Composite structure of marine navigation device and additive manufacturing method thereof

A technology for maritime navigation and additive manufacturing, which is applied in the direction of manufacturing tools, additive manufacturing, and additive processing. It can solve the problems of long time-consuming electroplating, insignificant anti-collision effects, and unstable painting methods, and achieve light weight. , good toughness and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

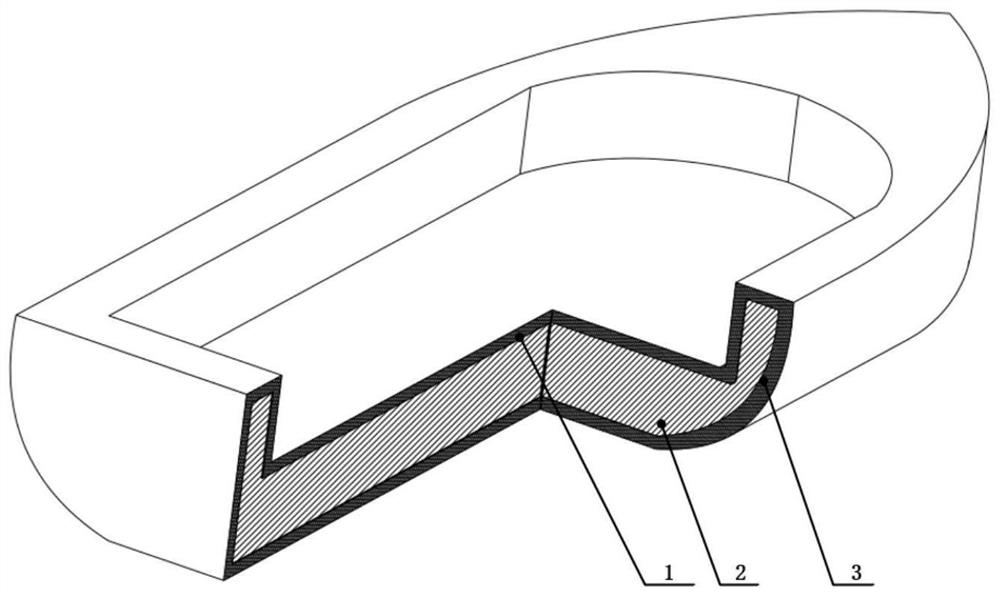

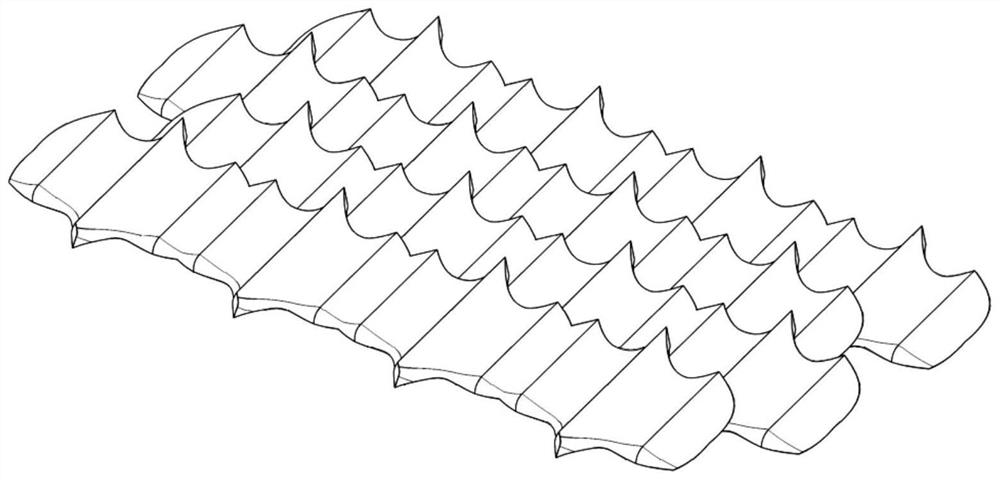

[0060] combine figure 1 The marine navigation device is mainly composed of the marine navigation device base 2, the marine navigation device inner layer 1 and the marine navigation device outer layer 3, the marine navigation device base 2 is placed in the middle, and the marine navigation device inner layer 1 is covered by the marine navigation device base 2. Above, the outer layer 3 of the marine navigation device covers the lower part of the base body 2 of the marine navigation device. The substrate 2 of the marine navigation device is made of aluminum alloy doped with a specific proportion of rare earth elements through coaxial wire-feeding arc additive manufacturing. The substrate 2 of the marine navigation device is a topology-optimized mechanically enhanced structure. The inner layer 1 of the marine navigation device and the outer layer of the marine navigation device 3 is made of glass fiber / ABS composite material, and the skin of the outer layer 3 of the marine navigati

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap