Vibration damping apparatus, electric actuator driving apparatus and vehicle

a technology of vibration damping and electric actuator, which is applied in the direction of motor/generator/converter stopper, dynamo-electric converter control, instruments, etc., can solve the problems of harmonic generation, affecting the reliability and durability of the system, and affecting the performance of the system, so as to avoid harmonic generation, effectively enhance the reliability and durability, and effectively prevent the collision of the movable elemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050]In the following, a vibration damping apparatus and an electronic actuator driving apparatus of the present embodiment which are applied to a vehicle are described with reference to FIGS. 1 to 10. The present embodiment corresponds to the first aspect of the disclosure and the second aspect of the disclosure.

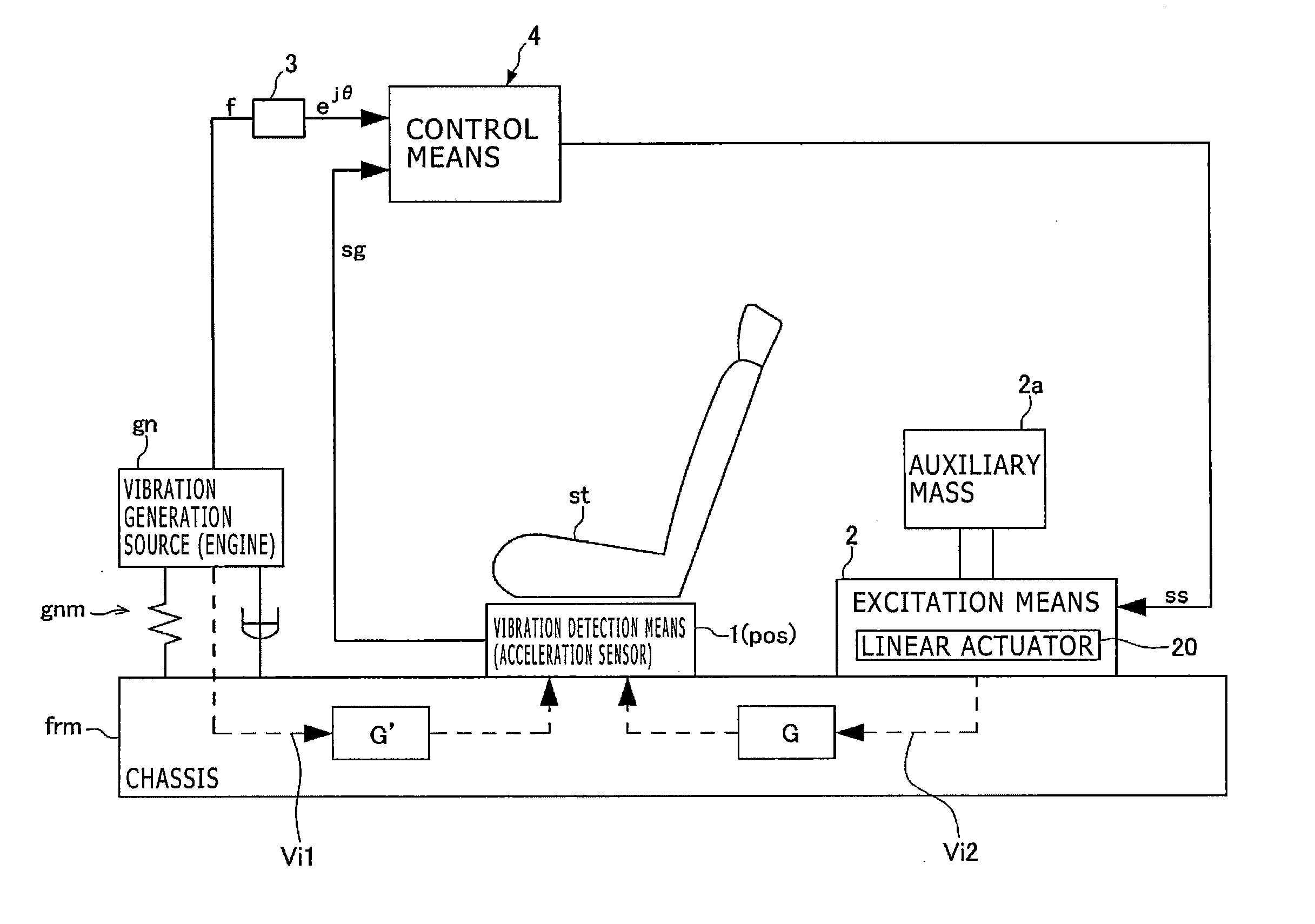

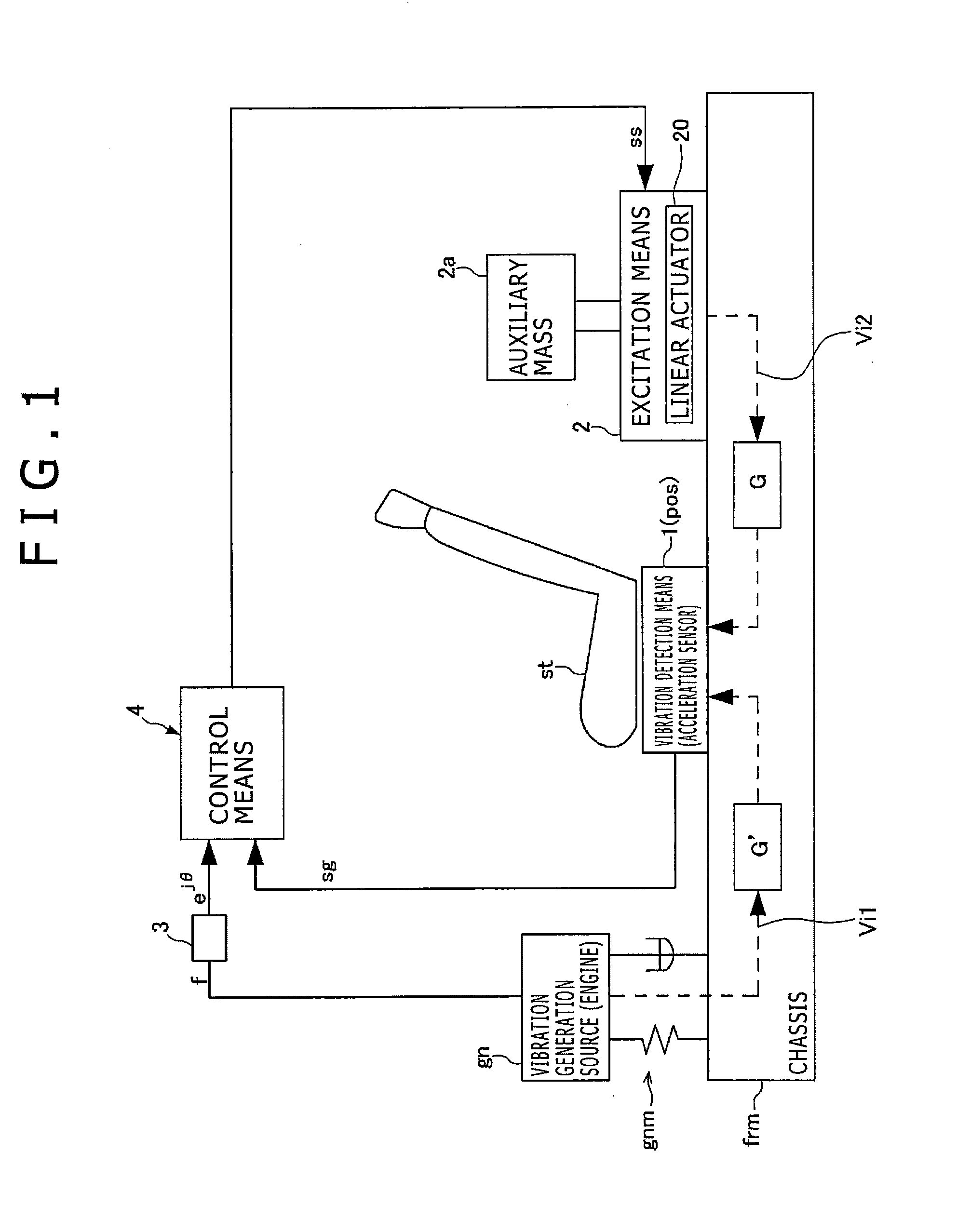

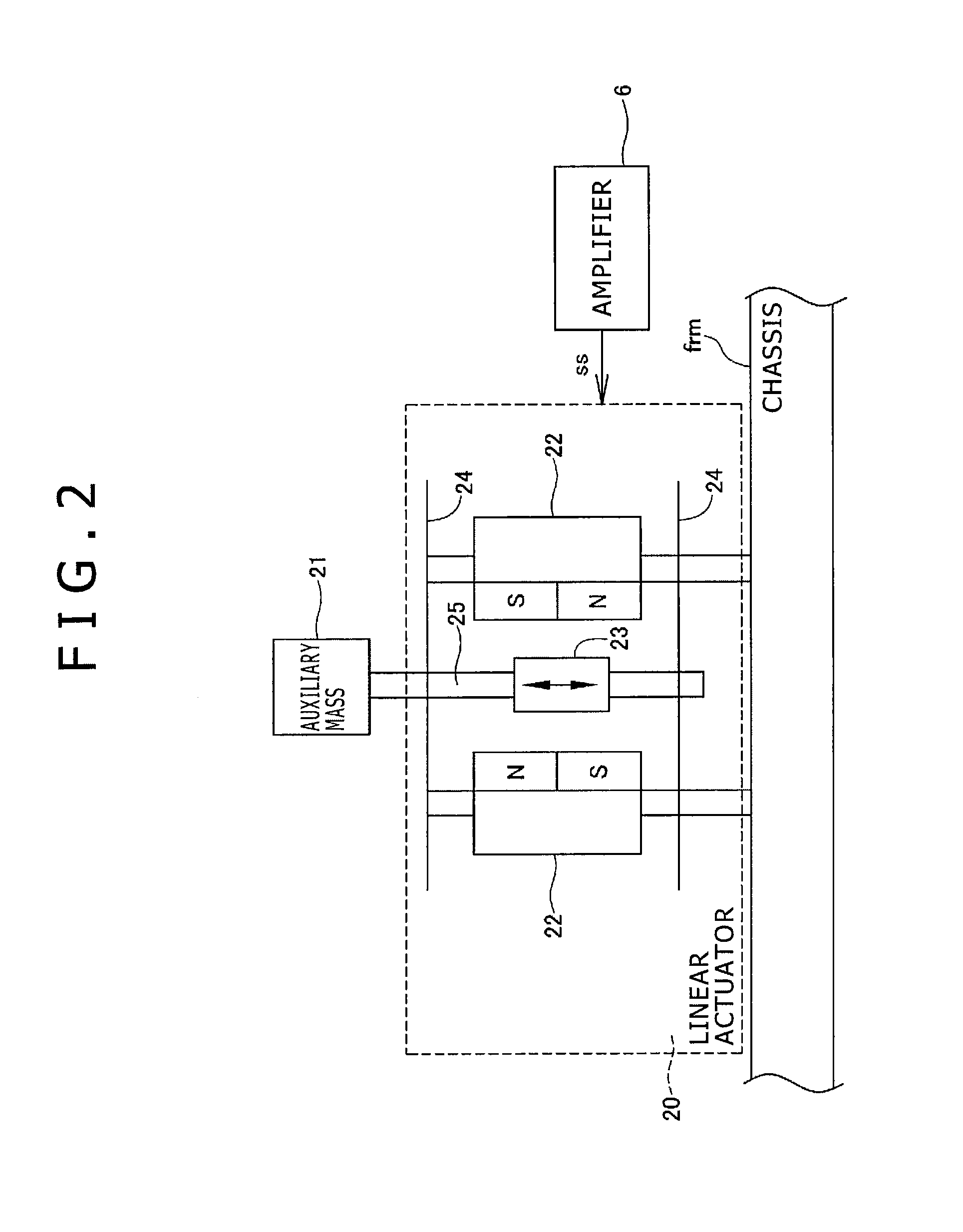

[0051]When the electric actuator driving apparatus of the present embodiment produces a driving instruction which is a periodic signal and inputs the driving instruction to drive an electric actuator, it produces a driving instruction signal based on an instruction vector having amplitude information and phase information corresponding to an amplitude and a phase of the driving instruction signal and is incorporated in the vibration damping apparatus. The vibration damping apparatus of the present embodiment is incorporated in a vehicle such as an automobile as shown in FIG. 1, and has vibration detection means 1 such as an acceleration sensor and so forth provided at a posit

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap