System for attenuating pulsation in the gas discharge of a refrigeration compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

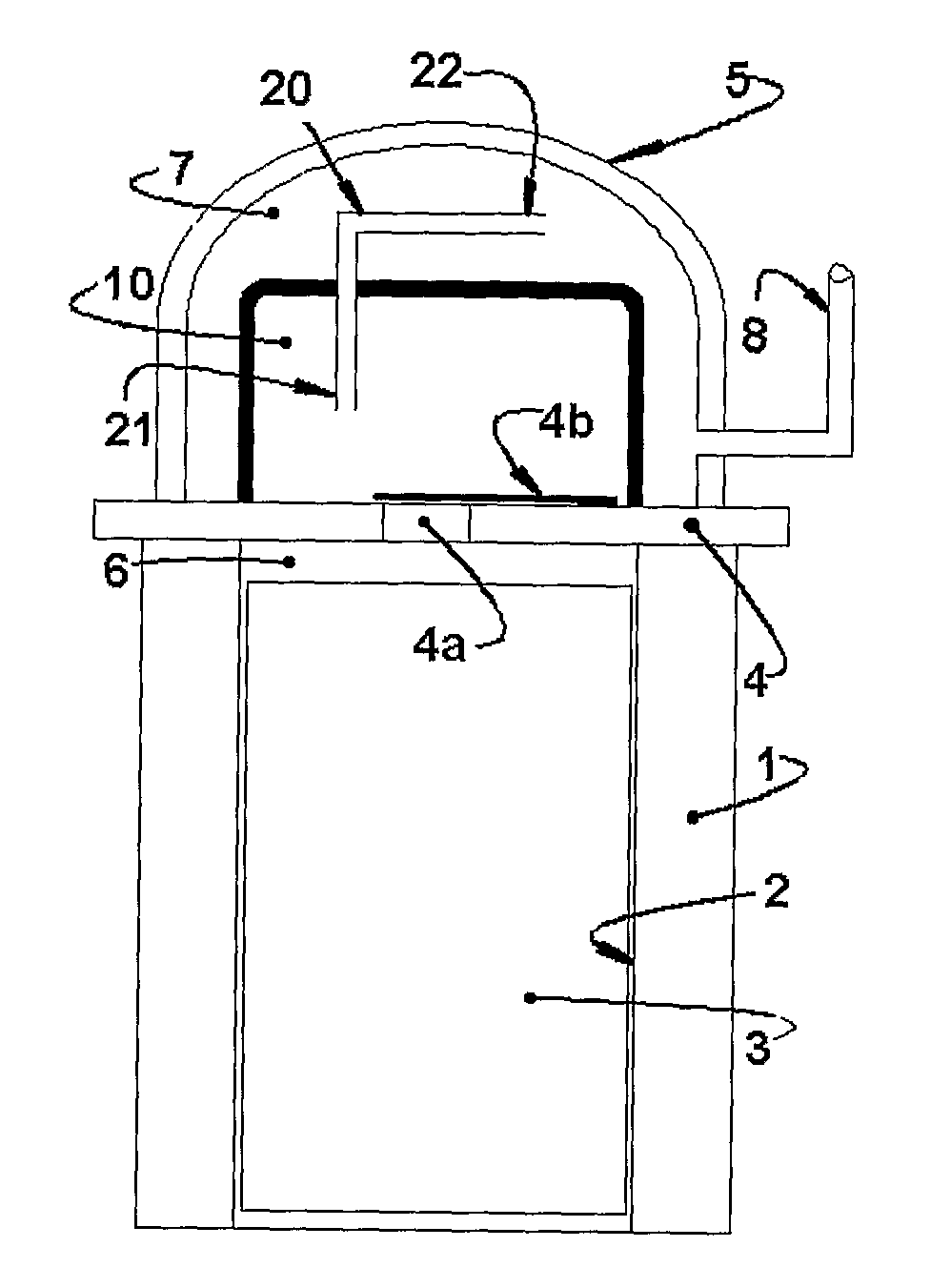

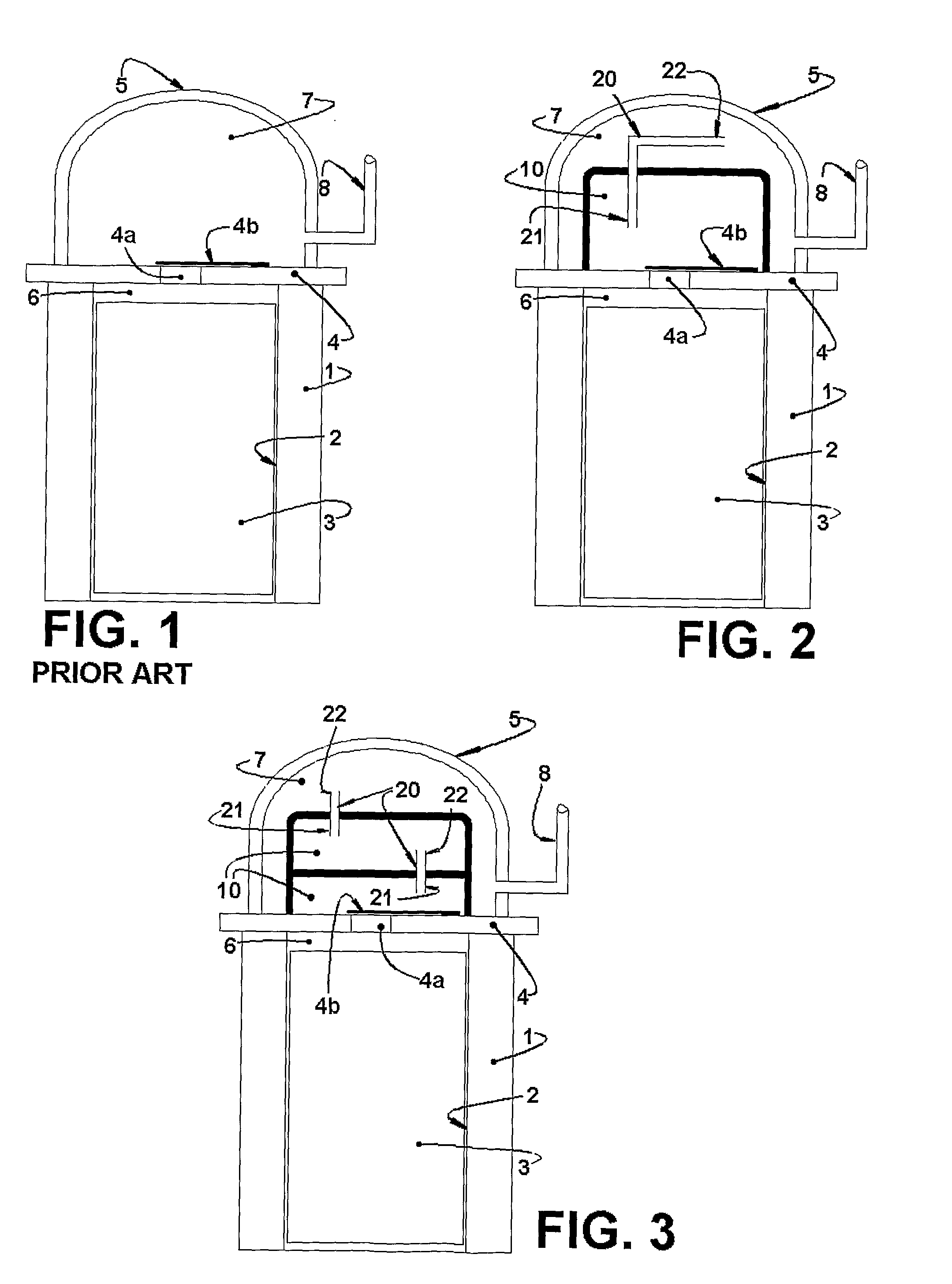

[0015]The present invention will be described for a reciprocating hermetic compressor which comprises a motor-compressor assembly having a cylinder block 1, which defines a cylinder 2, inside which a piston 3 is axially displaced by actuation of a motor (not illustrated). In a particular compressor construction of the type driven by a linear motor, the piston 3 is connected to a resonant spring (not illustrated) and axially displaced in the interior of the cylinder 2 by an actuating assembly (not illustrated), which supports a magnetic component (not illustrated) and which is axially driven upon energization of the linear motor.

[0016]The cylinder 2 has an open end, through which the piston 3 is housed, and an opposite end closed by a valve plate 4, against which is seated a cylinder cover 5. The valve plate 4 carries at least one of the suction valve and discharge valve, which regulate the gas inlet and outlet in relation to the interior of the cylinder 2. In the illustrated constructi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap