Vehicle control system for internal combustion engine

a technology of control system and internal combustion engine, which is applied in the direction of electric control, ignition automatic control, machines/engines, etc., can solve the problems of reducing the wall temperature of the combustion chamber and deteriorating overall exhaust performance, so as to reduce the number of exhaust particles and reduce the adhesion of fuel to the wall surface of the combustion chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

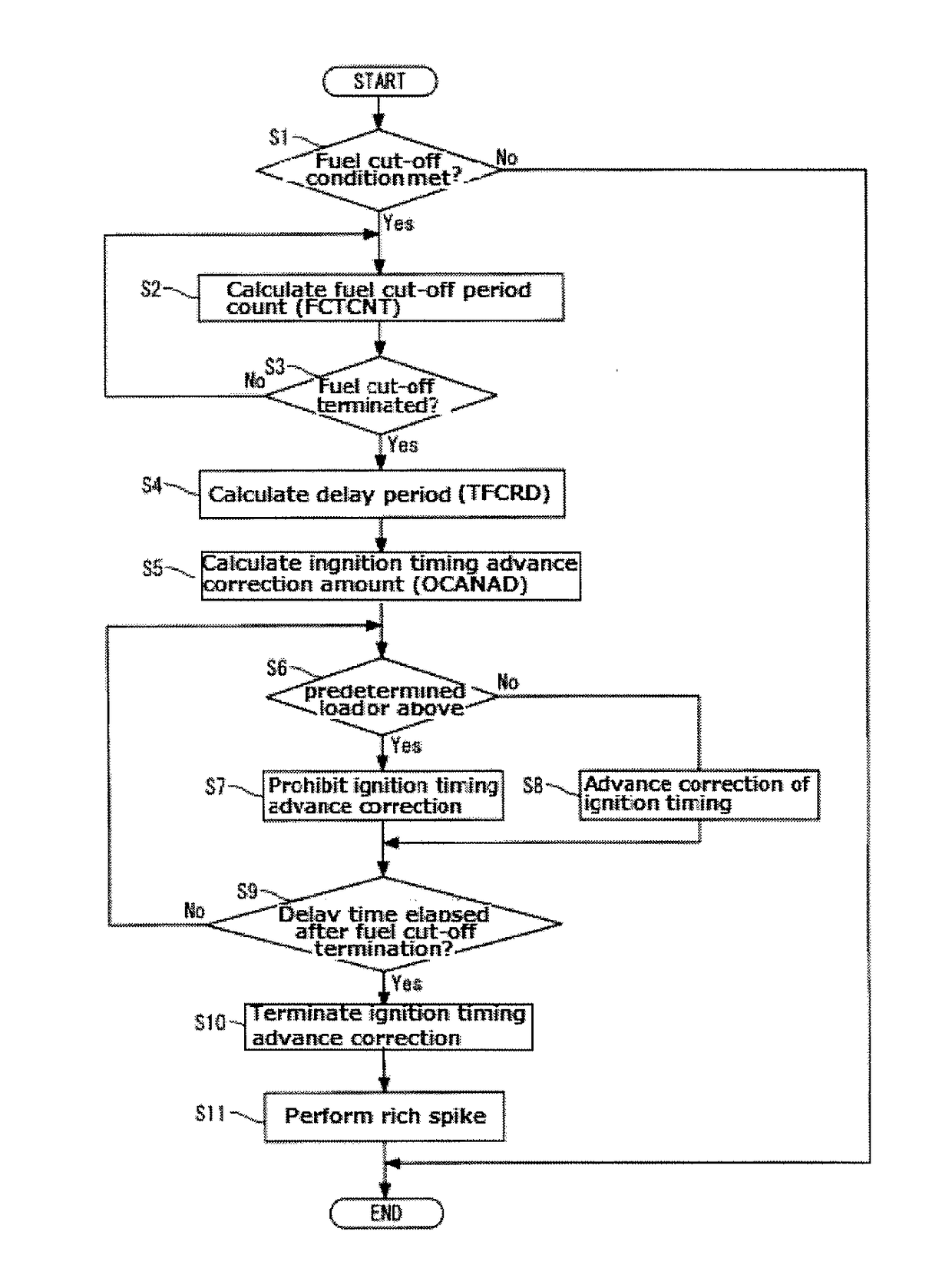

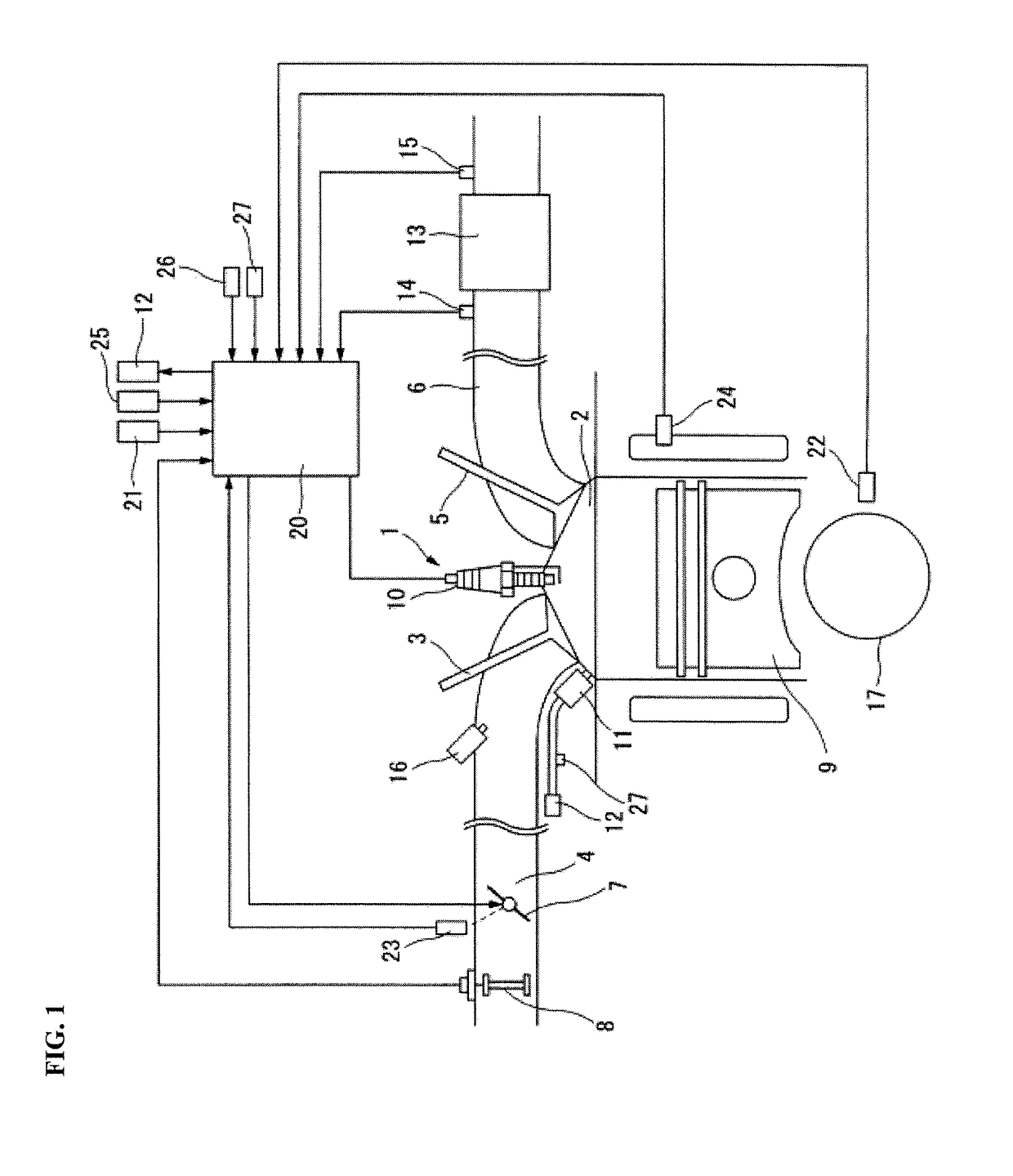

[0015]Below, embodiments of the present invention are described in detail with reference to the accompanying drawings. In embodiments of the invention, numerous specific details are set forth in order to provide a more thorough understanding of the invention. However, it will be apparent to one of ordinary skill in the art that the invention may be practiced without these specific details. In other instances, well-known features have not been described in detail to avoid obscuring the invention. FIG. 1 shows a schematic configuration of an internal combustion engine 1 according to one or more embodiments of the present invention. Note that the internal combustion engine 1 uses gasoline as fuel, for example.

[0016]A combustion chamber 2 of the internal combustion engine 1 is connected to an intake passage 4 with an intake valve 3 interposed. Further, the combustion chamber 2 is connected to an exhaust passage 6 with an exhaust valve 5 interposed.

[0017]In the intake passage 4, a throttle

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap