Systems and methods for electrical leakage detection

a leakage detection and detection system technology, applied in the direction of emergency protective arrangements for limiting excess voltage/current, instruments, electric devices, etc., can solve the problem of not addressing the detection of electrical leakage in a balanced fault condition, the fatigue or failure of a conductor's insulation of a machine component, and the leakage of electrical current from a high-voltage power supply to a machine fram

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

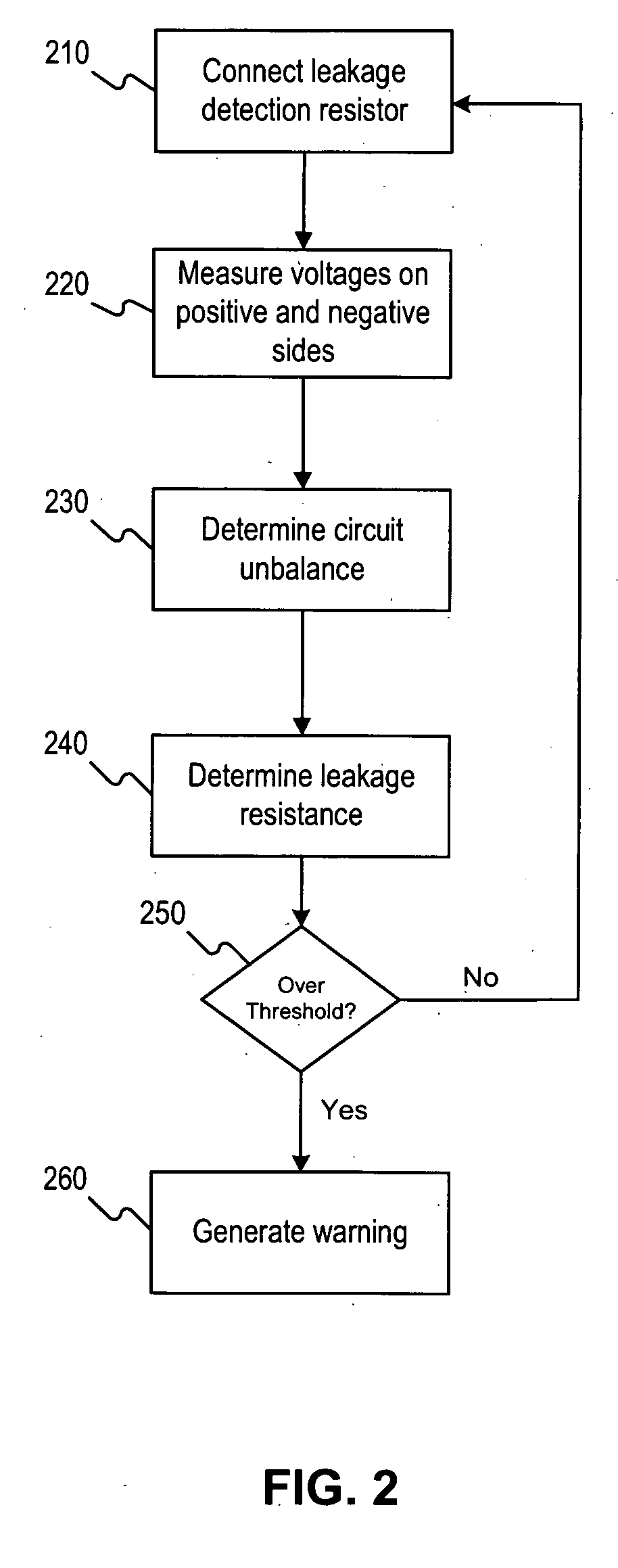

[0011]Reference will now be made in detail to the disclosed embodiments, examples of which are illustrated in the accompanying drawing. Wherever possible, the same reference numbers will be used in the drawing to refer to the same or like parts.

[0012]In the disclosed embodiments, a machine may refer to a petroleum-electric hybrid powered machine, such as a hybrid-electric vehicle which uses internal combustion engines and electric batteries, fuel cell, or other electrical power source to power electric motors. A machine may also refer to a machine with one or more electric motors and an electric power source such as an electric vehicle.

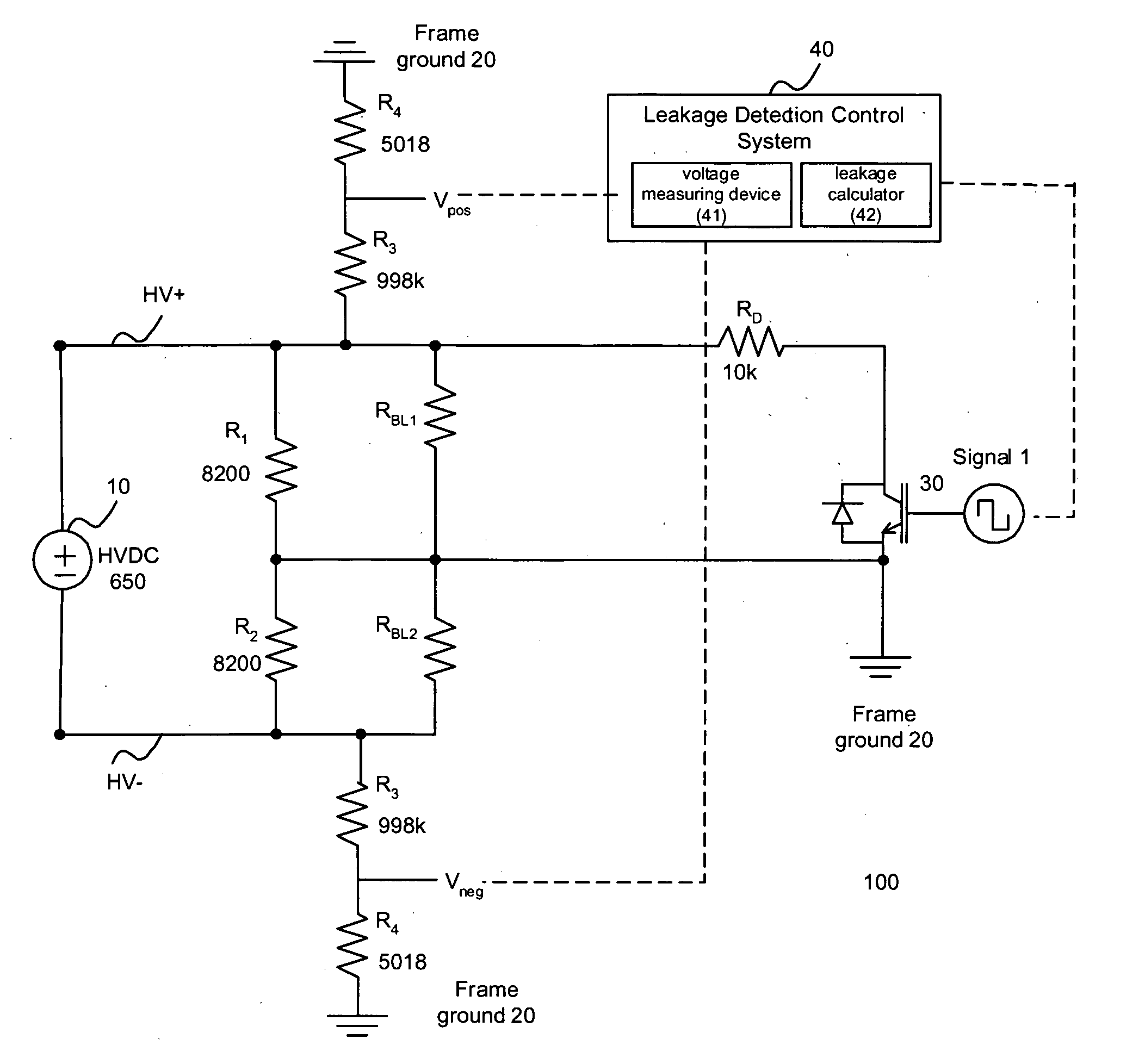

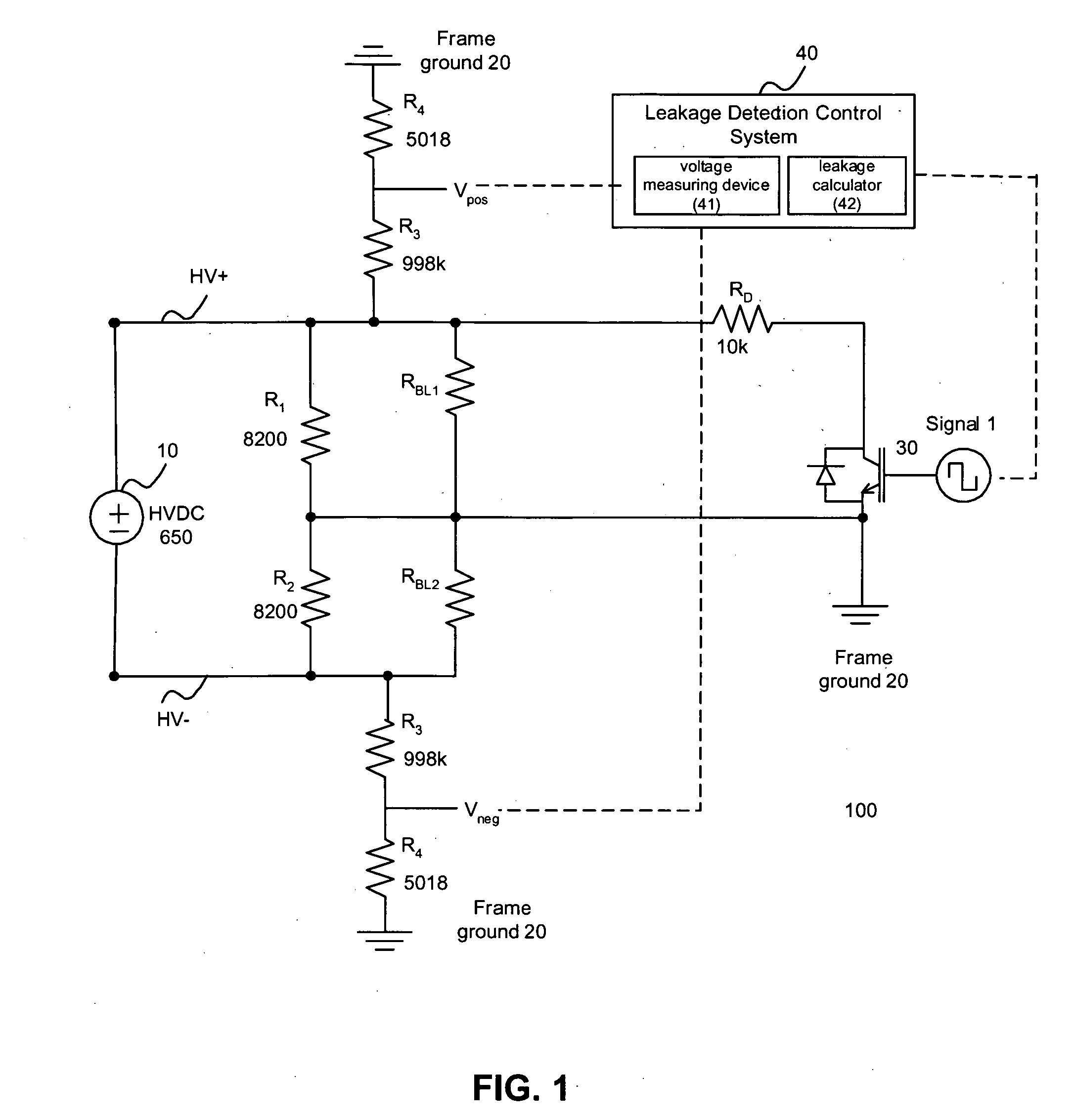

[0013]FIG. 1 illustrates an electrical leakage detection circuit 100 consistent with the disclosed embodiments. Electrical leakage detection circuit 100 may be used to detect the presence of an electrical leakage current between a terminal of a high voltage DC power supply and the frame of a machine. In one embodiment, a “frame” may refer to the conducti

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap