Pneumatic Tire

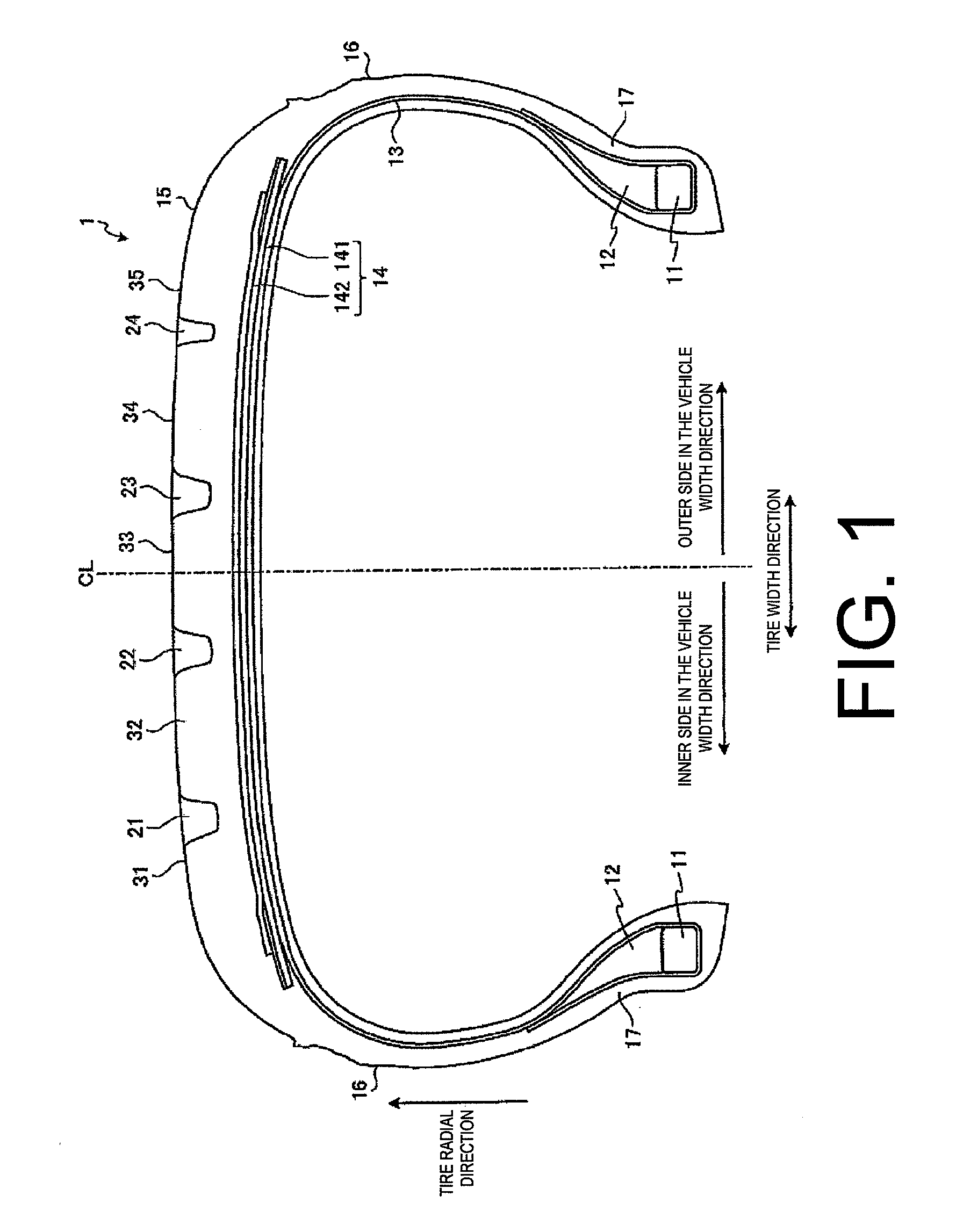

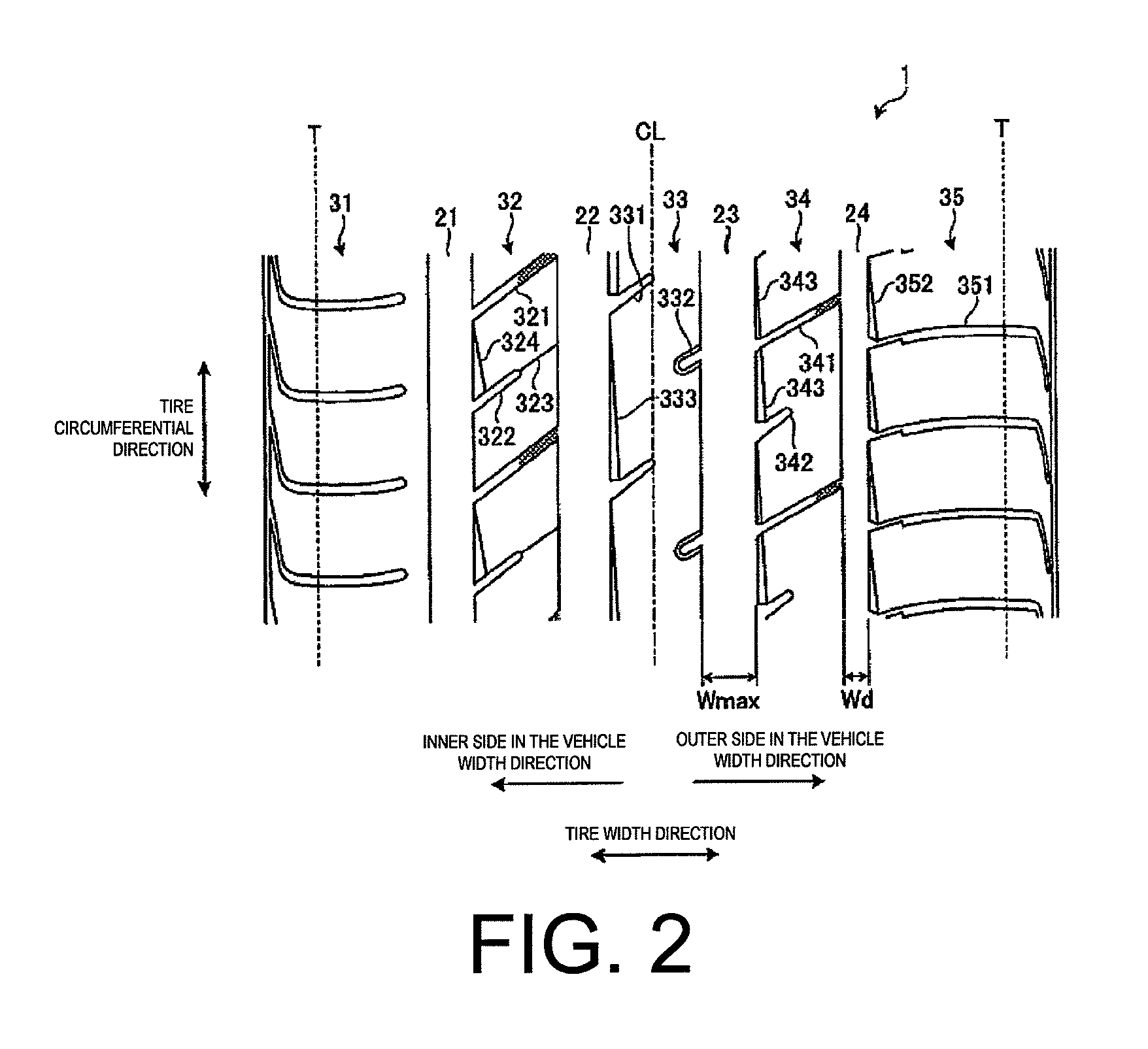

a technology of pneumatic tires and spherical plates, which is applied in the direction of vehicle components, non-skid devices, transportation and packaging, etc., can solve the problems of dry performance and wet performance of tires, and achieve the enhancement of water drainage properties of the region that has the inner side second land portion 32, the rigidity of the outer side second land portion 34

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0083]FIGS. 8a-8b include a table showing the results of performance testing of pneumatic tires according to embodiments of the present technology. FIGS. 9 and 10 are plan views illustrating treads of pneumatic tires of Conventional Examples 1 and 2.

[0084]In the performance testing, a plurality of mutually differing pneumatic tires were evaluated for (1) dry performance, and (2) wet performance (see FIGS. 8a-8b). In the performance tests, pneumatic tires with a tire size of 275 / 35R20 were assembled on a rim having a rim size of 20×9JJ (OE designated standard rim); and an air pressure of 260 kPa and a maximum load defined by JATMA were applied to these pneumatic tires, The pneumatic tires were mounted on a full-size sedan (not of Japanese make) used as a test vehicle.

[0085](1) In the evaluations for dry performance, the test vehicle was driven at a speed of from 60 km / h to 100 km / h on a flat circuit test course. Then, the test driver performed a sensory evaluation regarding steeri

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap