Production method for a component having integrated channels and component

a production method and integrated channel technology, applied in the direction of turbines, machines/engines, manufacturing tools, etc., can solve the problems of low productivity, inadequate product benefits, and currently only limited options for combining additive manufacturing processes with established manufacturing techniques

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025]Identical reference designations have the same meaning in the various figures.

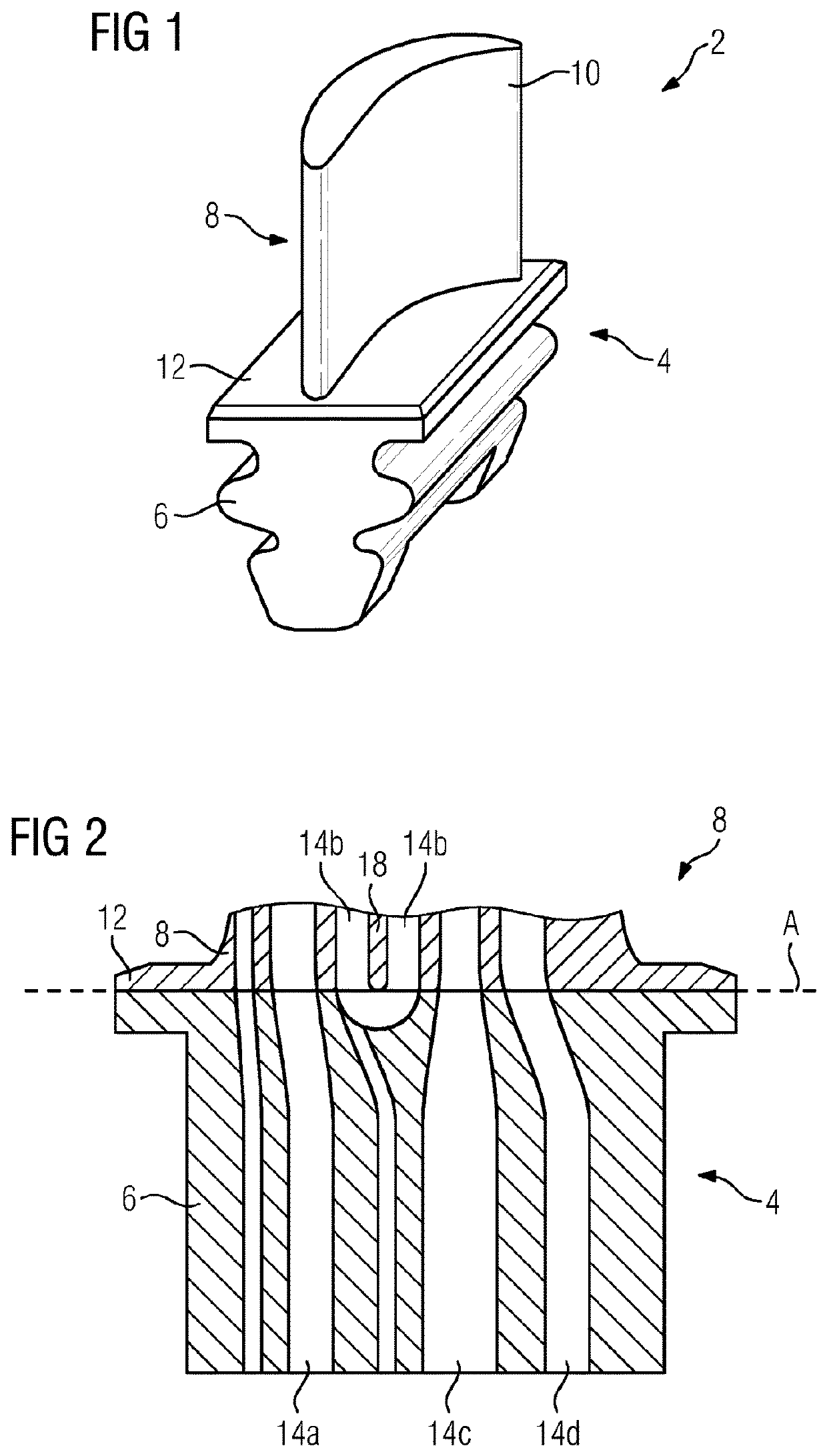

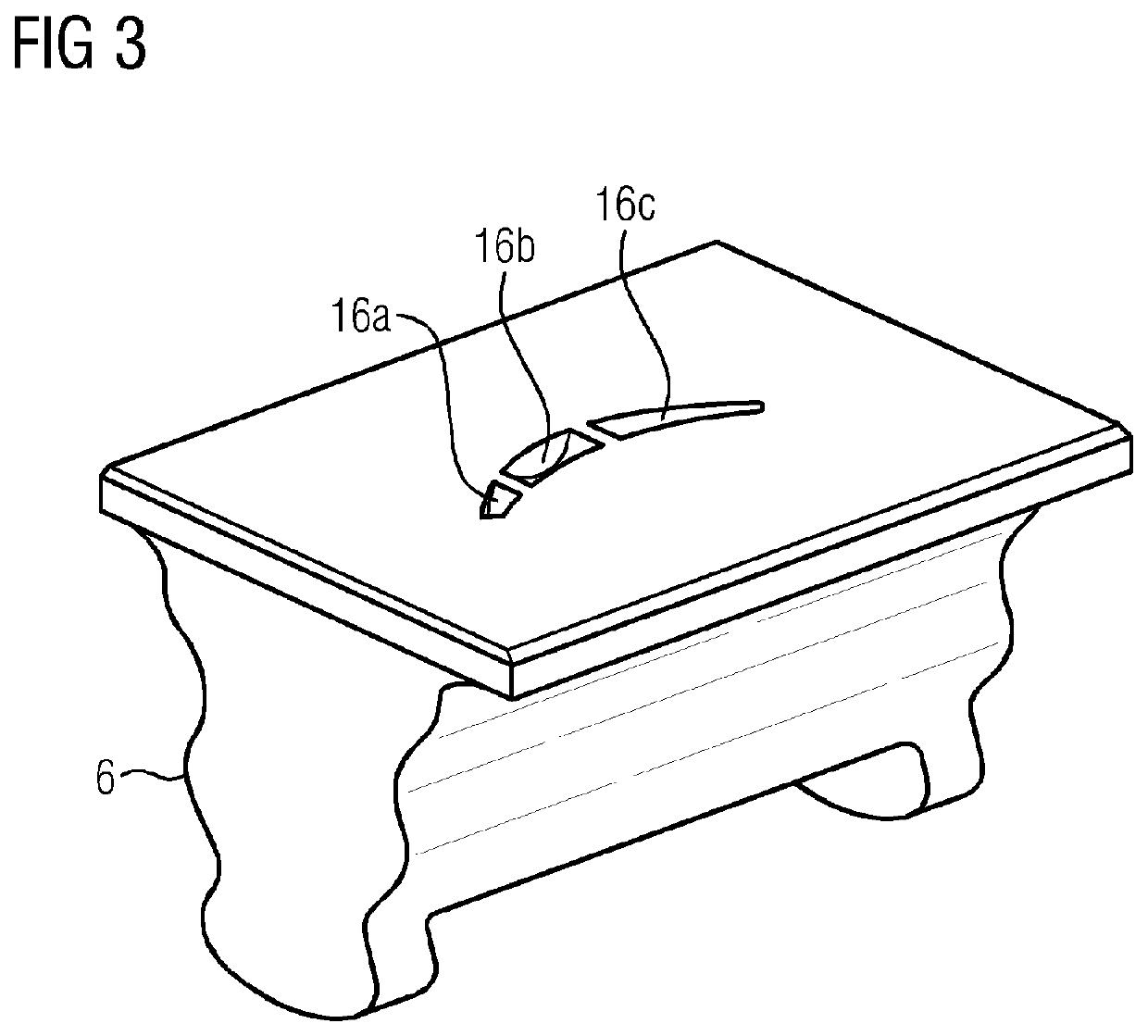

[0026]FIG. 1 shows a turbine blade 2, here a guide blade, which is of two-part construction.

[0027]A first region 4 of the turbine blade 2 is constructed as a cast part and substantially comprises a blade root 6 of the turbine blade 2. This first region 4 is produced in series by means of a process for casting with lost models, in particular by means of precision casting. In precision casting, a wax model in the form of the workpiece to be produced is made for each cast part. In this case, the production of the cast part 4 has been significantly simplified in that the blade root 6 does not have any undercuts. Thus, no ceramic cores are used in the production of the blade root 6.

[0028]A second region 8 of the turbine blade 2 is produced by means of a generative manufacturing process and comprises a blade airfoil 10 and a small part 12 of the blade root 6, said small part adjoining the blade airfoil 10. A

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap