Metal foil thin-membrane wire

A metal foil and wire technology, applied in the direction of conductors, insulated conductors, insulated cables, etc., can solve the problems of not being able to be peeled off at will, affecting the appearance and strength, and easy to fall off.

Inactive Publication Date: 2004-12-08

李广东

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The original traditional wire type can no longer meet the needs of modern electronic control. In some places where wired signal control is required, traditional wires are still used as signal control lines. Not only is construction and installation difficult, waste materials and man-hours, and sometimes damage buildings The object or the machine itself affects the appearance or the strength of the building and the machine itself, shortening the service life. The thickness of the commercially available FFC flat wire is rela

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

Login to view more

Login to view more Abstract

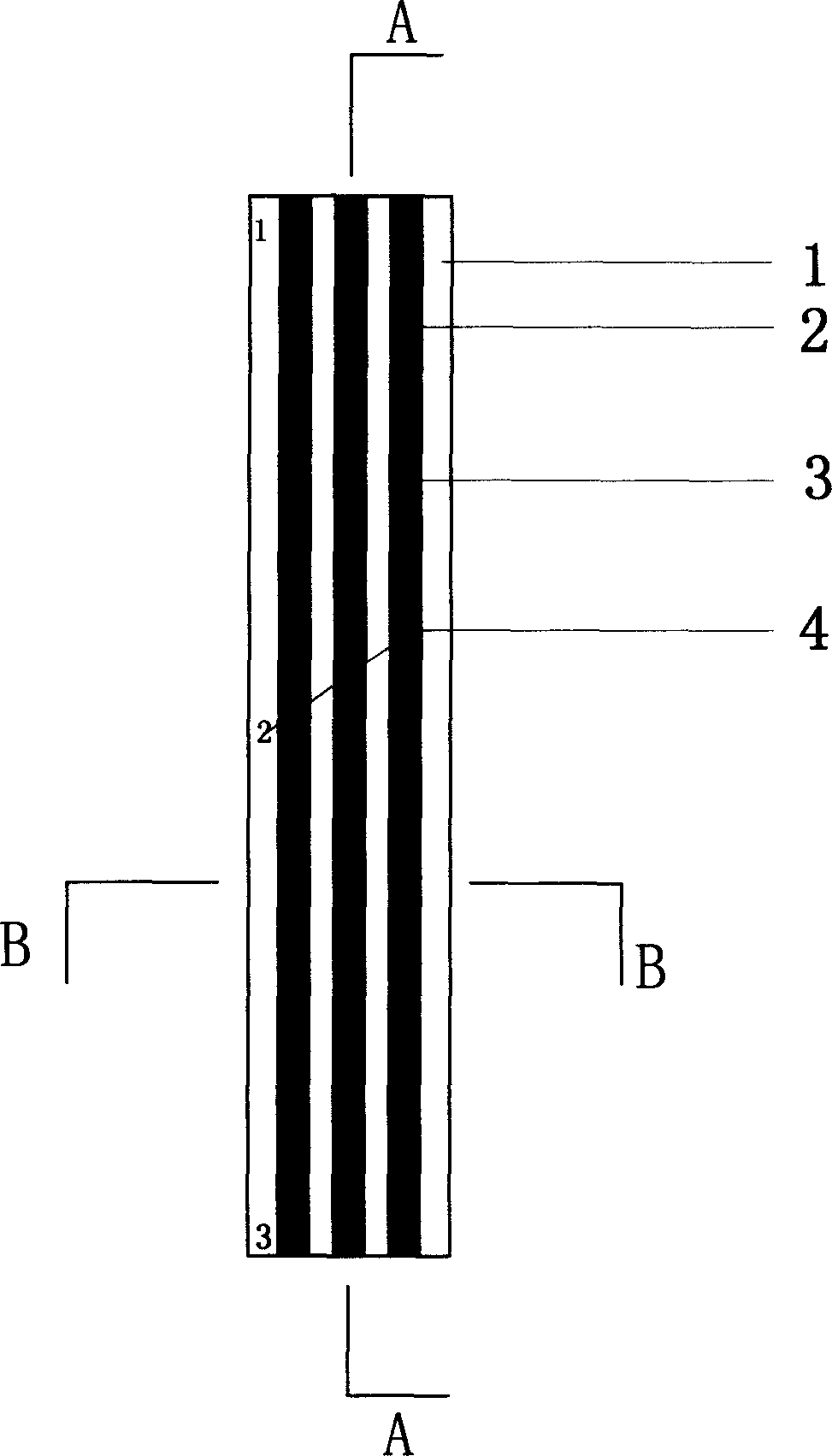

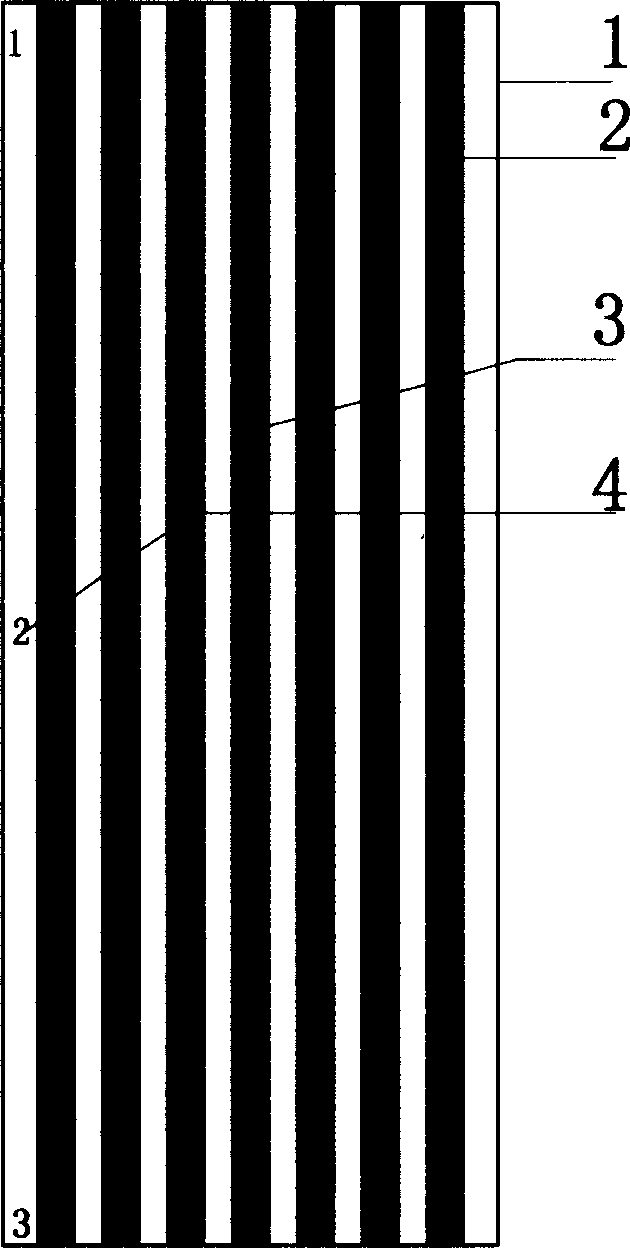

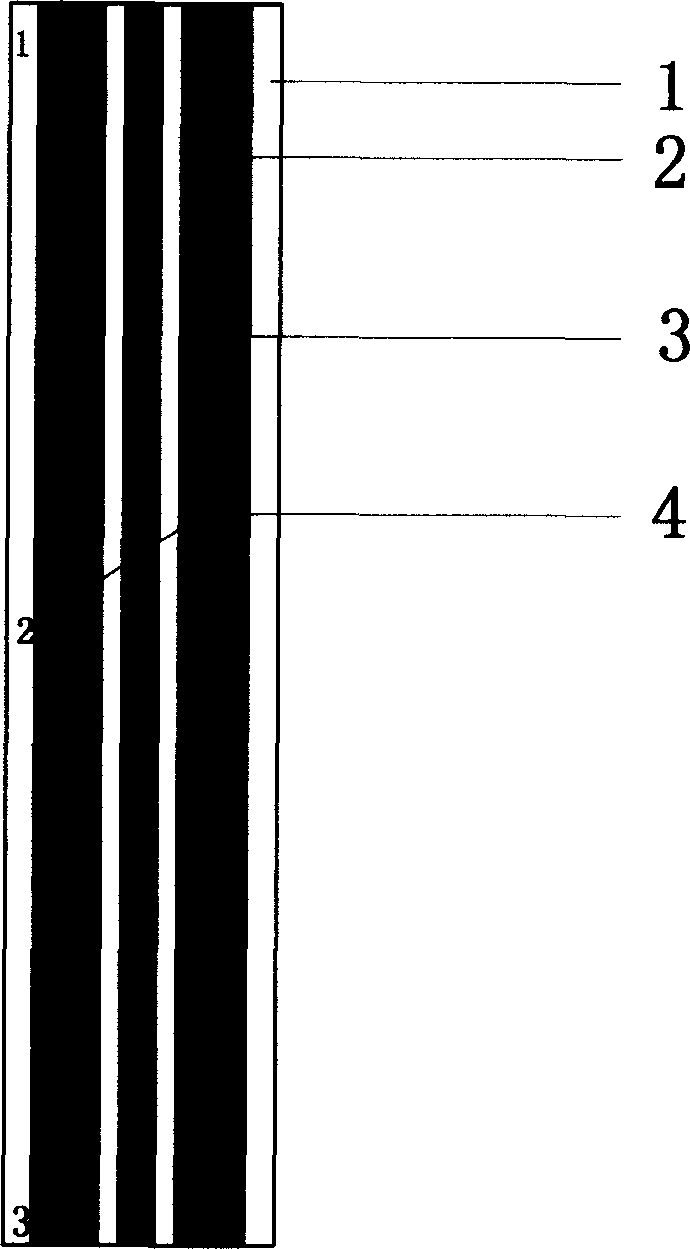

The invented conducting wire possesses composite film 1, metal foil wire 2, and outer layer including pressure-sensitive adhesive layer 5, film 1, inner pressure-sensitive adhesive layer 6, insulating varnish layer 7, metal foil wire 2 and film 1 in sequence. Metal foil wire 2 includes multiple composite structures: bilayered, multilayered composite structures, unequal widths, un-equidistant, symmetrical bilayered and multilayered, unsymmetrical bilayered and multilayered composite structures. The invented metal foil wire is suitable to controlled signal lines, power lines in low voltage and small power providing features of high conductivity, small resistance and easy installation.

Description

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Owner 李广东

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap