Additive manufacturing arrangement with shared radiation source

a technology of additive manufacturing and radiation source, applied in the field of additive manufacturing, can solve the problems of reducing yield, affecting compliance, increasing energy deposition artifacts, etc., and achieves the effects of reducing costs, high and consistent yield, and reducing varian

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

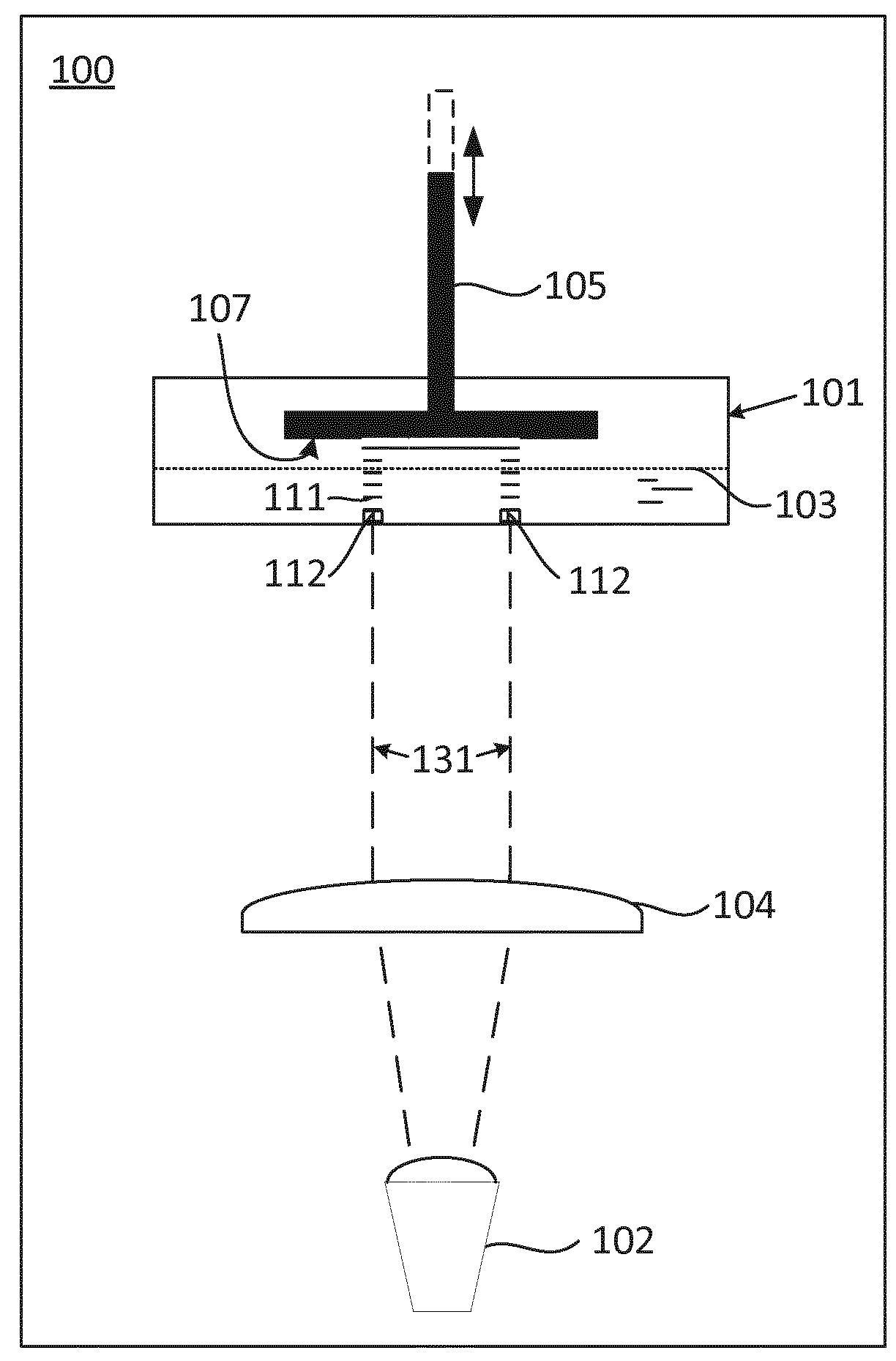

[0042]FIG. 1 generically illustrates a bottom-projection type of additive manufacturing apparatus 100. It comprises a vat 101 or other suitable container for holding a radiation-curable liquid 103 (indicated by its surface); a movable platform 105 having a build surface 107 that can be moved relative to the vat e.g. as indicated by the double arrow; and a radiation source 102 for providing hardening radiation 131 for selectively solidifying radiation-curable liquid in the vat. A lens system 104 focuses the radiation onto the radiation-curable liquid. The radiation source can provide radiation in a pattern corresponding to a layer to be formed. Element 111 illustrates already formed layers. Element 112 illustrates a newly formed layer, the shape of which is defined by the pattern provided by the radiation source. The radiation-curable liquid 103 and layers 111 and 112 are not part of the apparatus but are included to illustrate how a product is manufactured during an additive manufactur

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap