Adjustable Shelving System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

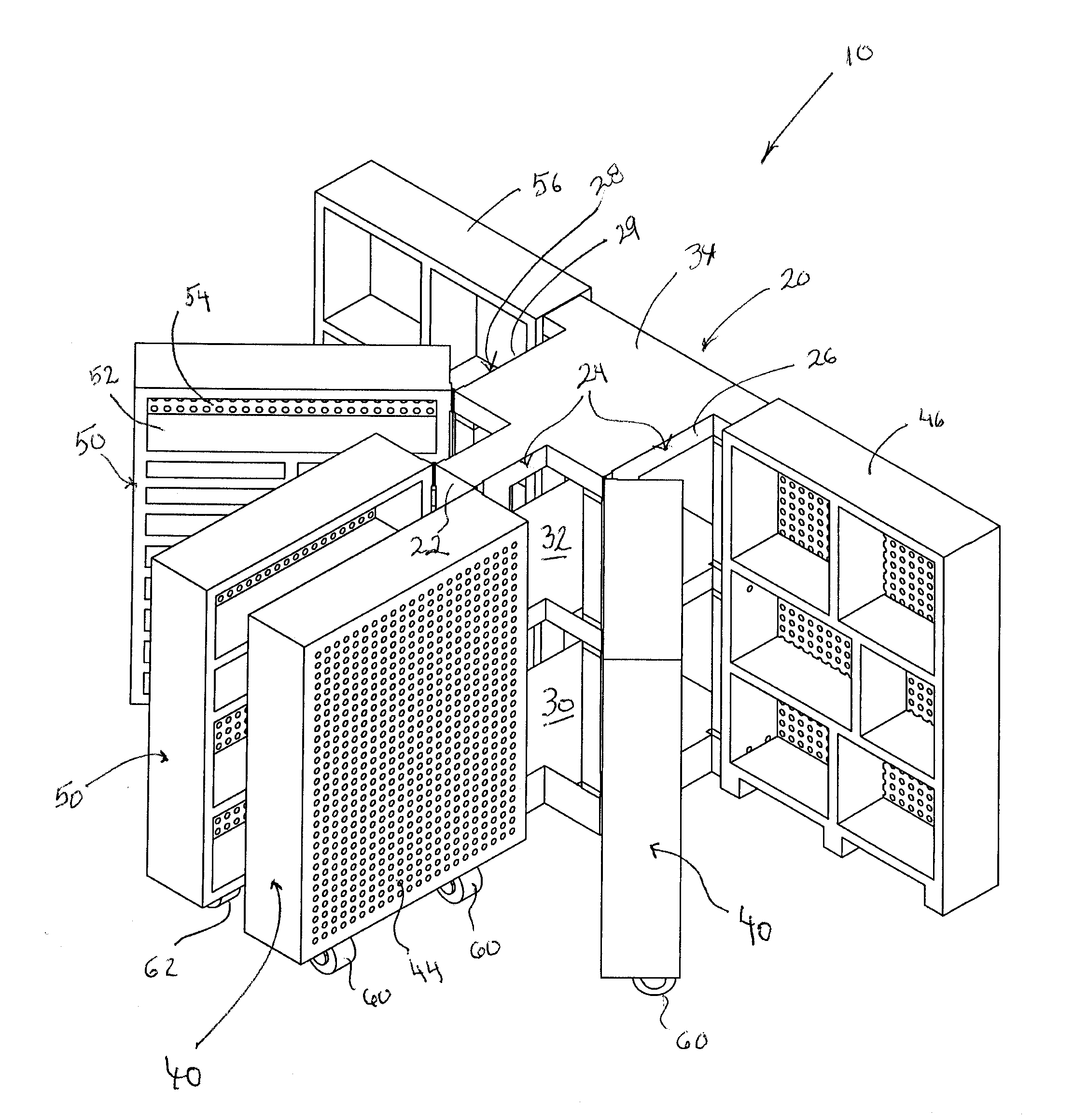

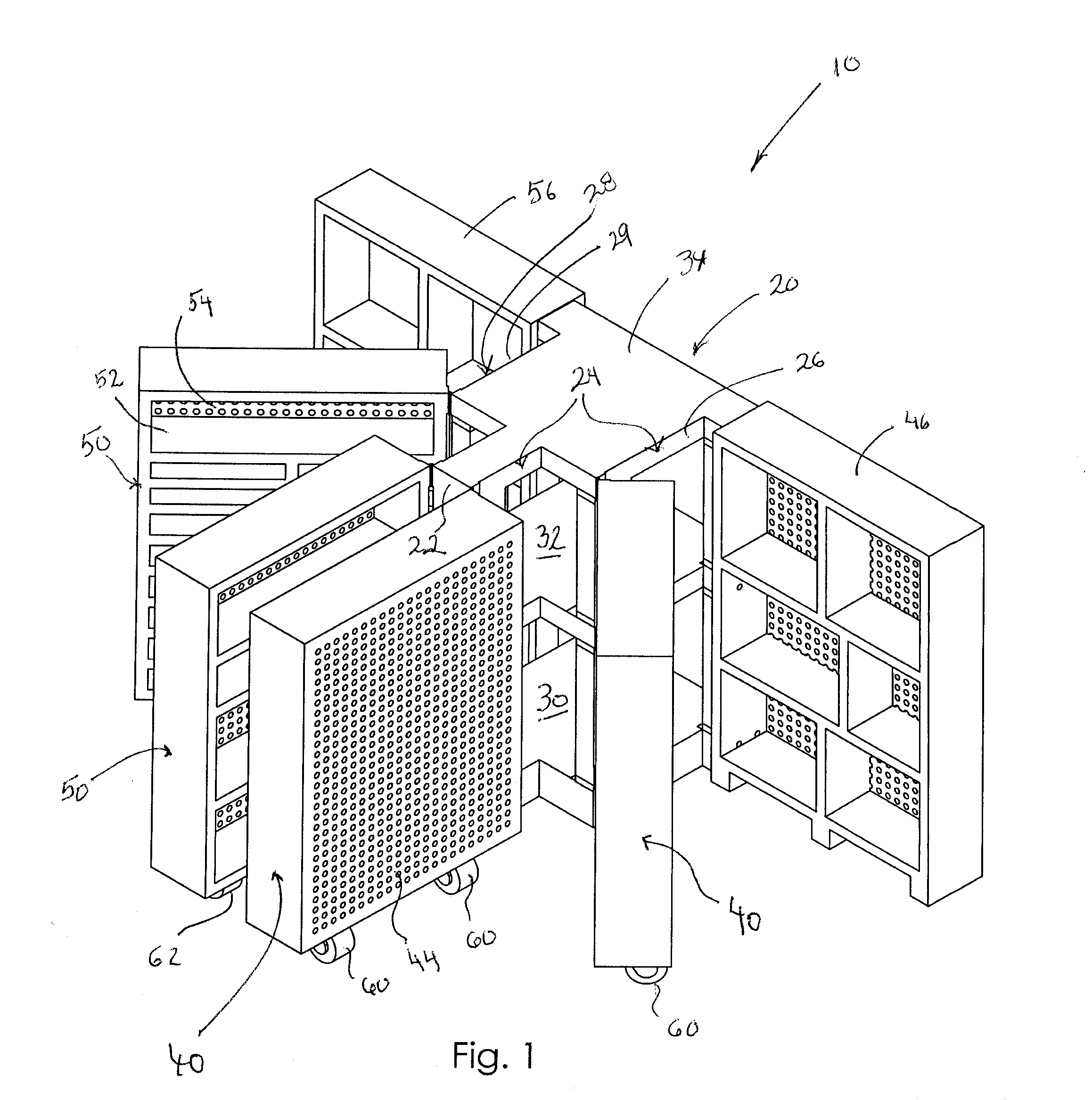

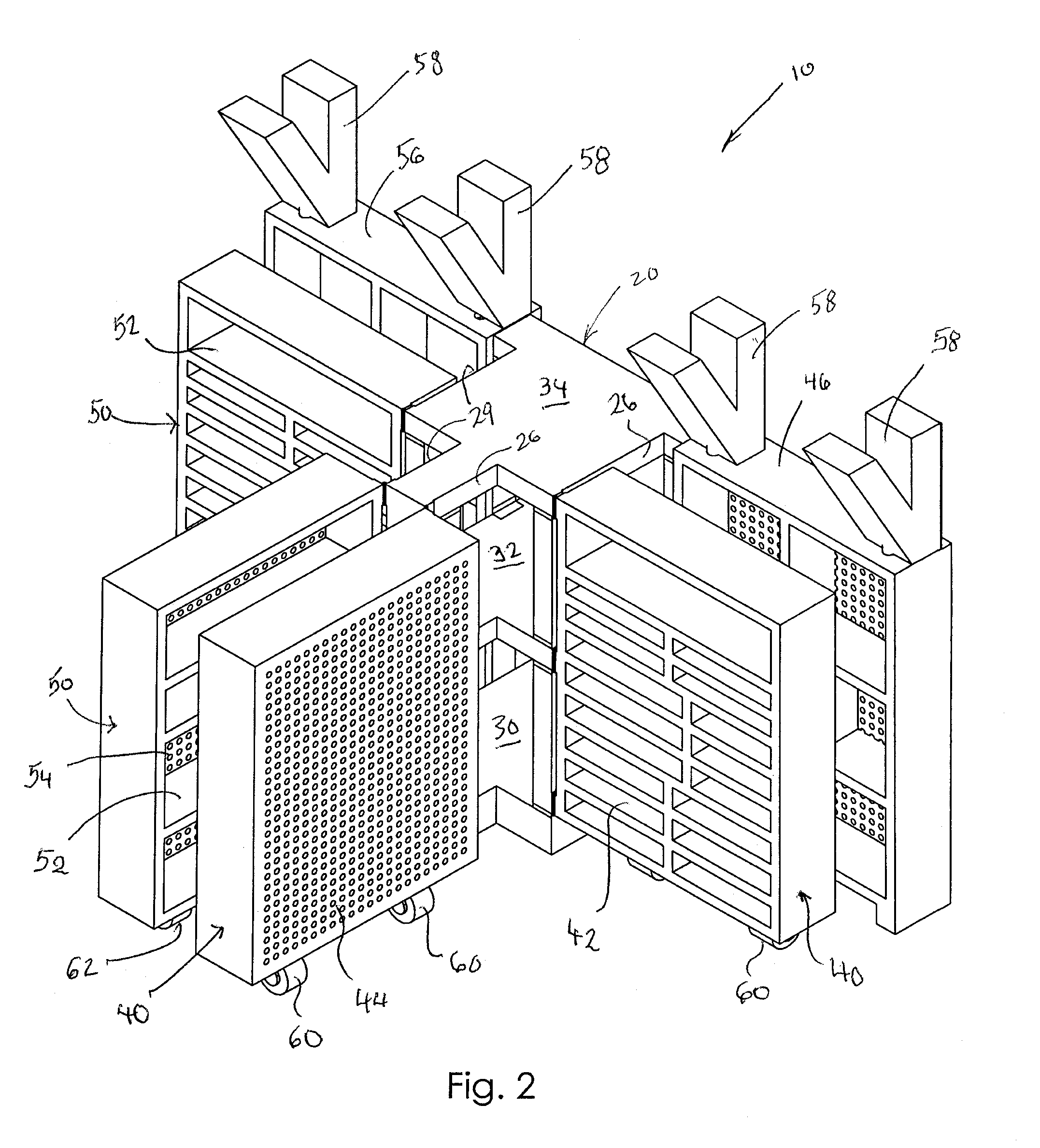

[0036]An adjustable shelving system according to a preferred embodiment of the present invention will now be described in detail with reference to FIGS. 1 to 13b of the accompanying drawings. The shelving system 10 includes a base member 20 (also referred to as a base shelving unit), a plurality of first shelf assemblies 40 pivotally coupled to a first side 24 of the base member 20, and a plurality of second shelf assemblies 50 pivotally coupled to a second side 28 of the base member 20. One or more rollers may be coupled to a bottom surface of each shelf assembly to facilitate movement thereof. Each shelf assembly may be pivotally coupled to the base member 20 with a floating hinge 70 that enables a respective shelf assembly to float upward or downward as it moves on an uneven floor surface or over a small obstacle.

[0037]The base member 20 is a shelving unit having a base portion, intermediate portion, and top portion (FIG. 1). The base member 20 includes a front side, back side, firs

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap