Phase transformation heat storage device production method and its products

A technology of phase conversion and heat storage device, which can be applied to electric heating devices, ohmic resistance heating, heating devices for treatment and other directions, and can solve the problems of low popularity and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

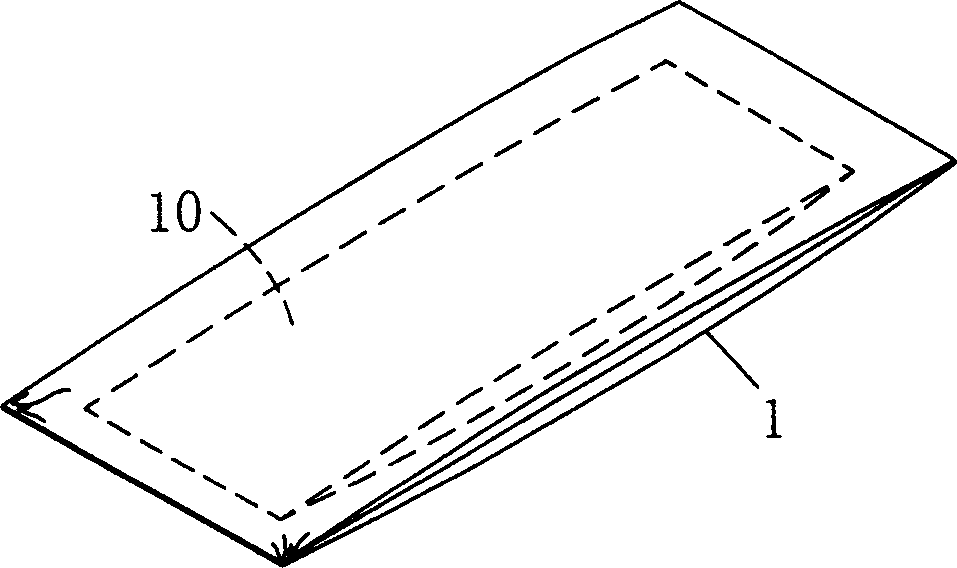

Image

Examples

Embodiment Construction

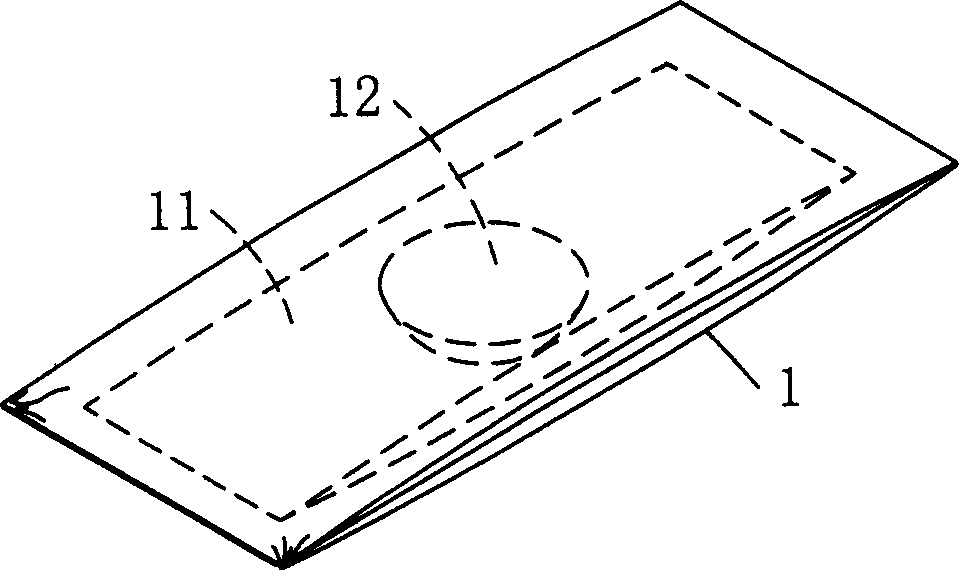

[0024] refer to image 3 , Figure 4 , a preferred embodiment of the manufacturing method of the phase conversion heat storage device of the present invention includes step 1, providing an anti-leakage packaging body 2 with an accommodating space 20 inside. In this embodiment, the anti-leakage packaging body 2 can be made of PE It is made of (polyethylene) material or aluminum foil material, which is not easy to leak, not easy to break and durable, and a positioning device 3 is provided in the space 20 in the anti-leakage packaging body 2. In this embodiment, the positioning The device 3 is four belts 30 and is respectively positioned on the four corners 21 of the accommodation space 20 to be suspended in the accommodation space 20; step 2, by means of the positioning device 3, a heat storage device 4 is positioned, the The heat accumulator 4 is covered with a heating element 41 on a metal sheet 40, wherein the heating element 41 is a wire loop 410 wound in a regular circle. The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap