Optical waveguide element

a technology of optical waveguides and elements, applied in non-linear optics, instruments, optics, etc., can solve the problems of affecting the operation point of a product, affecting the efficiency of the manufacturing process, so as to achieve efficient diffusion of charges generated in the substrate, efficiently dispersed, and efficient dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]Hereinafter, an optical waveguide element of the present invention will be described in detail.

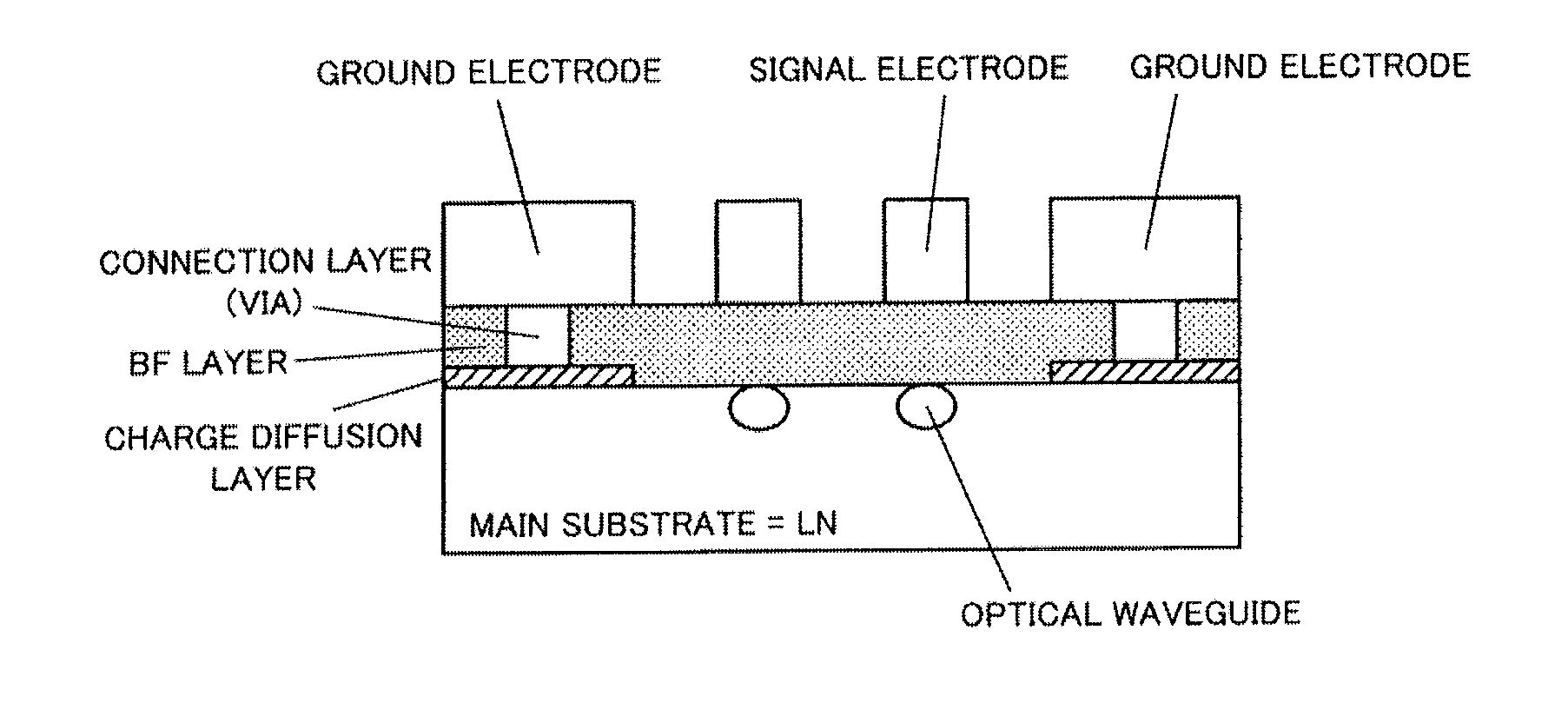

[0035]As illustrated in FIG. 1, the optical waveguide element of the present invention is an optical waveguide element including a substrate having an electro-optical effect, optical waveguides formed in the substrate, a buffer layer (BF layer) formed on the substrate, and modulation electrodes (signal electrode and ground electrode) that are formed on the buffer layer and modulate optical waves propagating through the optical waveguides, in which a charge diffusion layer that diffuses charges generated in the substrate is formed between the substrate and the buffer layer, and the charge diffusion layer is electrically connected with a ground electrode constituting the modulation electrode.

[0036]As the substrate used in the present invention, a substrate for which a material having an electro-optical effect can be used, and, for example, a substrate made of lithium niobate, lithium tant

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap