Oven protection system for a thermo-forming machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

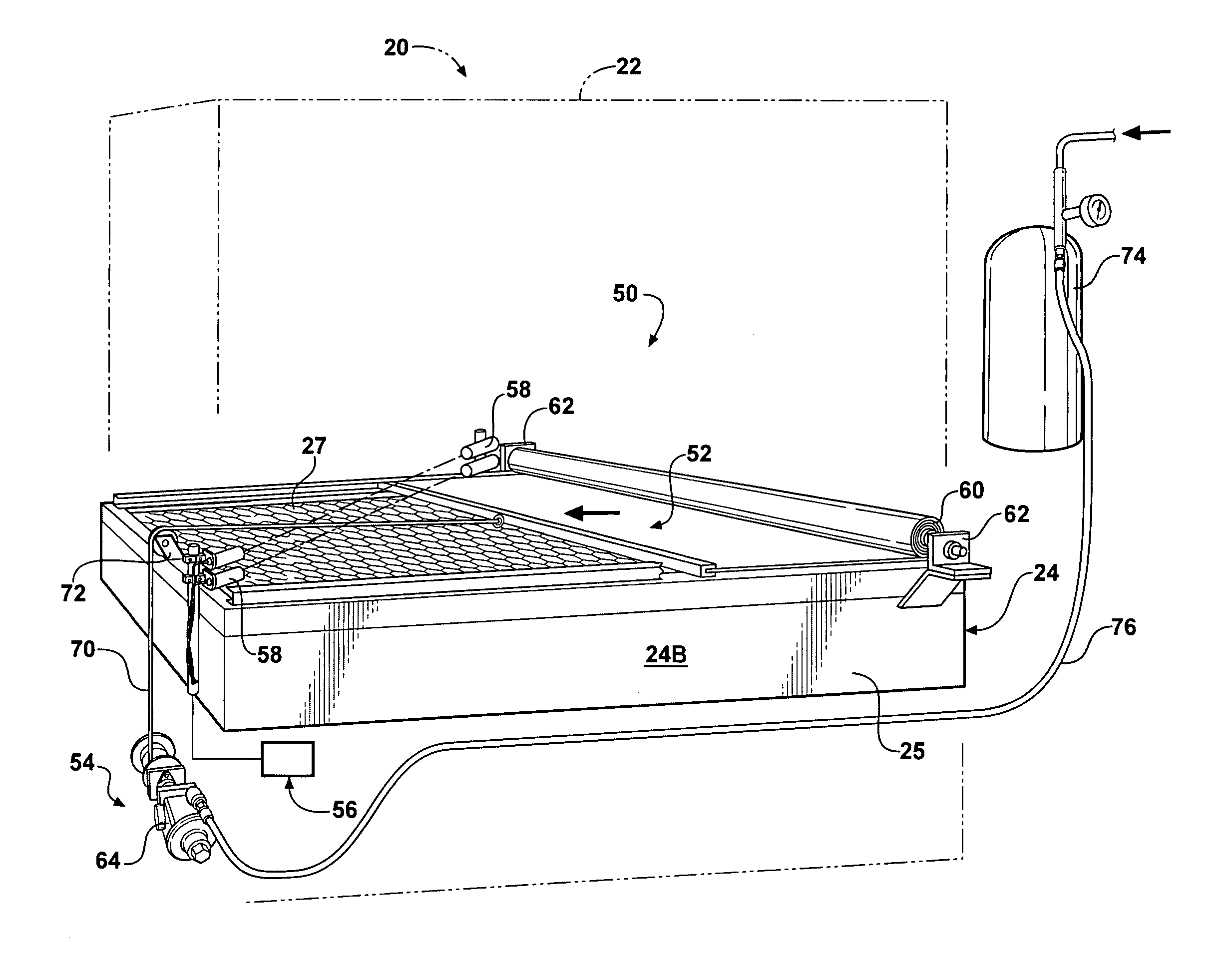

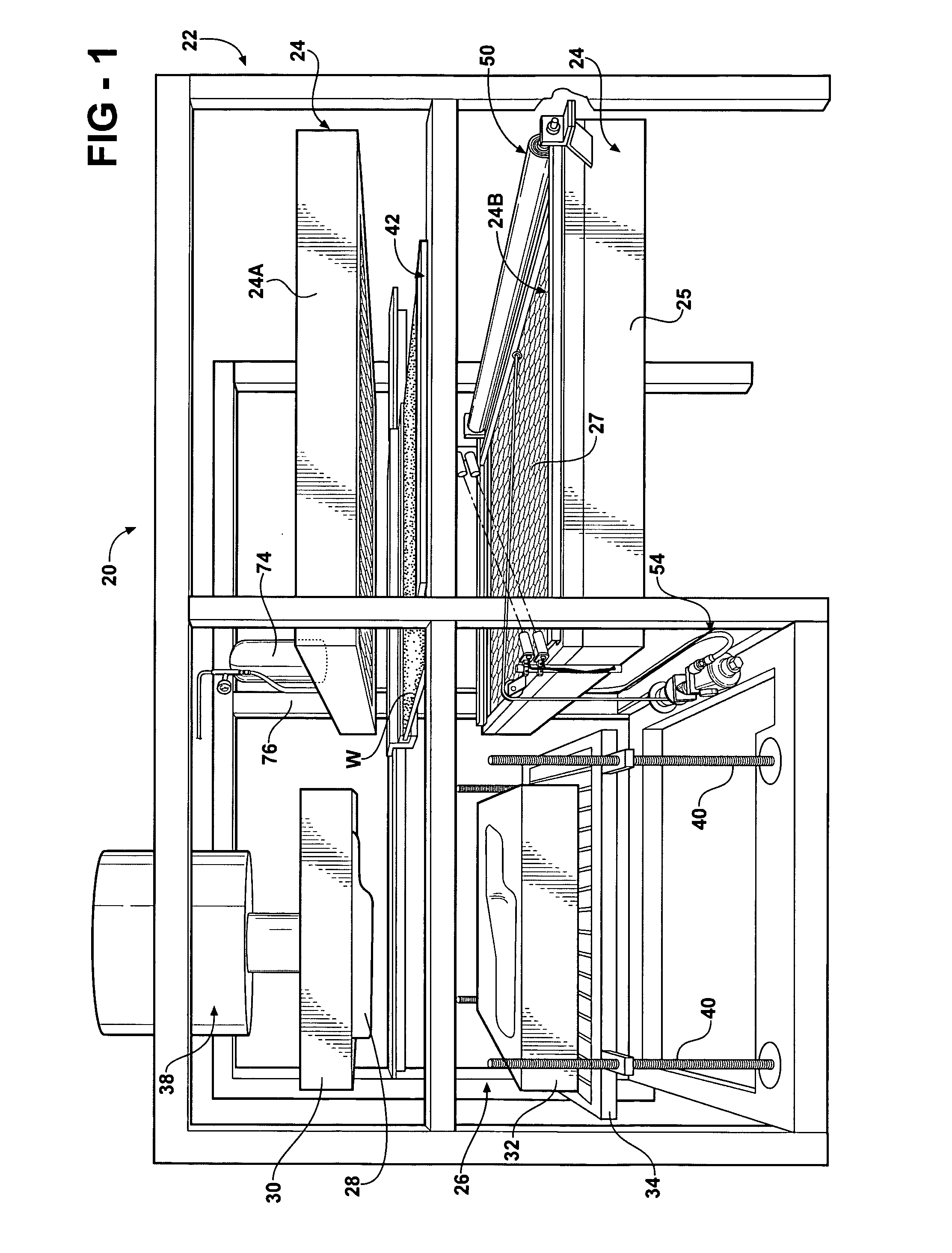

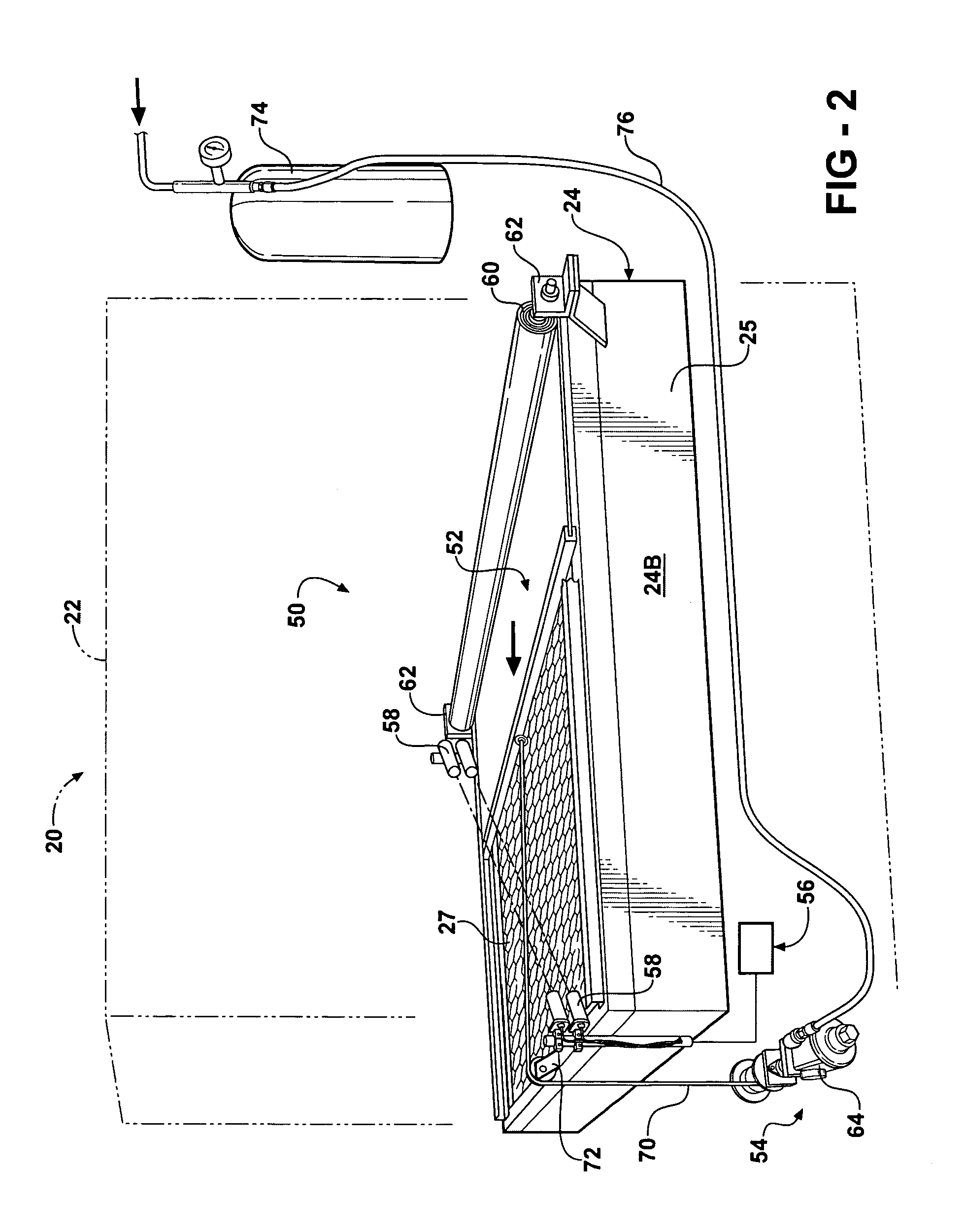

[0020]One representative example of a thermo-forming machine is generally indicated at 20 in FIG. 1. The thermo-forming machine 20 illustrated in this figure is conventional in many respects in that it includes a main superstructure, generally indicated at 22, which supports a source of heat, such as a convection or infrared oven, generally indicated at 24, and a mold assembly, generally indicated at 26. Thus, the oven may be gas-fired, electric or may use any other suitable source of heat of the type commonly known in the related art. In the representative example illustrated in FIG. 1, the oven 24 may include upper and lower sections 24A, 24B, respectively, that are employed to heat and ultimately plasticize the workpiece W. Each upper and lower sections 24A and 24B include a housing 25 in which is supported a plurality of heating elements. A screen 27 forms the upper portion of the lower oven section 24B. The thermo-forming machine 20 illustrated in FIG. 1 has a double-ended, shutt

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap