Method for disassembling and/or assembling an underwater section of a retractable thruster unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

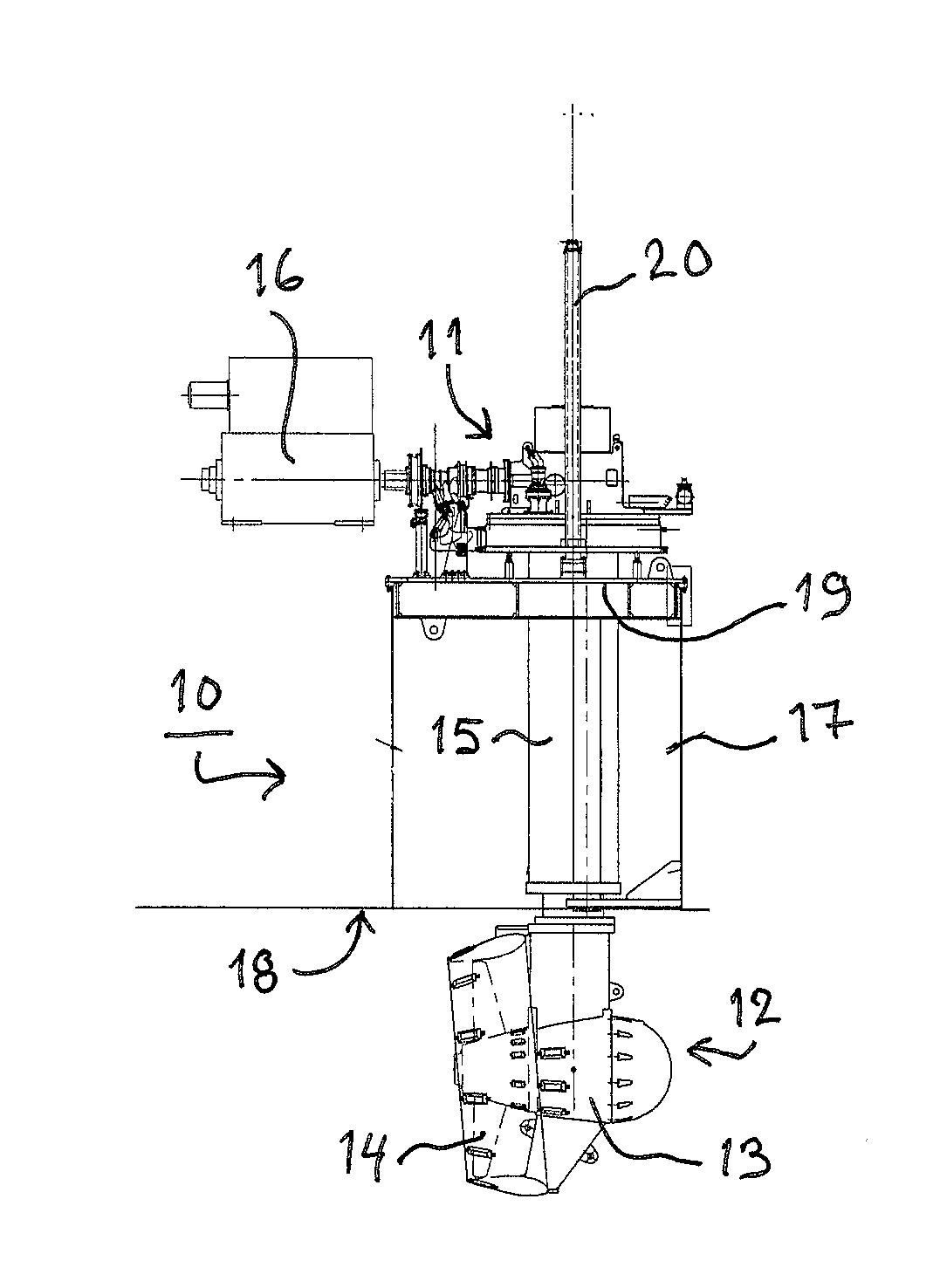

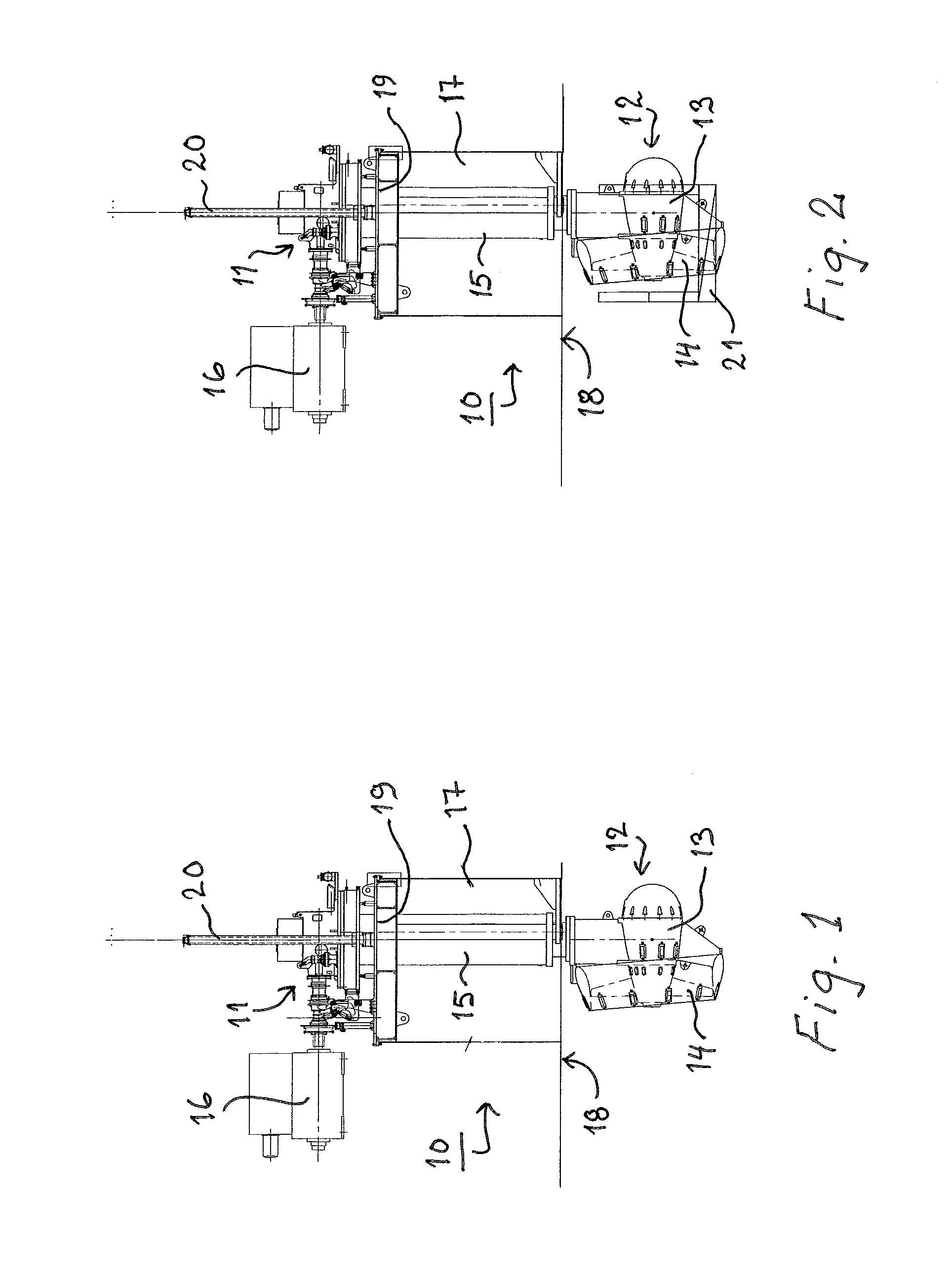

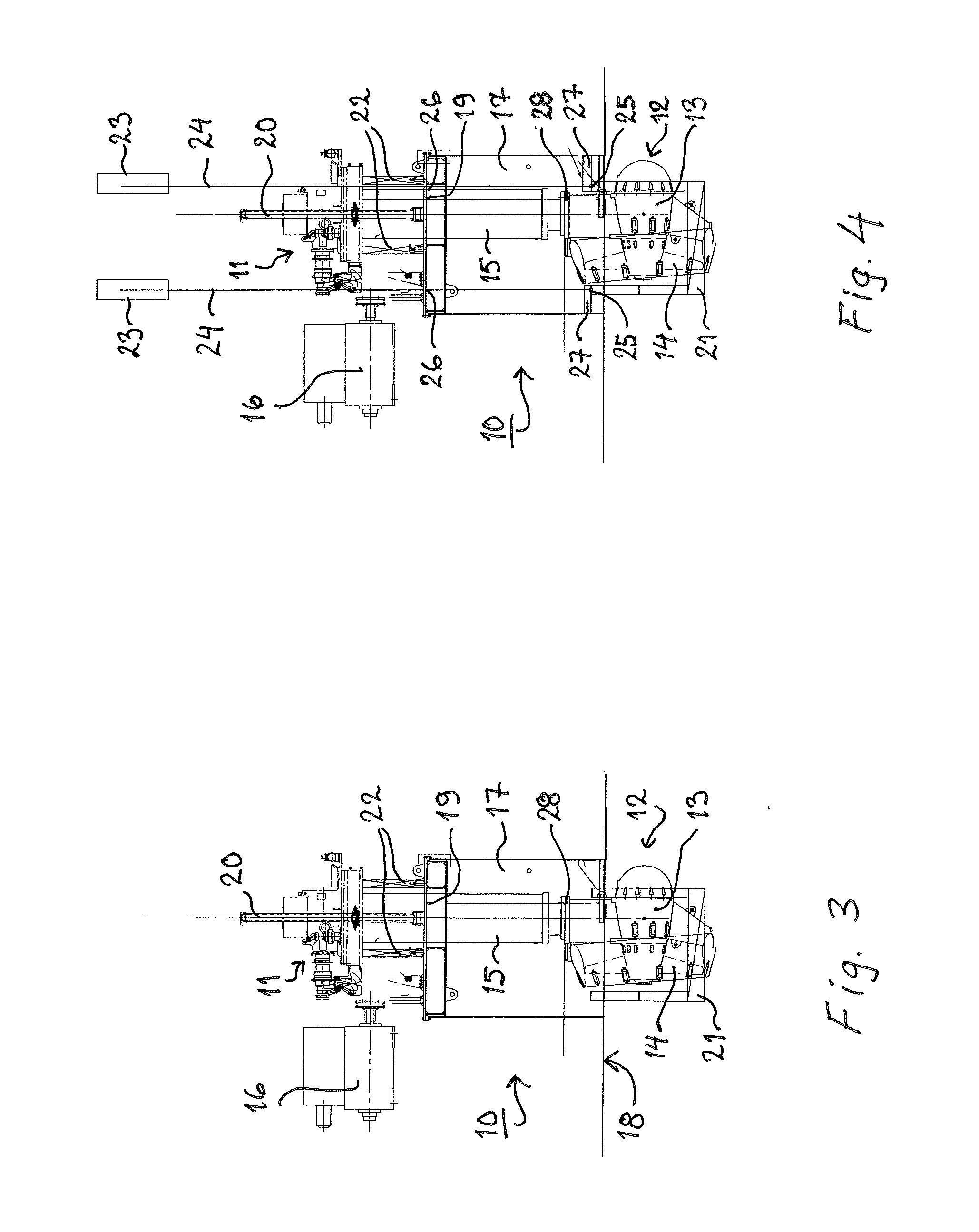

[0017]FIG. 1 shows an azimuthing thruster unit 10 which is turnable around a vertical axis for steering. The thruster unit 10 comprises an upper gear 11 connected to a power source 16, an underwater section 12 including a lower gear 13 connected to the actual propeller 14, and a vertical steering tube 15 connecting the upper gear 11 with the lower gear 13. Said steering tube 15 contains a vertical shaft through which power and torque are transmitted from the upper gear 11 to the lower gear 13.

[0018]The thruster unit 10 is mounted in a swimming vessel so that a well 17 is formed in the bottom 18 of the vessel. The well 17 is open downwards but the top of the well is provided with a covering plate 19 by which the well 17 is sealed and closed upwards. As shown in the drawings the upper gear 11 of the thruster unit 10 is placed above the covering plate 19 which is provided with a sealed lead-in through which the vertical steering tube 15 extends from the upper gear 11 to the lower gear 13

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap