Fastening Unit for Ignition Units and Device for Carbon Deposition

a technology of fastening unit and ignition unit, which is applied in the direction of vacuum evaporation coating, plasma technique, gas-filled discharge tube, etc., can solve the problems of low deposition rate, difficult control of dc arc vaporization of carbon, and inconvenient economic use of methods, etc., to achieve simple exchange of ignition unit and rapid exchanging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

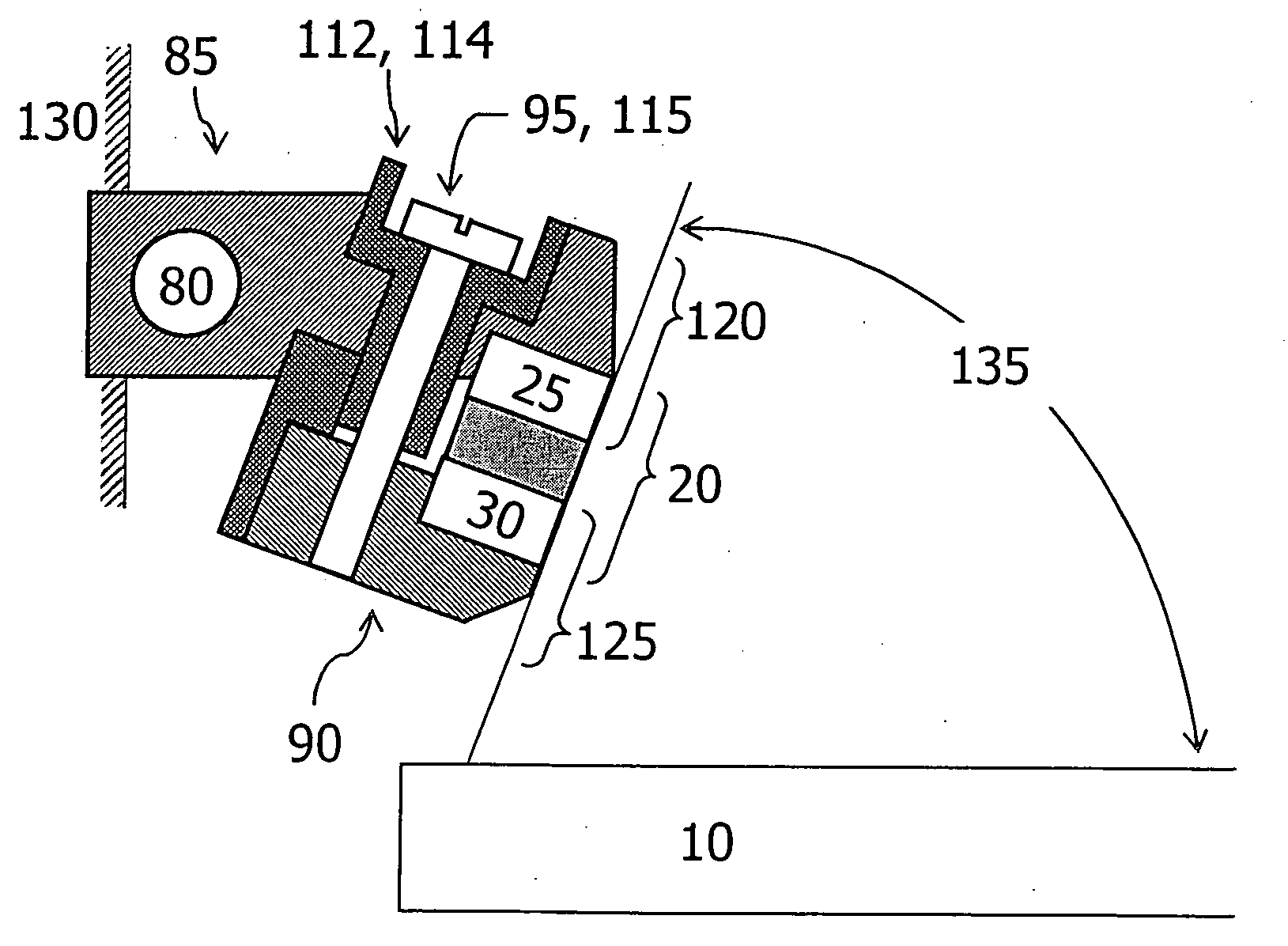

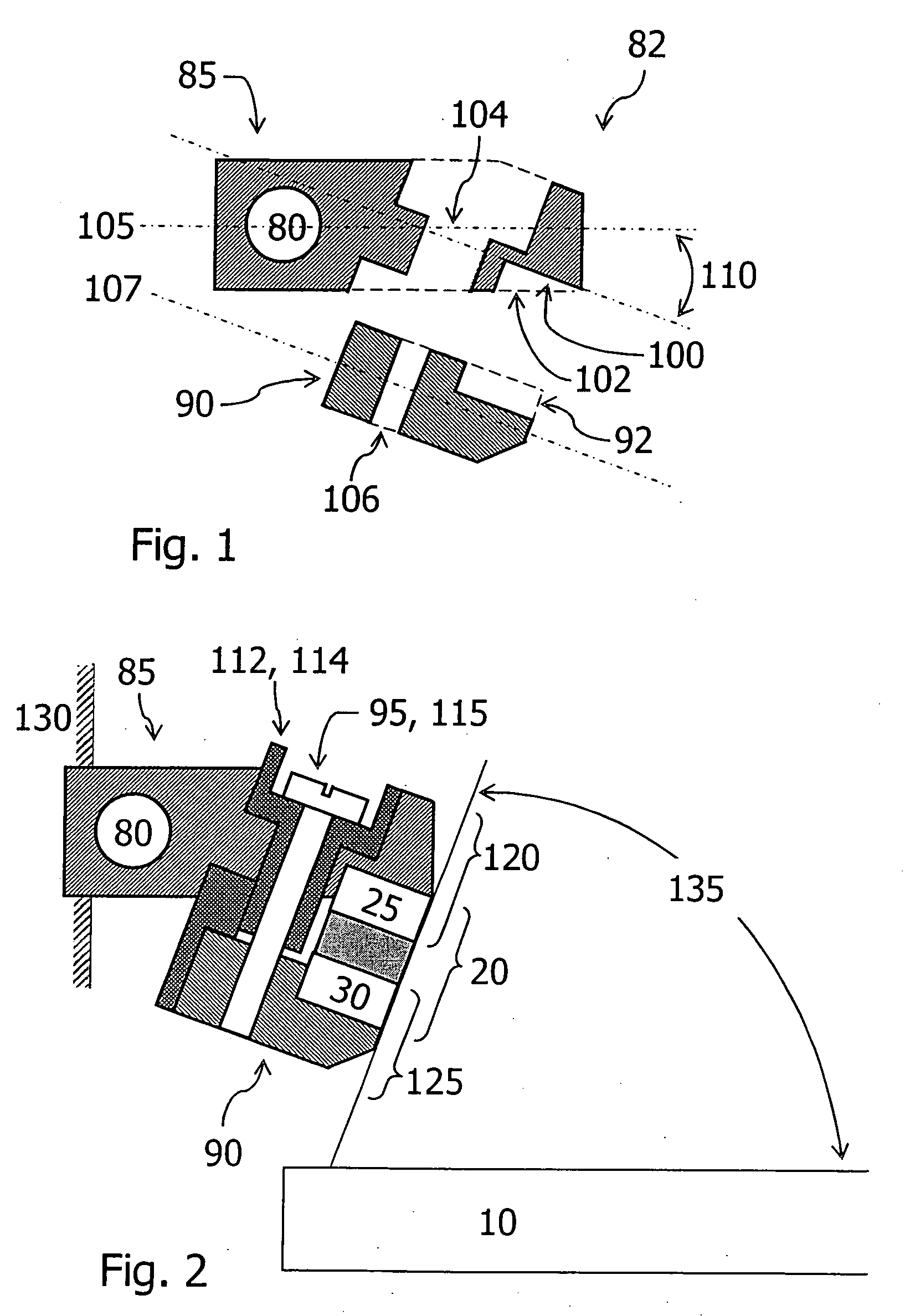

[0019]The fastening unit 82 shown in cross-section in FIG. 1 for an ignition unit, in particular of a carbon deposition device, has a first and second holder 85, 90. The two holders 85, 90 are held together by a fastening device 95, as is shown in FIG. 2. For both holders 85, 90, the length extension is greater than the thickness extension. As is shown in FIG. 1, the respective longitudinal axes 105, 107 run along the longitudinal extension of each holder 85, 90. The absolute length of first holder 85 is typically greater than that of second holder 90.

[0020]First holder 85 has a first bore 104 that runs continuously through the thickness of holder 85. Bore 104 is stepped, and has a center section having a smaller diameter. Bore 104 runs at an incline to the surface of holder 85 or to longitudinal axis 105. In addition, at an end area in the longitudinal extension of holder 85 a recess 102 is formed and is open toward second holder 90. Here, recess 102 has a shape such that recess 102 f

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap