Carriage and gantry comprising such a carriage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

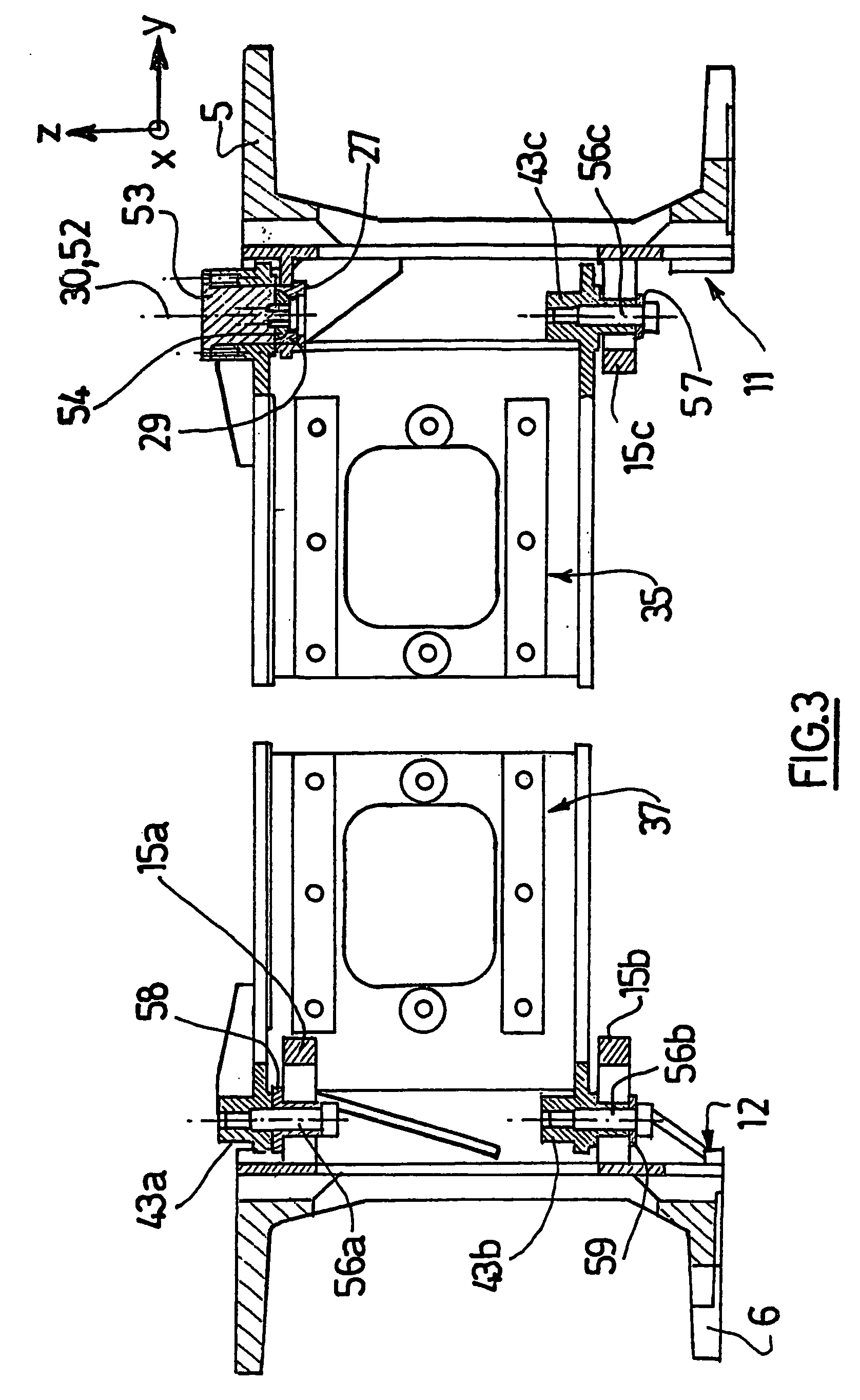

[0026] Reference is made first of all to FIG. 1, which depicts a quadratic gantry 1 comprising first and second lateral girders 2, 3 substantially parallel to each other. The girders can have a length attaining 20 to 30 m, and be spaced apart by 5 to 10 m for example. The direction x of the lateral girders 2, 3 is said to be longitudinal, and the orthogonal direction y situated in the plane of the girders is said to be transverse. A third direction z, orthogonal to the other two, is also defined. The direction z is said to be vertical. However, this term is employed only for the purpose of simplification of the description, since the plane formed by the lateral girders 2, 3 may be not horizontal but inclined. A location close to the longitudinal axis situated halfway between the two lateral girders 2, 3 is said to be “internal”, in contradistinction to a location at a distance from this axis, said to be “external”. The terms “top”, “bottom”, “above”, “below”, “high”, “low” will be empl

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap