Substrate holder for optical coating machines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example

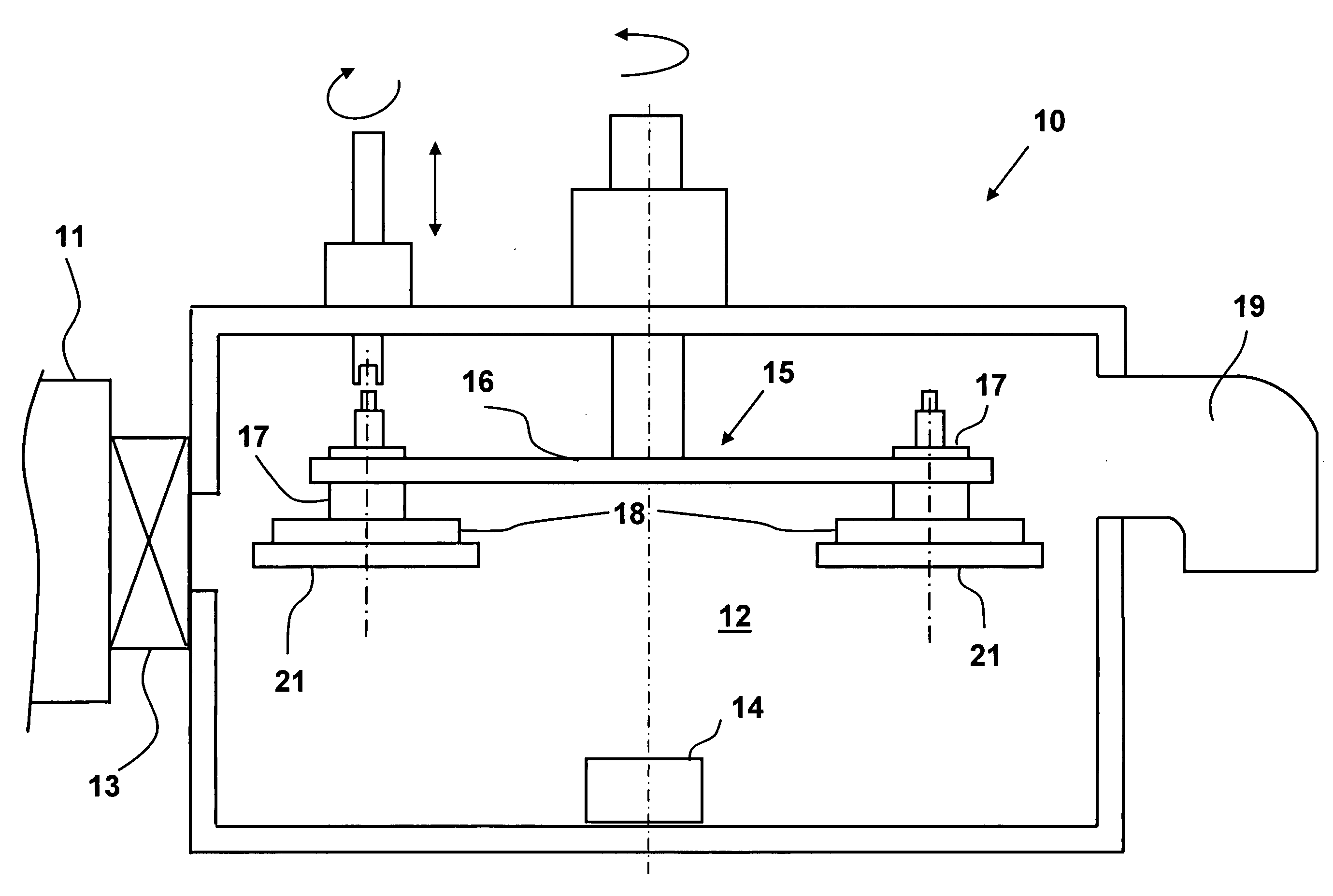

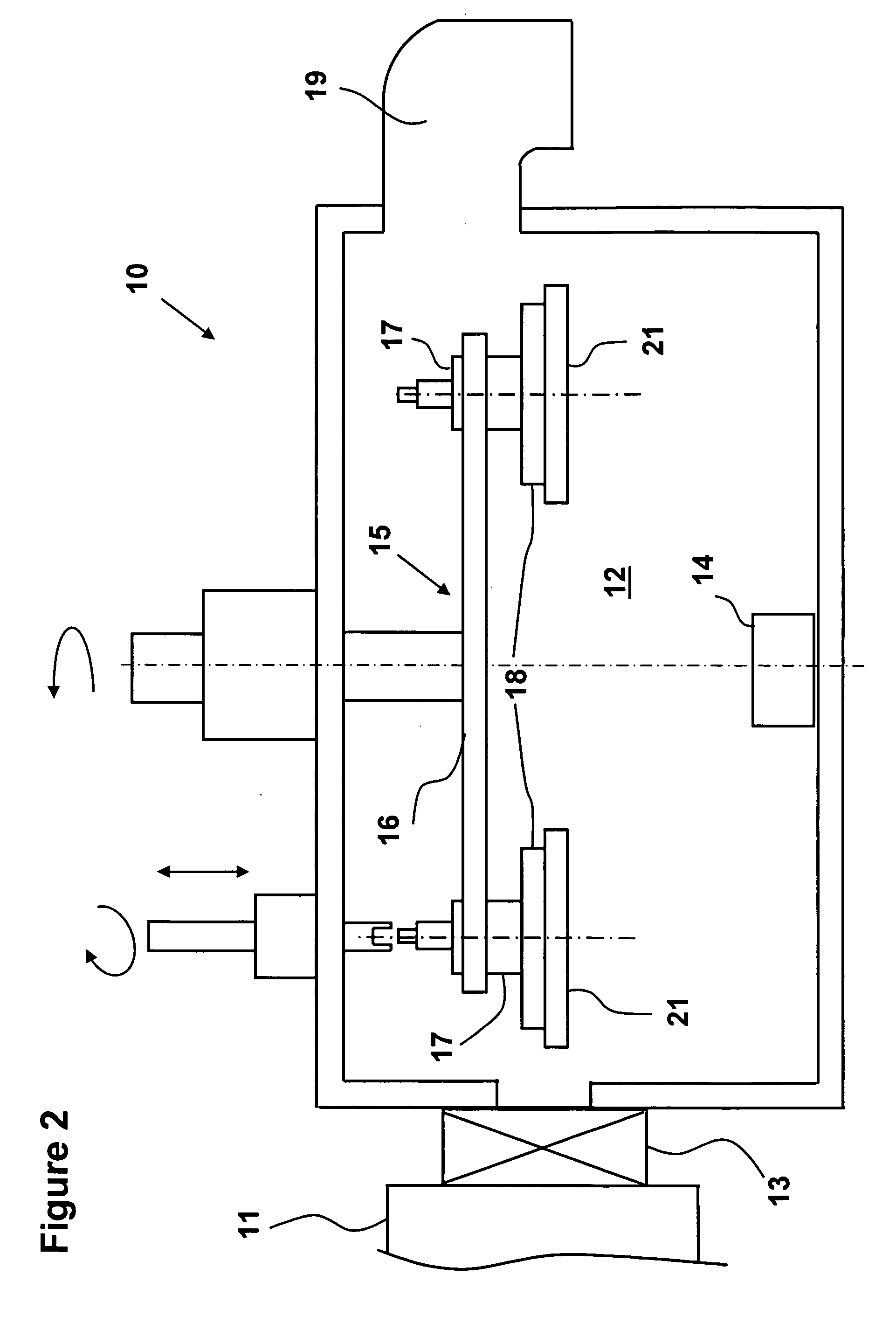

[0015] With reference to FIG. 2, a coating machine 10, e.g. a Physical Vapor Deposition (PVD) or a Chemical Vapor Deposition (CVD) system, for use with the present invention includes a load lock chamber, generally indicated at 11, and a process chamber 12 with a gate valve 13 therebetween. The gate valve 13 enables the pressure in the load lock chamber 11 to be brought to atmospheric pressure for loading and unloading of substrates or to be re-established to the pressure of the process chamber 12 for substrate transfer, independently of the pressure in the process chamber 12. Preferably, the load lock chamber 11 includes a loading container with a cassette elevator therein, and a transfer channel with a robotic arm therein for transferring the substrate holders between the load lock chamber 11 and the process chamber 12.

[0016] A cathode 14, and a planetary substrate support 15 are mounted within the process chamber 2. The planetary substrate support 15 comprises a main cylindrical pla

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexibility | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap