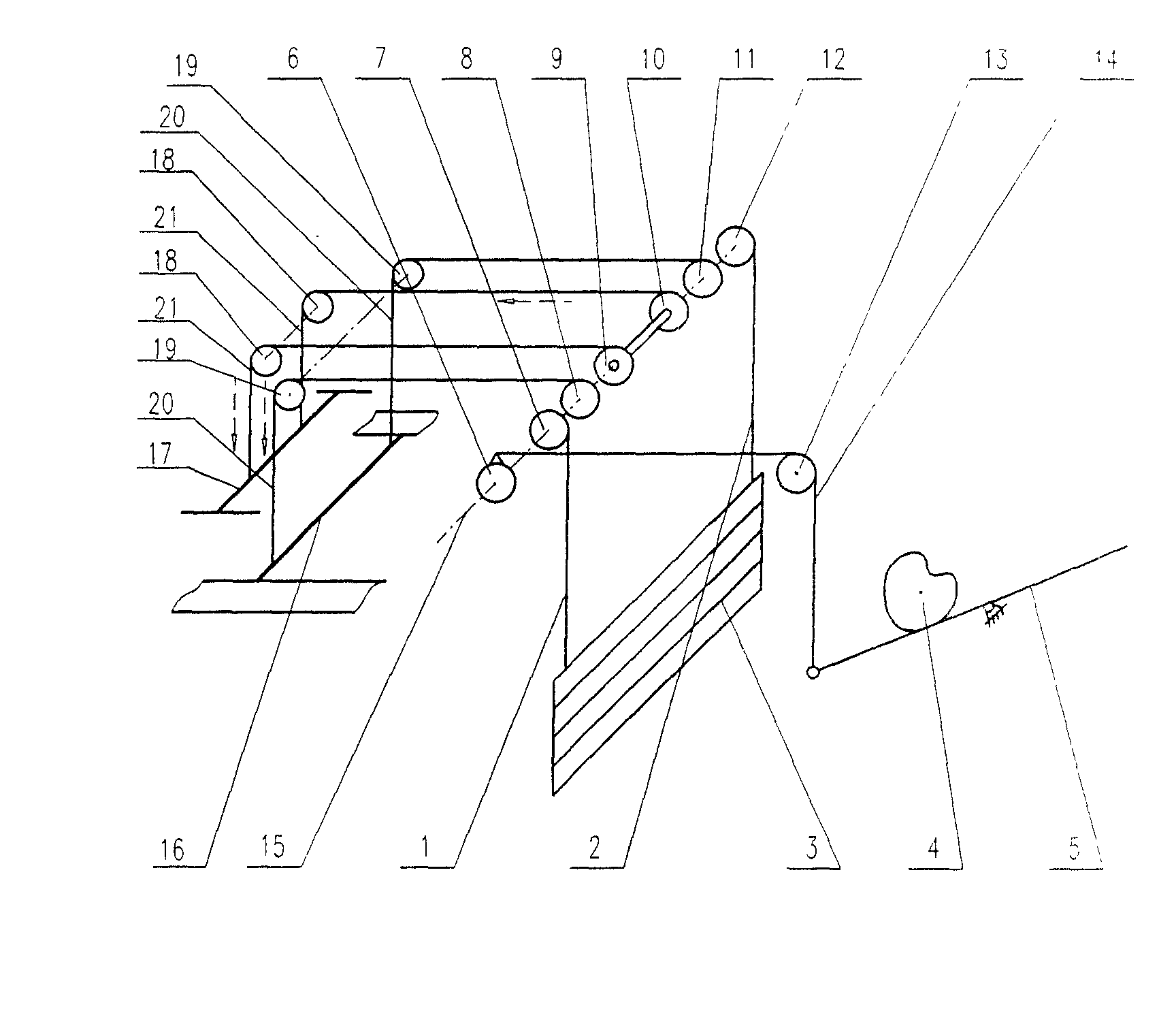

[0009] As shown in the accompanying drawings, the weight balance device of the ring spinning frame in this embodiment includes a fixed sprocket 13, a forming cam 4, a swing arm 5 in contact with the forming cam 4, and the end of the swing arm 5. The leading chain 14 that is connected and the driving mechanism that the main sprocket 6 that is connected with main driving chain 14 constitutes, is connected with driven sprocket 8,9,10,11 by driven sprocket 8,9,10,11 Lifting chain 20,21, the lifting member 16,17 that is connected with the other end of lifting chain 20,21 and the hoisting mechanism that transition sprocket wheel 18,19 constitutes. Among them, it also includes a weight balance mechanism composed of two transmission sprockets 7, 12, traction chains 1, 2, 4 counterweights 3 and an upper distribution shaft 15. The two transmission sprockets 7, 12 ar

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap