Avoiding temperature-related faults of a laser by temperature adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

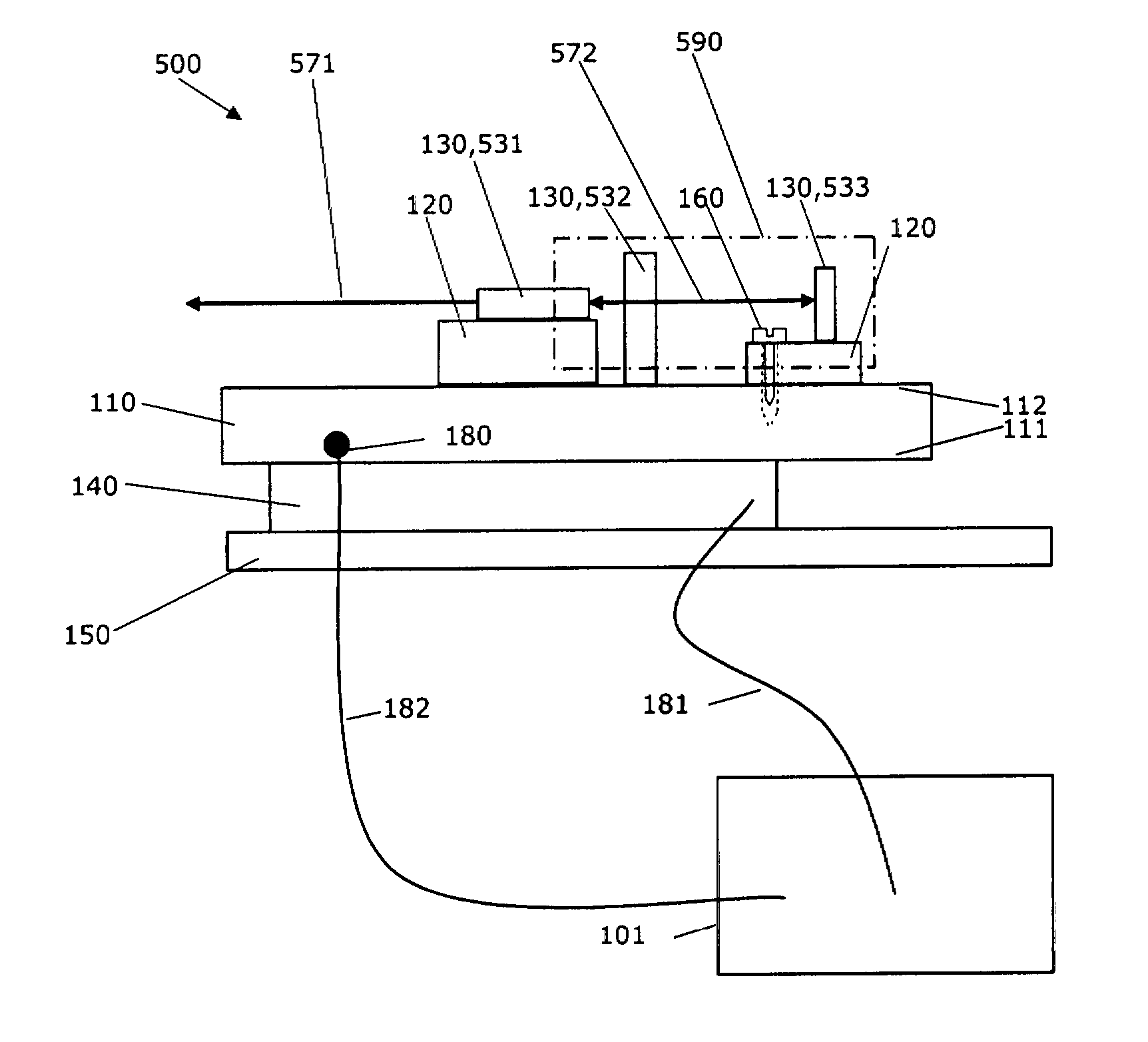

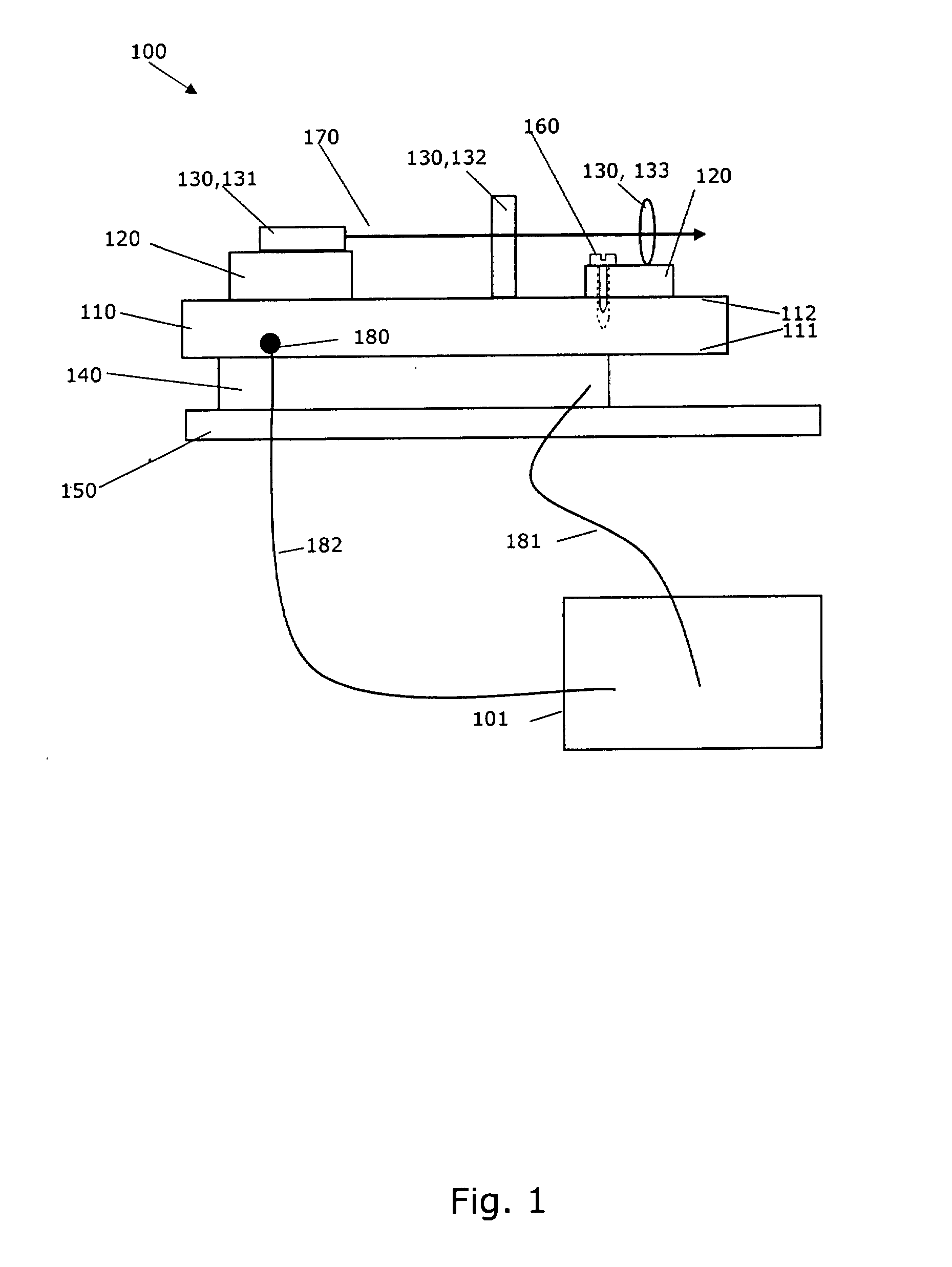

[0054]FIG. 1 is a principal sketch of a laser system comprising a semiconductor laser 100 and a temperature control system 101.

[0055] The semiconductor laser 100 comprises optical components 130 for instance semiconductor laser diodes, optical filters, gratings, mirrors, wave plates, lenses, frequency doubling crystals and electro-optic components. In FIG. 1, the semiconductor laser device is illustrated as comprising a semiconductor laser diode 131 which generates a beam 132 that is transmitted through an optical filter 132 and beam shaping optics 133. It should be understood that the semiconductor laser device 100 may contain other optical components, and that the semiconductor laser 100 can be of different types, including but not limited to: external cavity lasers, frequency doubled lasers, pumped lasers, pulsed lasers and semiconductor lasers comprising only a laser diode and beam shaping optics. Similarly, the semiconductor laser diode 131 can be of various types, including but

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap