Anti-Static Sole

a technology of anti-static soles and soles, applied in the field of shoes, can solve the problems of high cost, high static charge on the user, and damage to precision equipment such as electronic elements or magnetic memory cards, so as to avoid the damage of resistors, reduce static charge, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]The present invention will be clearer from the following description when viewed together with the accompanying drawings, which show, for purpose of illustrations only, the preferred embodiment in accordance with the present invention.

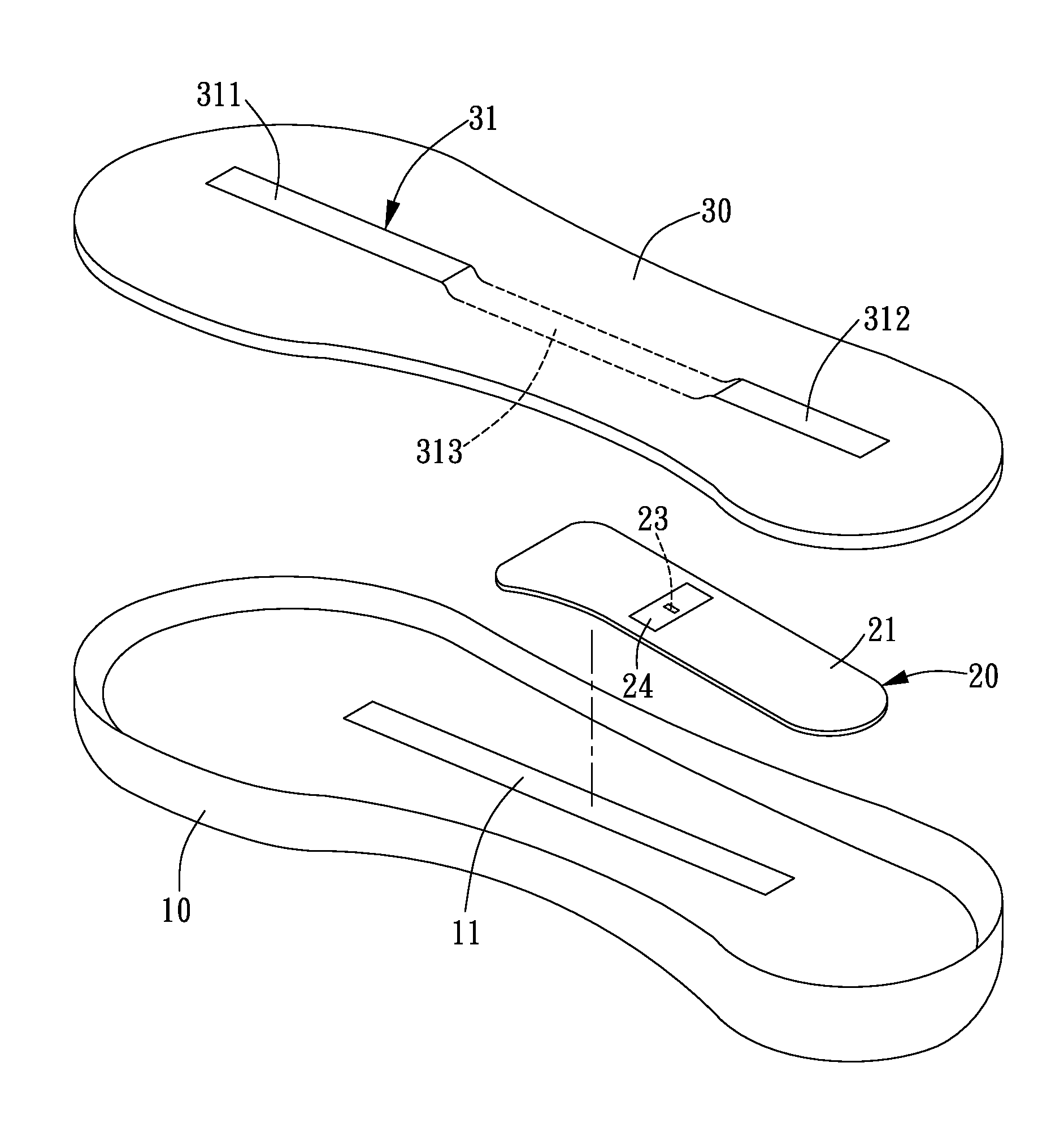

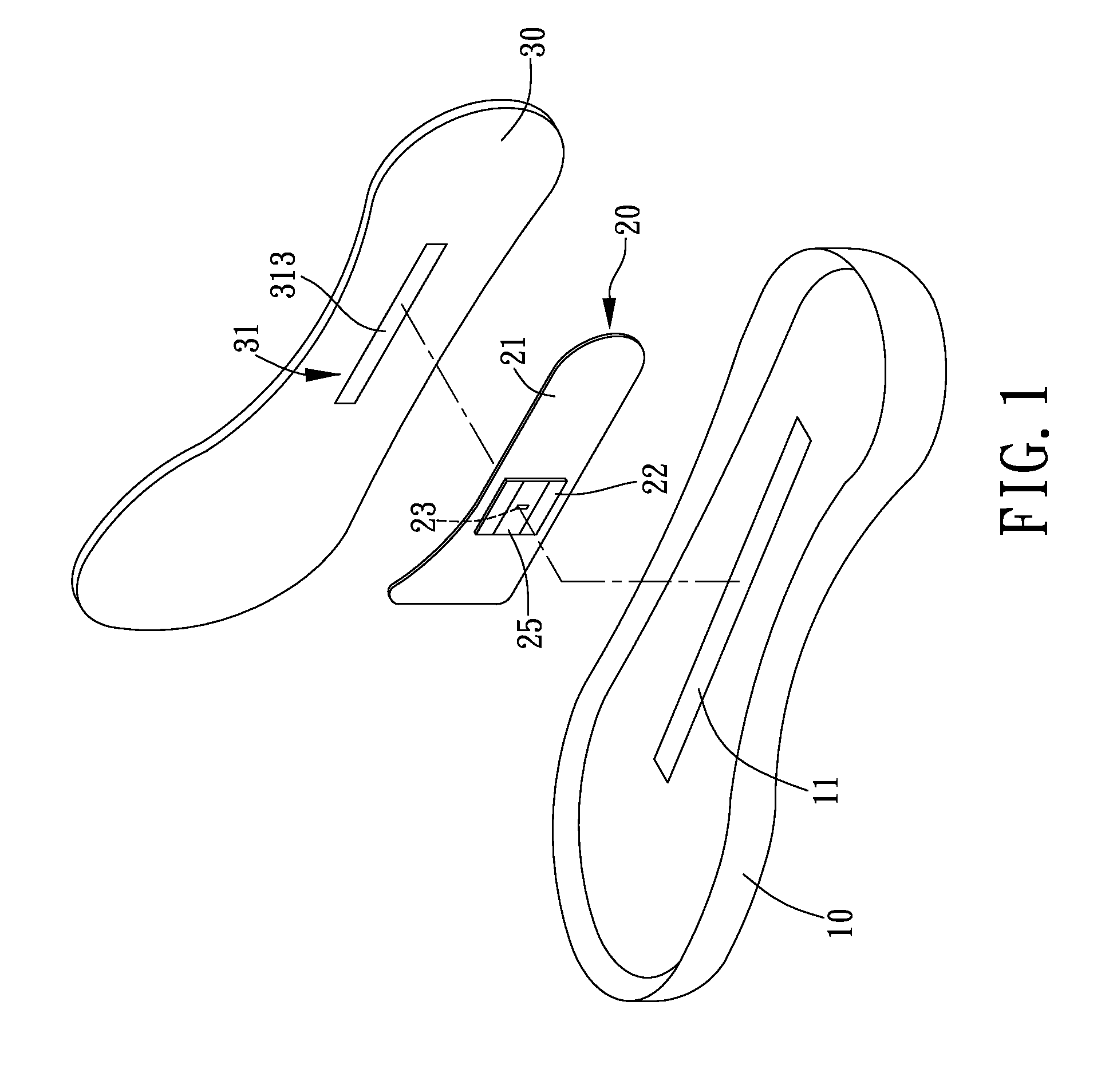

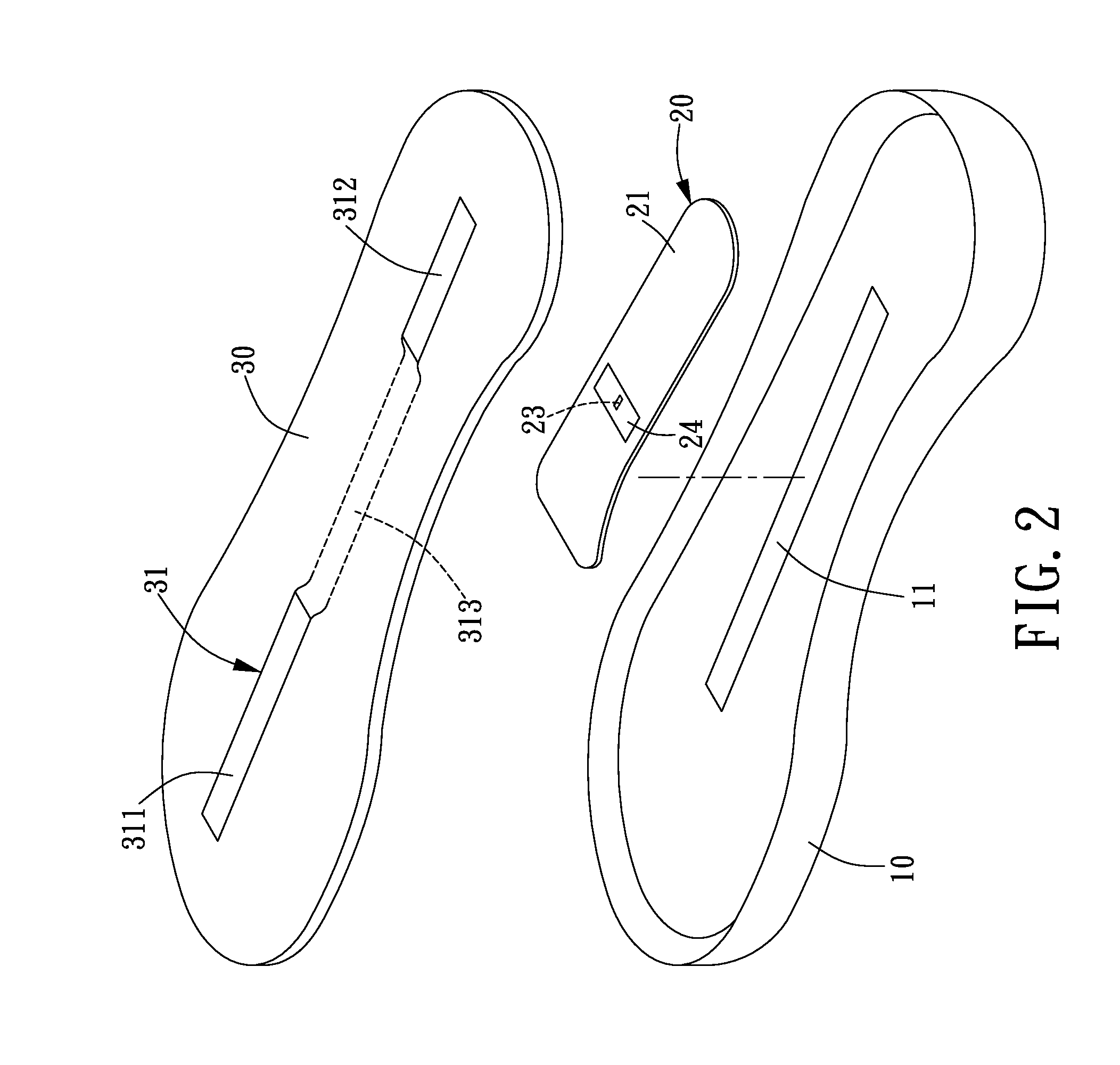

[0024]Referring to FIGS. 1-4, an anti-static sole in accordance with the present invention comprises a midsole 10, a pad body 20, and an insole 30.

[0025]The midsole 10 is made of conductive material and provided with a first conductive element 11. The first conductive element 11 is made of conductive fabric formed by mixed weaving of fiber and wires, so the wires can be used to conduct electricity. The first conductive element 11 is exposed from a top surface of the midsole 10.

[0026]The pad body 20 has a bottom surface disposed at the top surface of the midsole 10. The pad body 20, as shown in FIG. 3a, includes a main pad 21, an assistant pad 22, a chip resistor 23, an upper conductive fabric 24 and a lower conductive fabric 25. The main pad 21 incl

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap