Door closer with tri-lobe pinion

a tri-lobe pinion and door closer technology, applied in the field of door closers, can solve the problems that the installer of the door closer may have difficulty in identifying the correct orientation, and achieve the effect of reducing the number of incorrect shaft/arm mounting orientations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

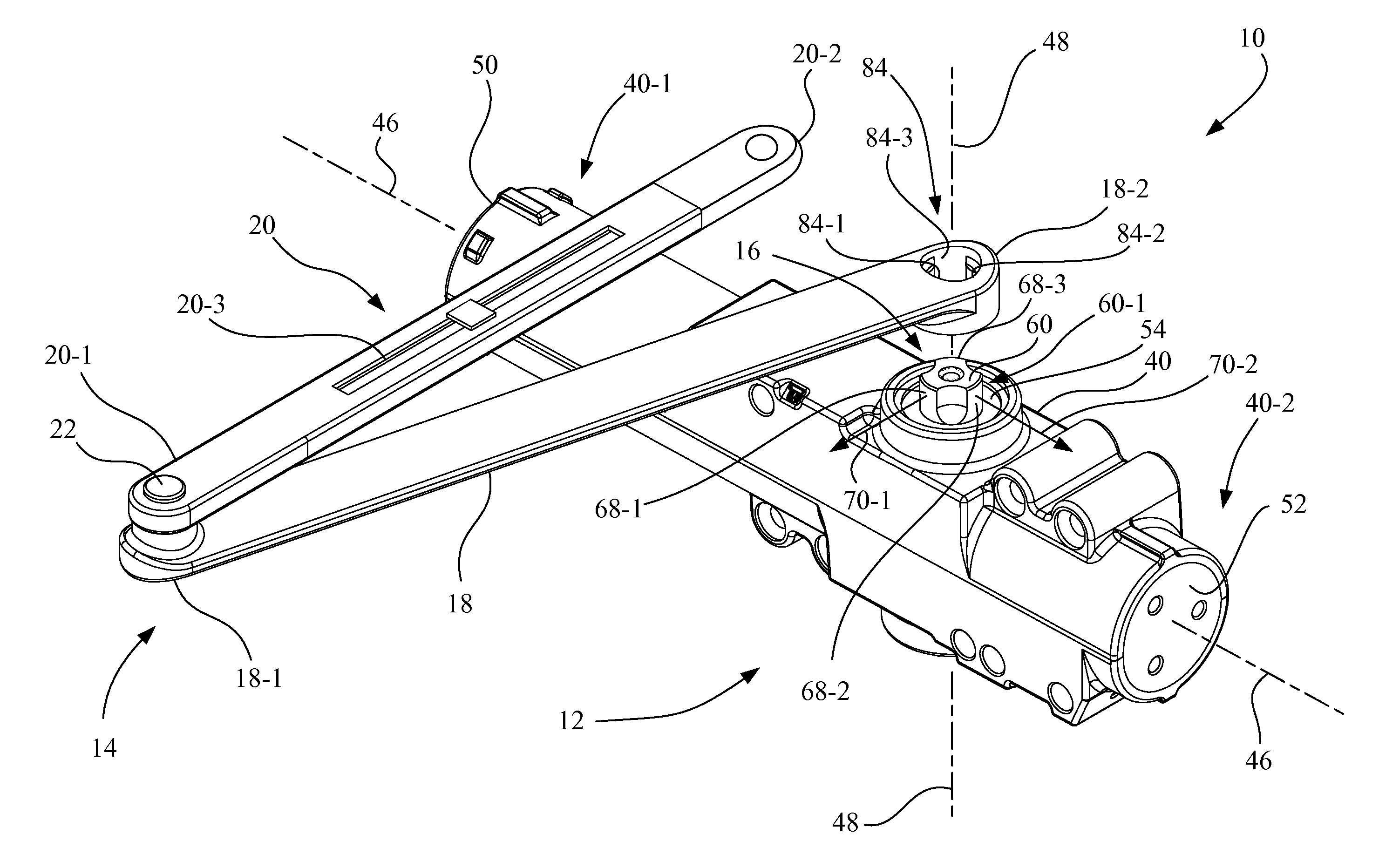

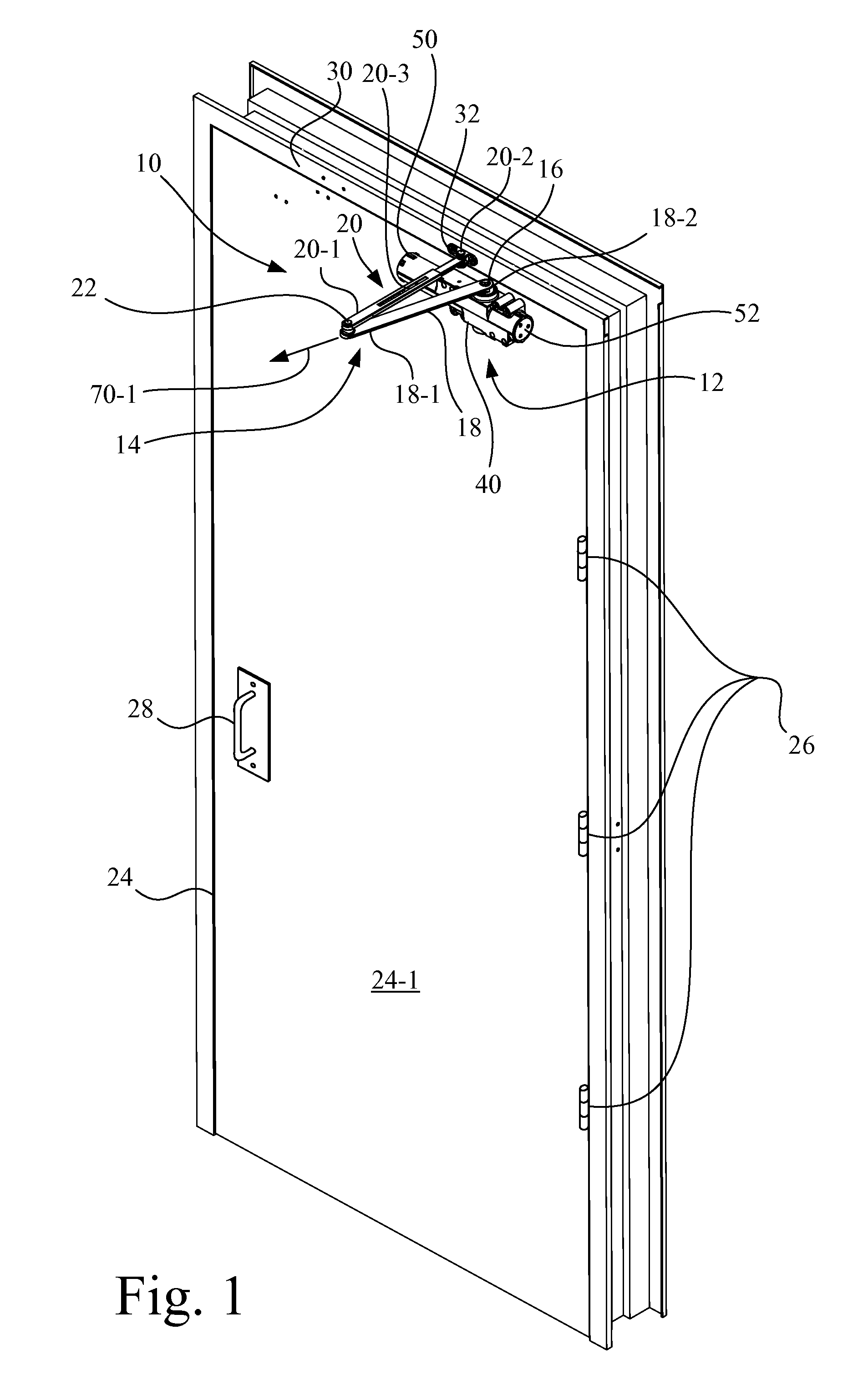

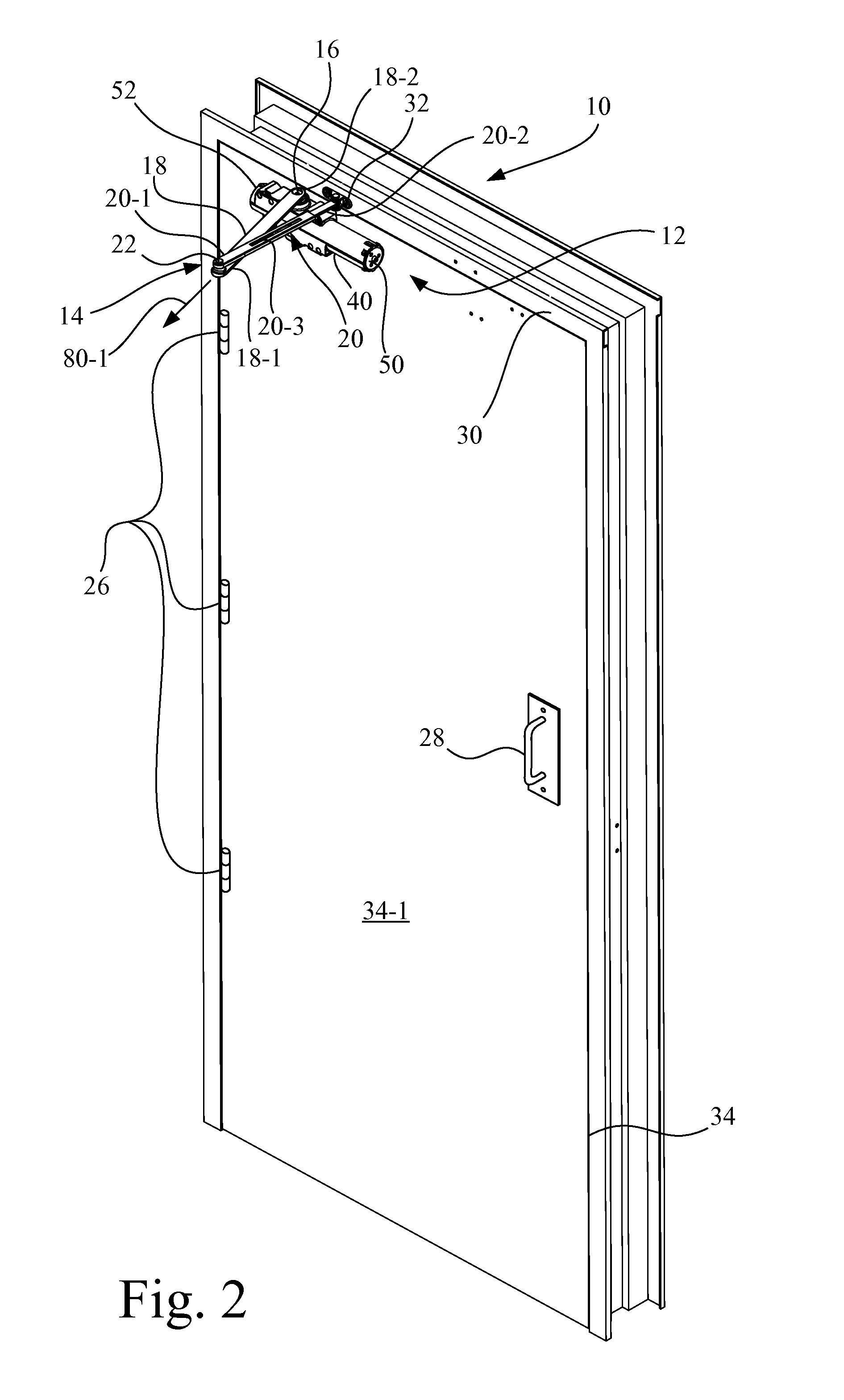

[0032]Referring now to the drawings and particularly to FIGS. 1-4, there is shown a door closer assembly 10 of the present invention, including a door closer 12 and a door closer arm assembly 14. Door closer 12 includes a rotatable pinion 16. Door closer arm assembly 14 is in the form of an articulating linkage that includes a main closer arm 18 and a secondary closer arm 20.

[0033]Main closer arm 18 and a secondary closer arm 20 are pivotally joined at respective ends 18-1, 20-1 at a pivot joint 22. Pivot joint 22 may be, for example, a pin / hole arrangement. A mounting end 18-2 of the main closer arm 18 is connected to pinion 16 of the door closer 12. Secondary closer arm 20 has a mounting end 20-2, and may have a length adjustment mechanism 20-3. Length adjustment mechanism 20-3 may be, for example, in the form of a pair of adjustable slide bars, as in the embodiment shown, or may be a threaded rod / nut, or turnbuckle, type of arrangement.

[0034]Referring to FIG. 1, door closer asse

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap