Back sheet for a solar cell module, and solar cell module comprising same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

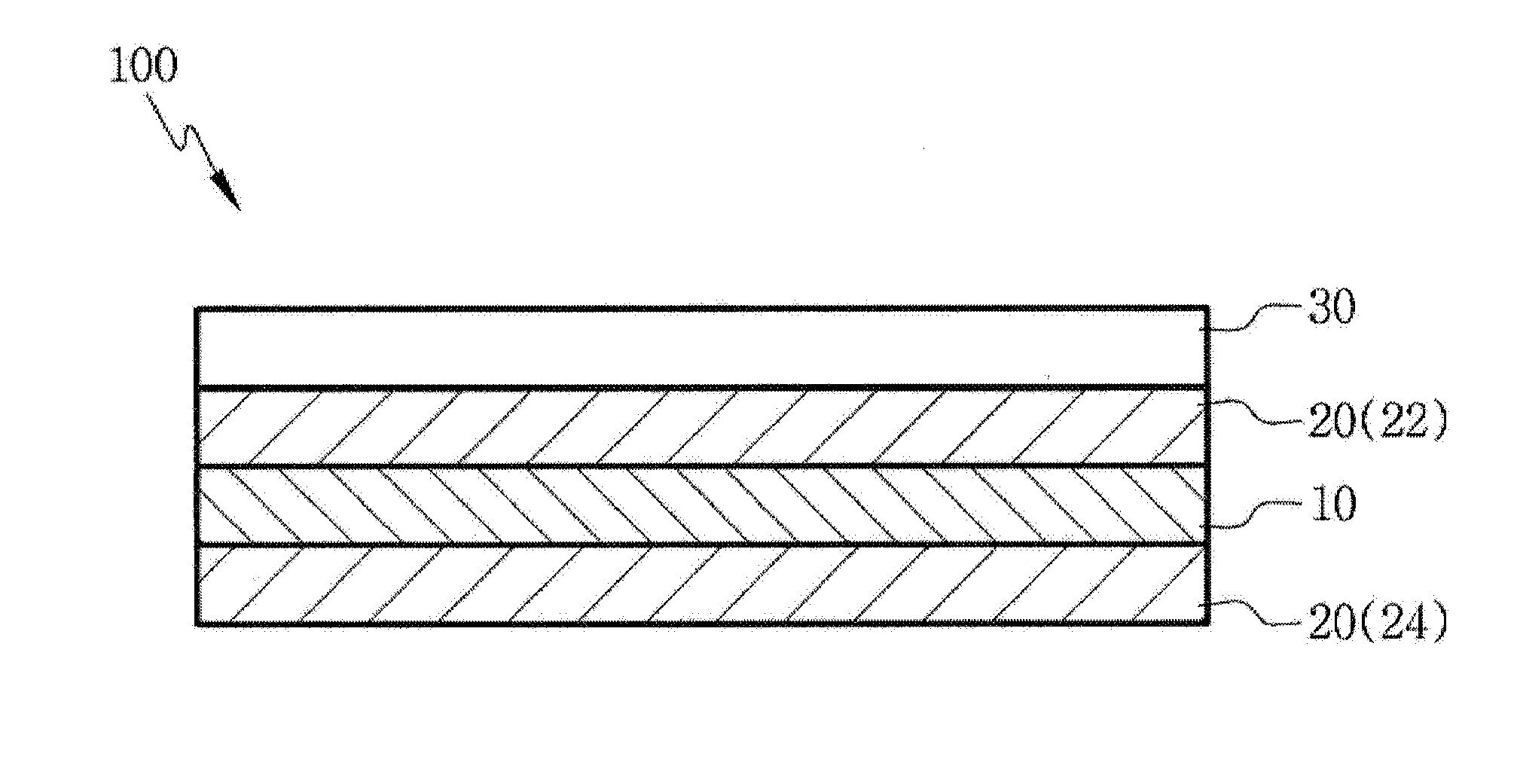

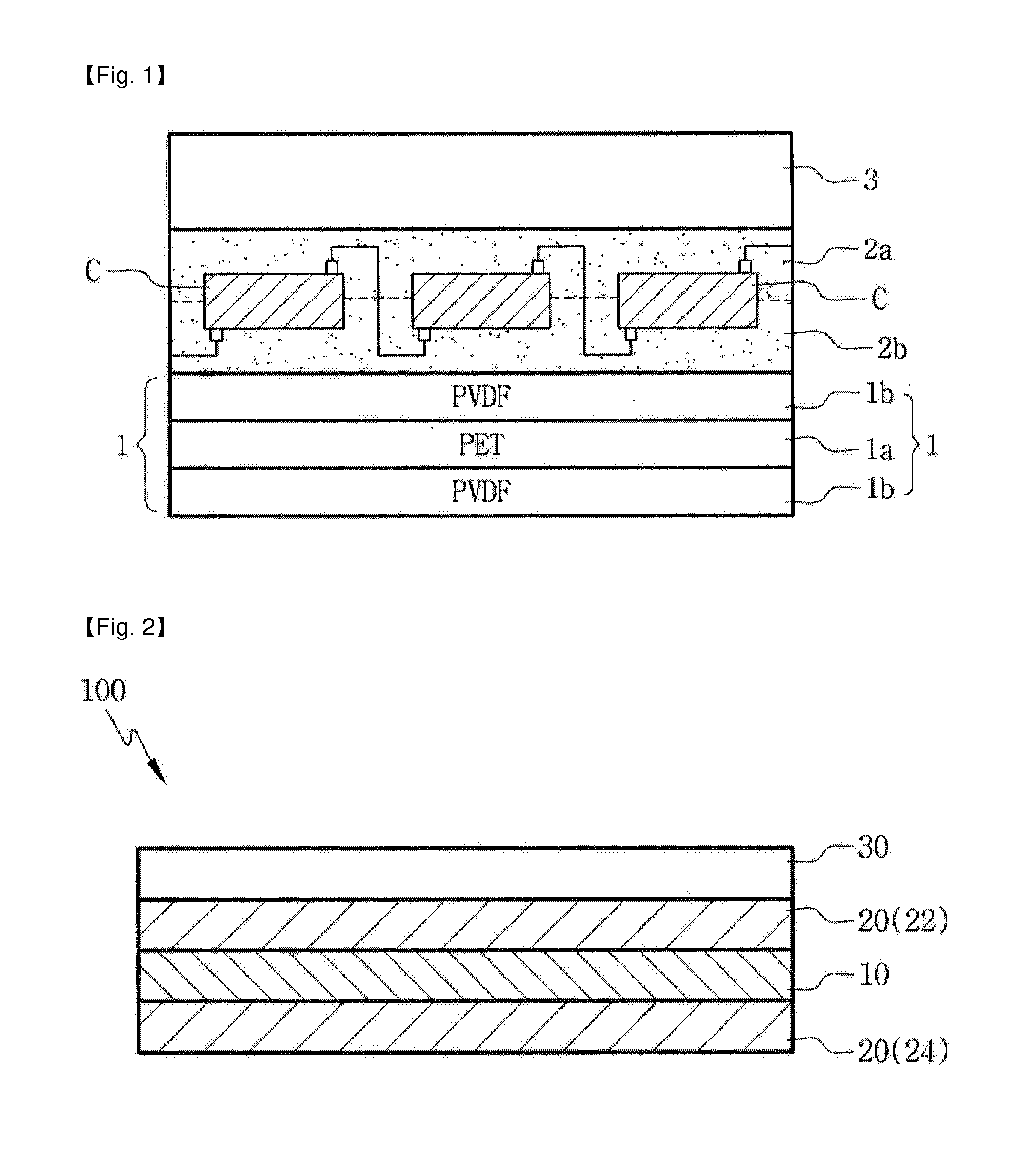

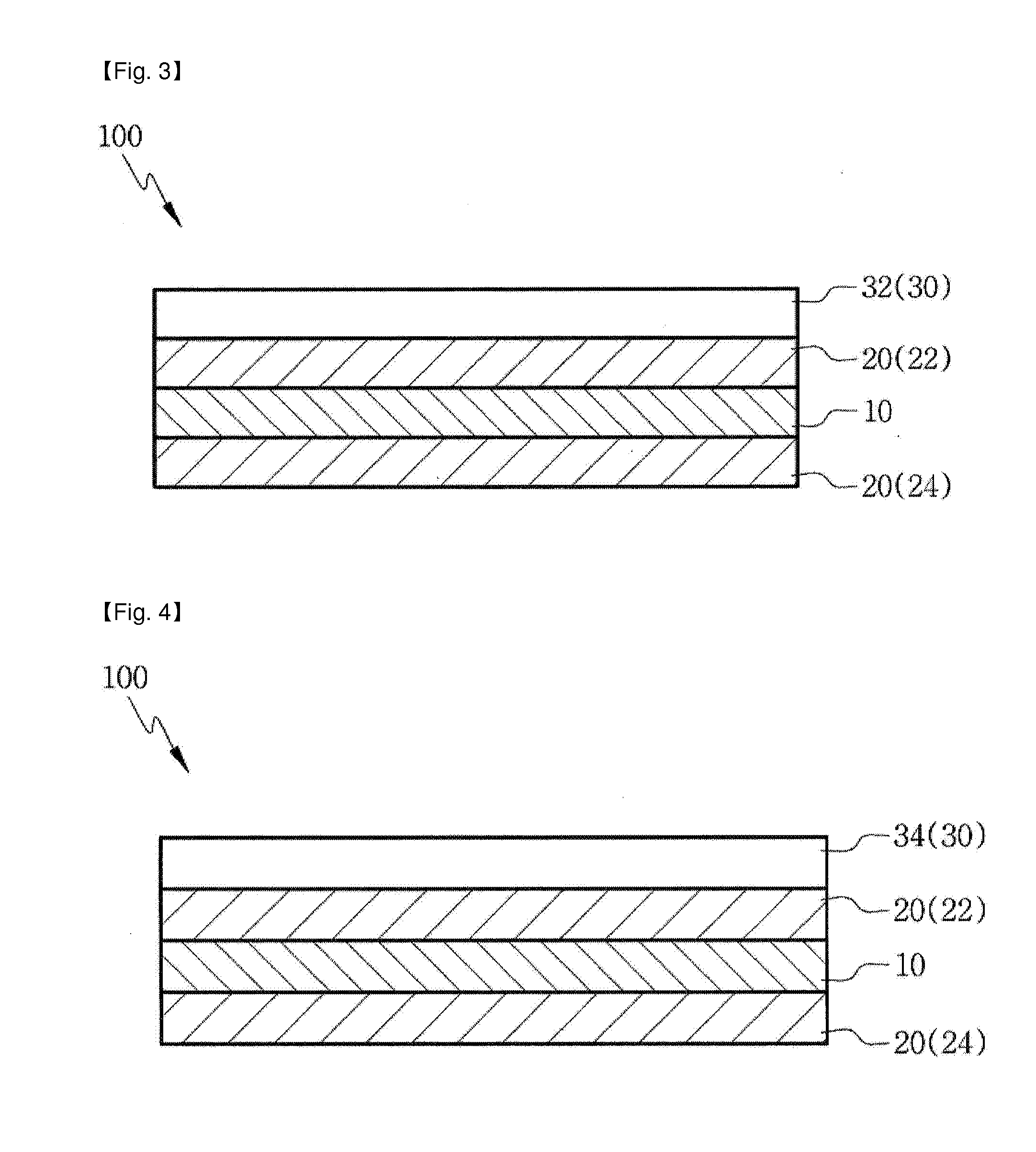

Image

Examples

example 1

[0104]10 parts by weight of titanium dioxide (TiO2) having an average particle size of 3 μm was mixed with 100 parts by weight of polyethylene (PE). The mixture was prepared into a 150-μm thick white PE film (hereinafter, referred to as ‘W-PE film’) through biaxial stretching.

[0105]After forming anticorrosion layers on both surfaces of a 80-μm thick aluminum (Al) film, the W-PE film (PE+TiO2) prepared above was attached on surface thereof using an acryl-based adhesive to prepare a back sheet having a stacked structure of W-PE film / anticorrosion layer / Al film / anticorrosion layer. The anticorrosion layer was formed by treating the both surfaces of the aluminum (Al) film with chromic acid to a thickness of about 1 μm.

example 2

[0106]A back sheet was prepared in the same manner as in Example 1, except for further forming a fluorine coating layer.

[0107]Specifically, a back sheet having a stacked structure of W-PE film / anticorrosion layer / Al film / anticorrosion layer / fluorine coating layer was prepared by gravure-coating and hardening a fluorine resin composition obtained by mixing PTFE and ethanol at 1:1 (weight ratio) on an anticorrosion layer with no W-PE film (PE+TiO2) attached to a thickness of 20 μm.

example 3

[0108]A back sheet was prepared in the same manner as in Example 1, except for further forming a heat-dissipating ink coating layer. Specifically, a back sheet having a stacked structure of W-PE film / anticorrosion layer / Al film / anticorrosion layer / heat-dissipating ink coating layer was prepared by gravure-coating and hardening a liquid ink composition including an acryl resin and a graphite powder at a weight ratio of 1:1 on an anticorrosion layer to a thickness of 25 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap