System for detecting film quality variation and method using the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

[0019] Reference will now be made in detail to exemplary embodiments of the present invention, examples of which are illustrated in the accompanying drawings. Wherever possible, like reference designations will be used throughout the drawings to refer to the same or similar parts.

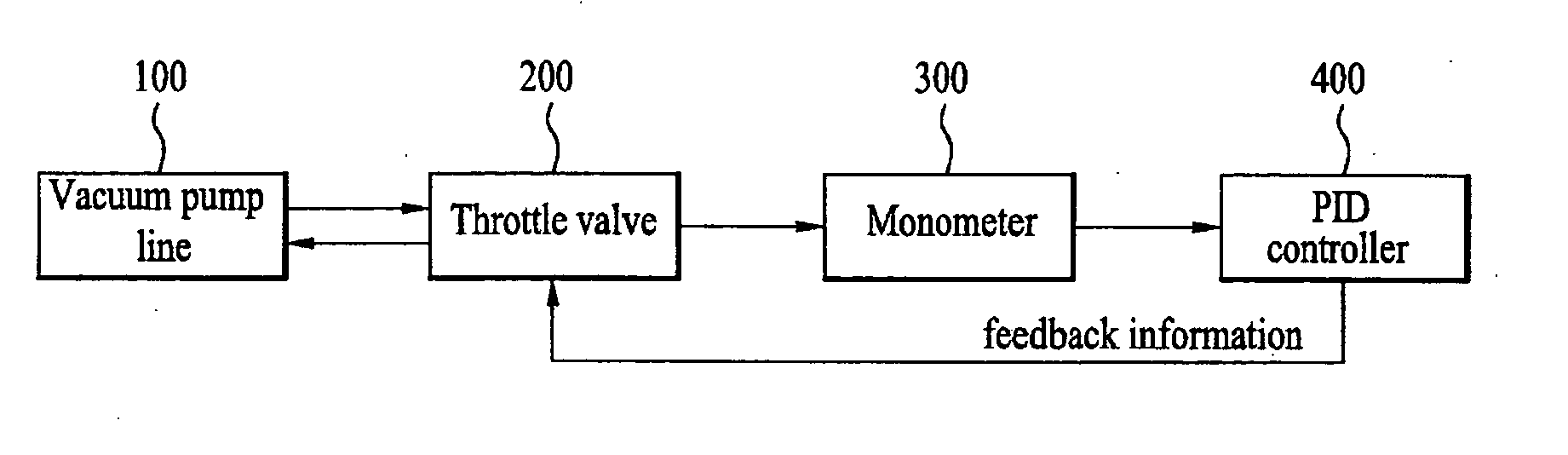

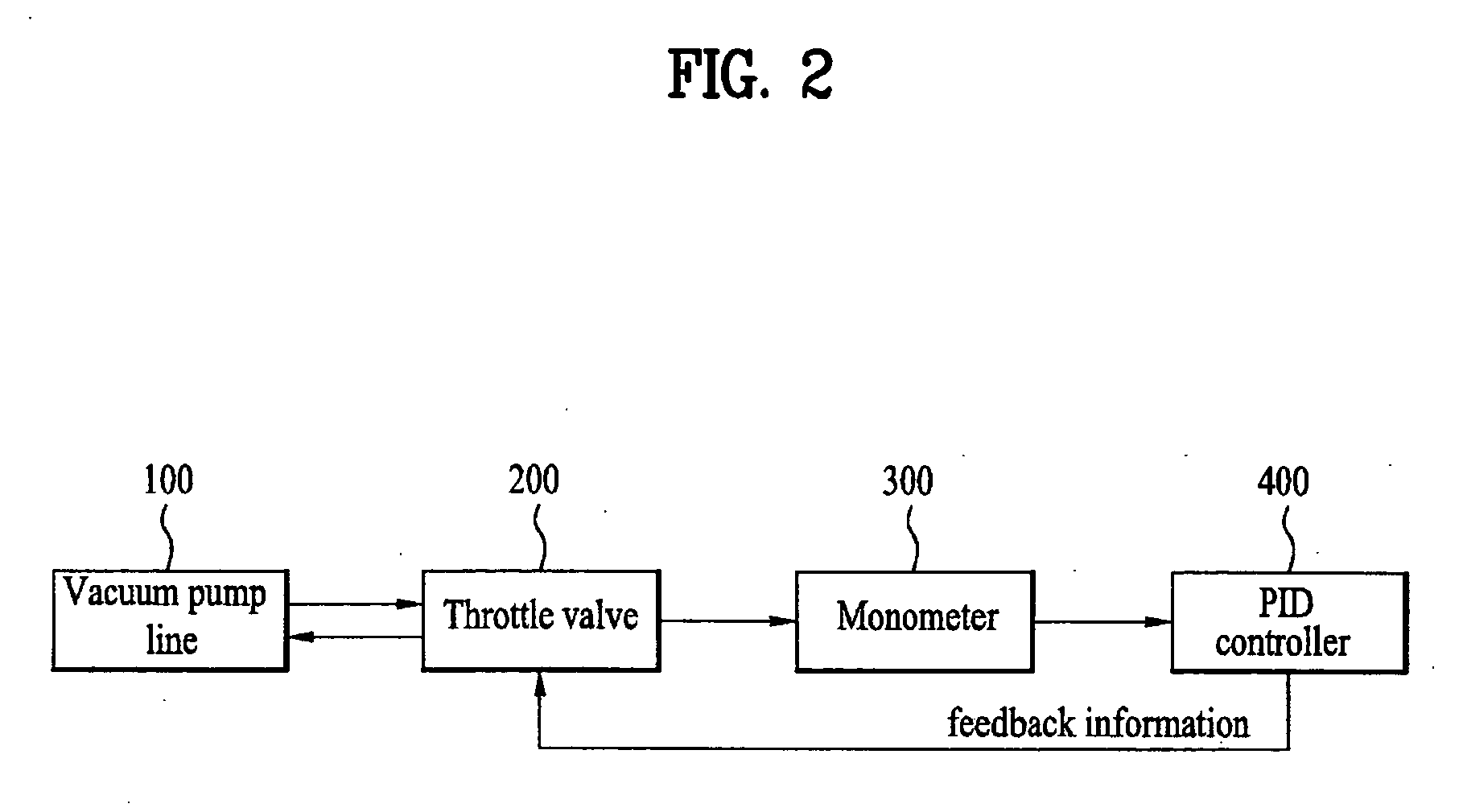

[0020] Referring to FIG. 2, illustrating a system for detecting film quality variation according to one embodiment of the present invention, a vacuum pump line 100 generates pressure during dry etching. A throttle valve 200 moves in response to the pressure of the vacuum pump line 100 and controls the pressure of the vacuum pump line 100. A monometer 300 measures the movement of the throttle valve 200 and outputs movement data indicative of the movement of the throttle valve to a proportional integral derivative (PID) controller 400. The PID controller 400 outputs the feedback information to the throttle valve 200. the throttle valve 200 controls the pressure of the vacuum pump line 100 based on the feedback

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field | aaaaa | aaaaa |

| Pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap