Sailboard with slotted winglets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

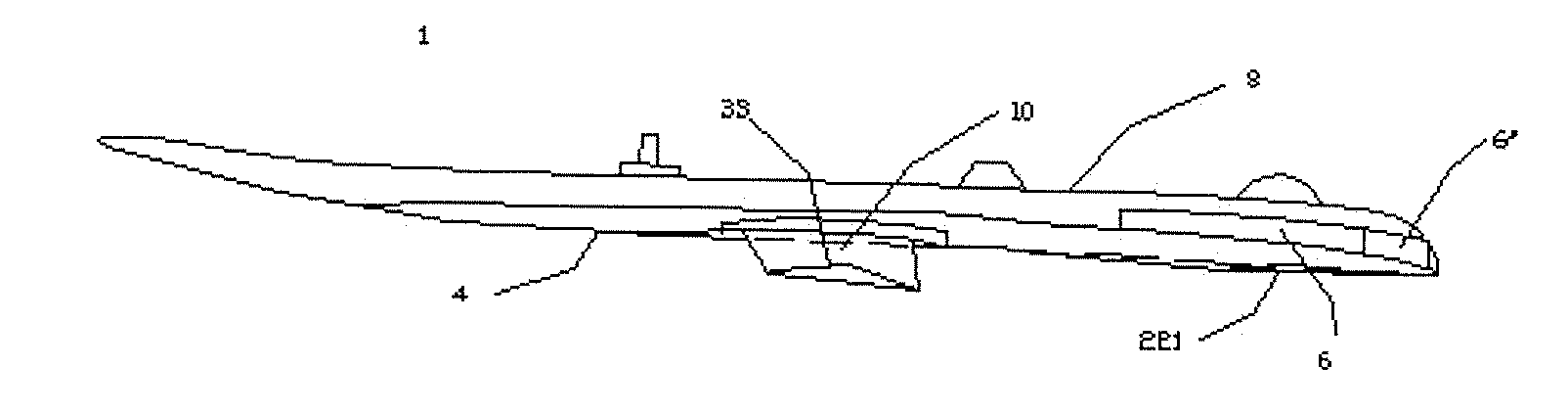

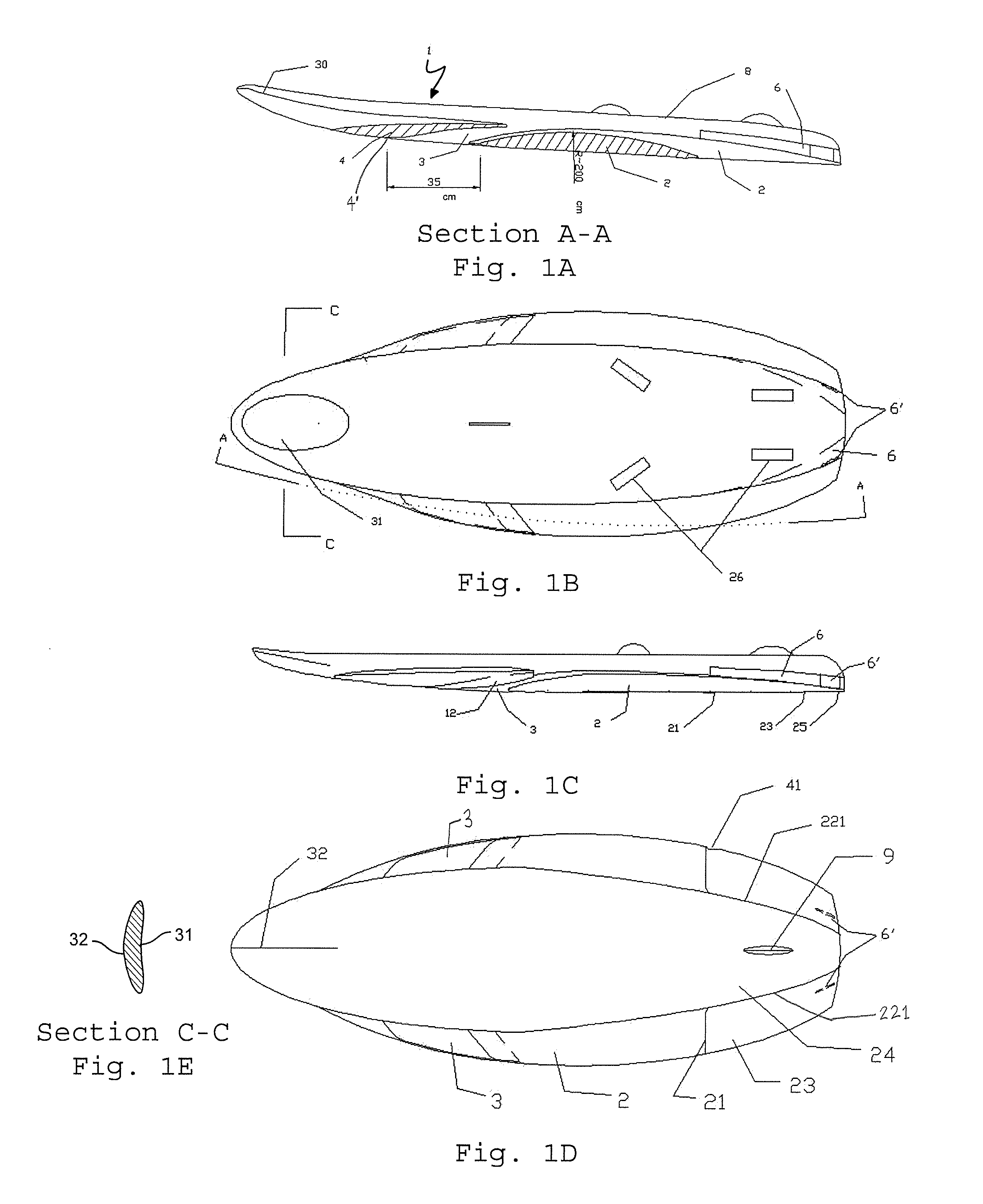

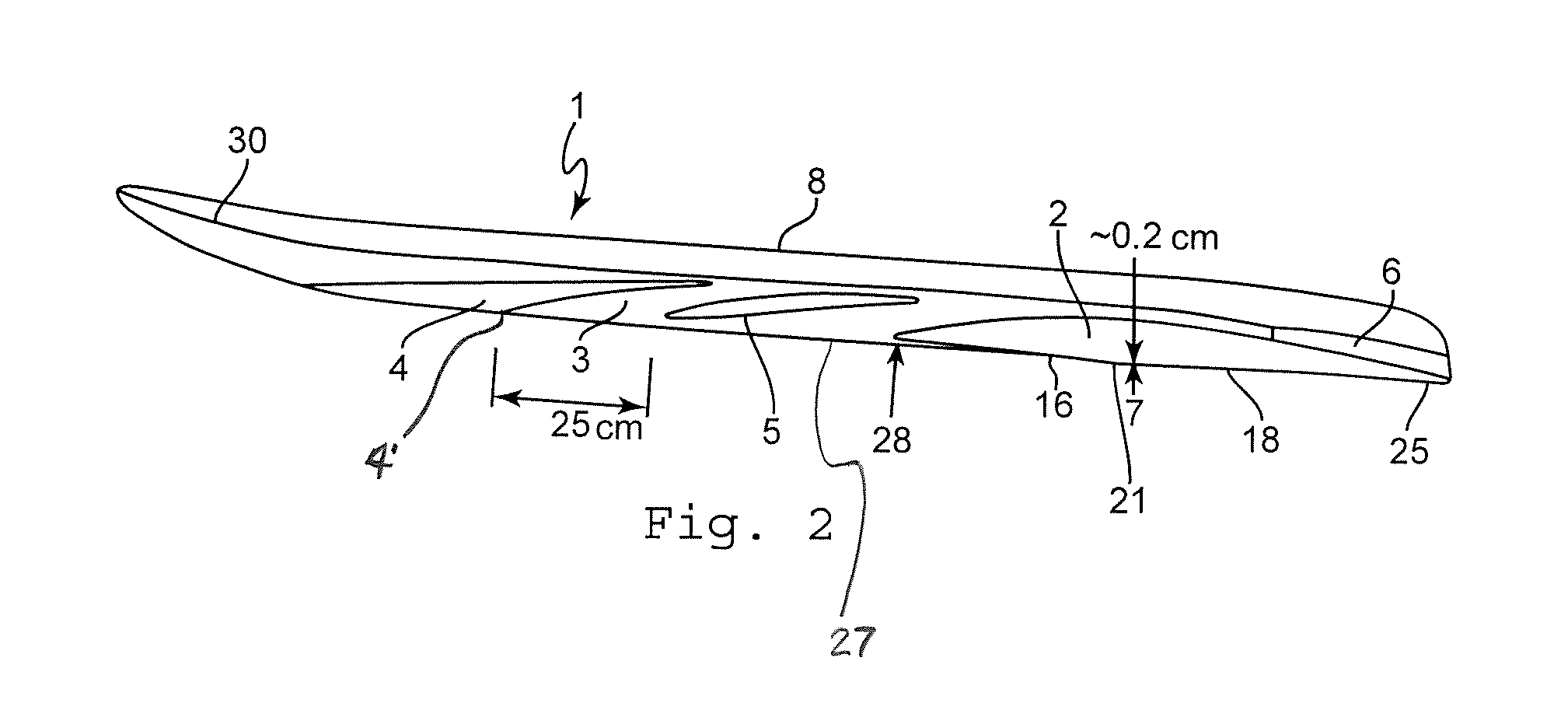

[0027]Referring now to the drawings, and more particularly to FIGS. 1A-1E, a cross section of a side part of a sailboard hull 1 is shown with a preferred embodiment of a winglet 2 with a front slot 3 and a top back slot 6. ‘Front slot’ and ‘forward slot’ are treated as substantially synonymous terms and may be used interchangeably herein. A ‘front slot’ or ‘forward slot’ may include an ‘opening’ or ‘forward opening’ which should also be understood as substantially synonymous. The term ‘top slot’ includes ‘back slot’ and ‘top black slot’. Hereafter a ‘winglet’2 may also be called a ‘slotted winglet’2 to emphasize the presence of a slot above the winglet. Winglet 2 has a length, in a longitudinal direction of the sailboard hull, at least 2 or 3 times its transverse width on each side of attachment to the main body. Thus it is distinguished from a fin or skeg at the side of the hull as in some racing catamaran sailboats. Winglet 2 may be integral with the sailboard hull such that the hull

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap