Mold Movement Control Mechanism And Mold Having The Same

a technology of movement control mechanism and mold, which is applied in the field of control mechanism, can solve the problems of spring abrasion, corrosion, fatigue, and design difficulties of molds, and achieve the effects of reducing design and maintenance costs and improving product precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

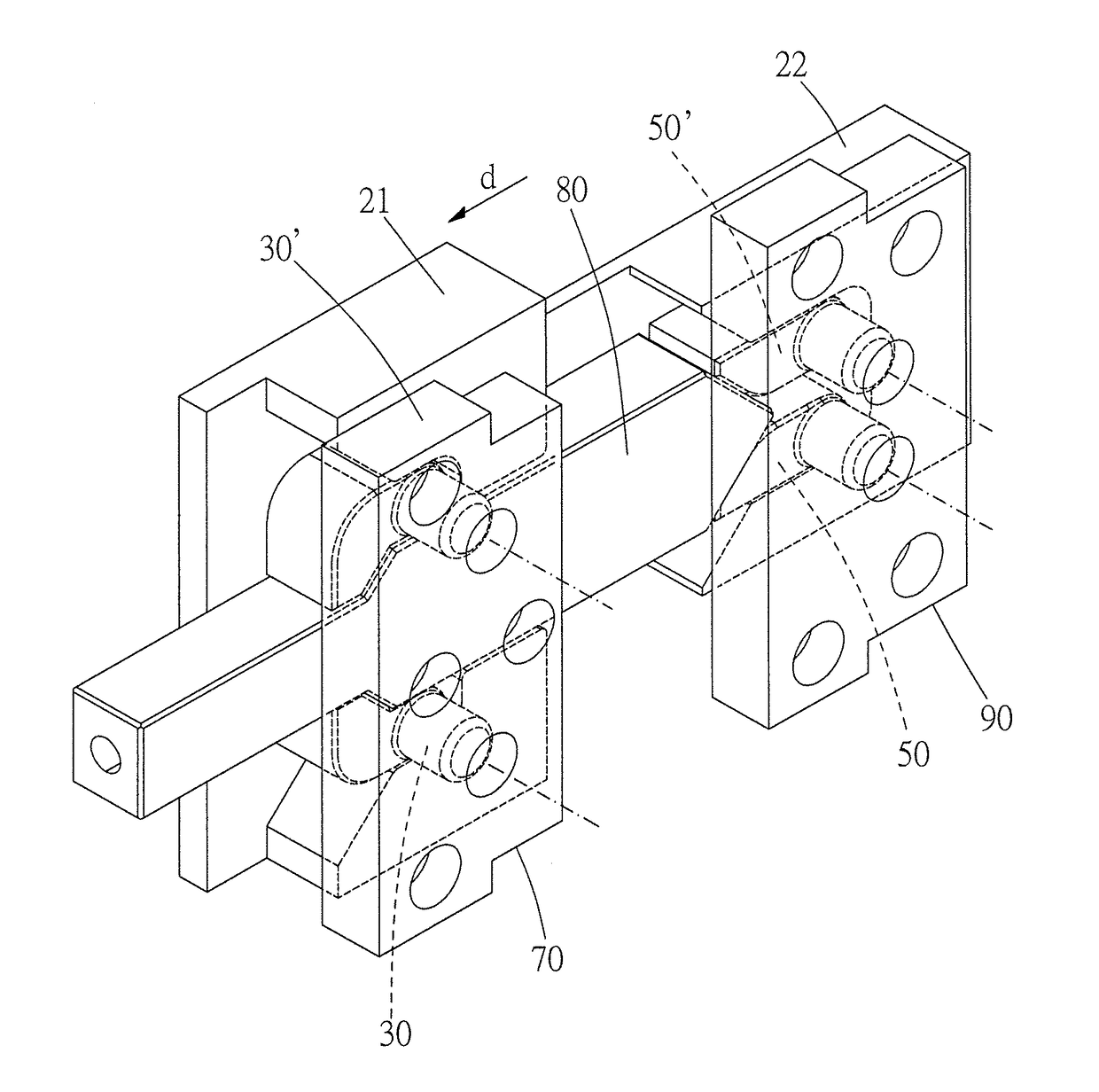

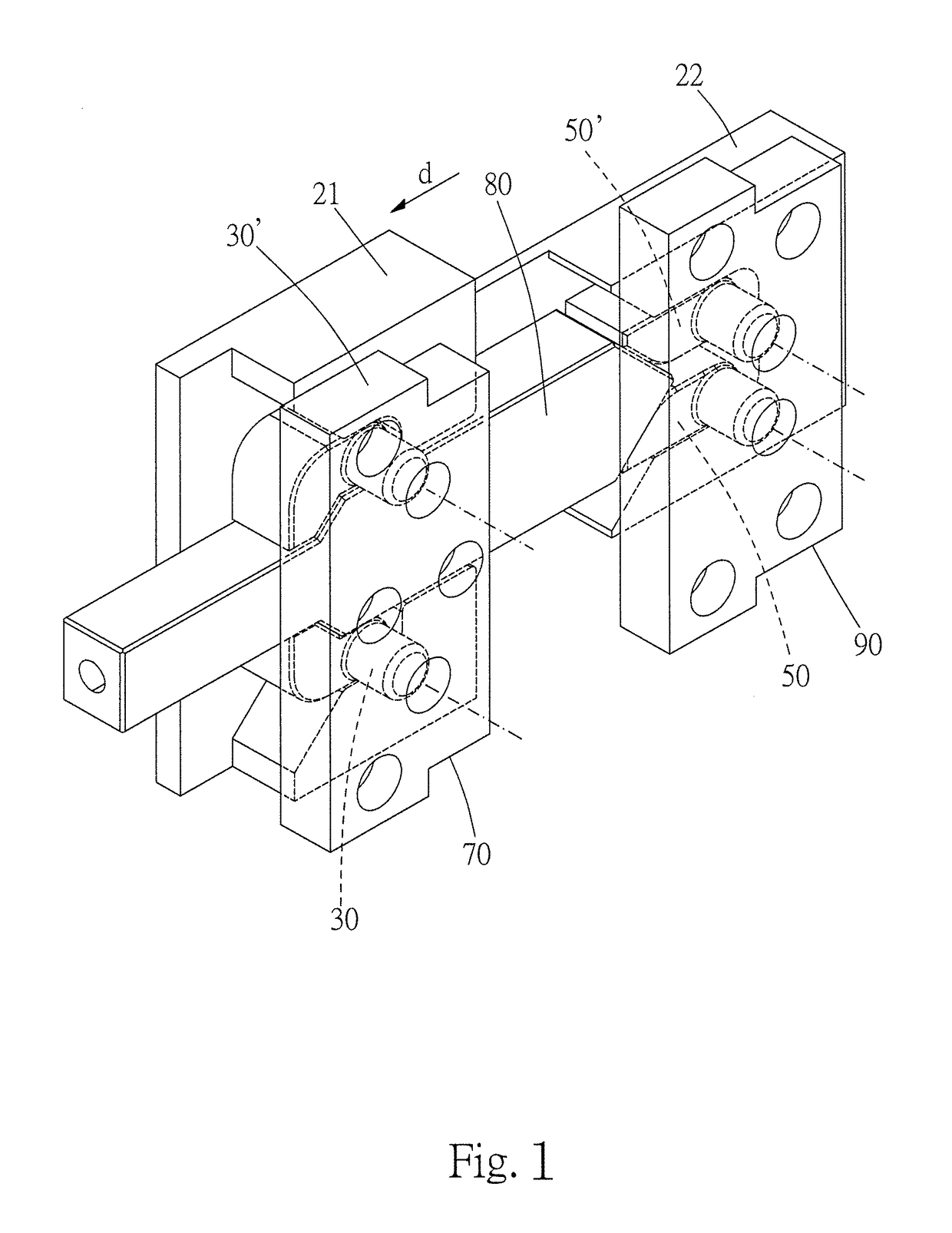

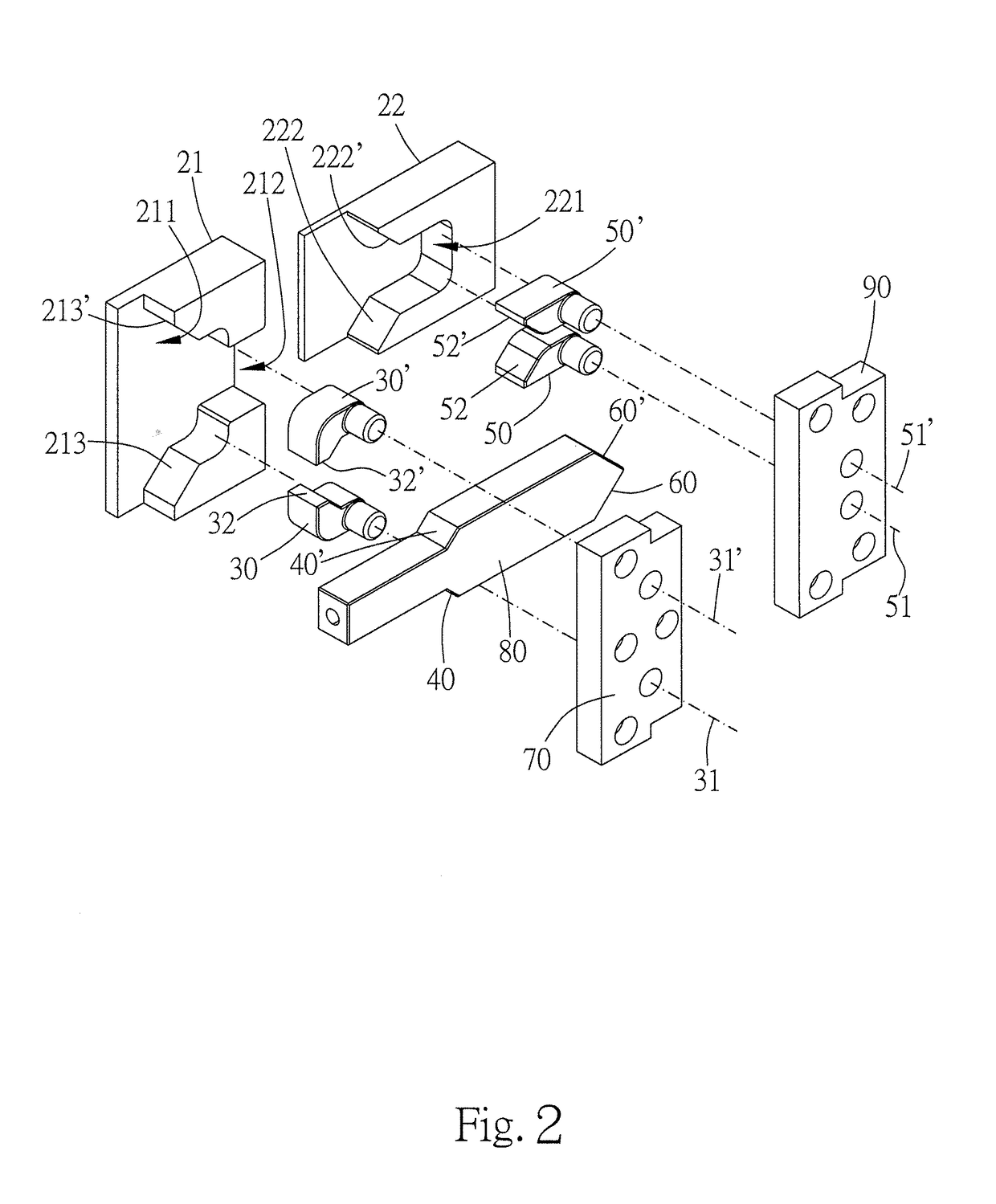

[0015]Please refer to FIG. 1 to FIG. 3 for an embodiment of the present invention. The present embodiment provides a mold movement control mechanism which is usually combined in a mold with a mold module. As shown in FIG. 3, the mold module includes a first plate 11, a second plate 12, and a third plate 13. The plates are components of the mold module which is utilized for molding works or products in manufacturing processes, such as injection molding process. The plates may be formed with cavities which contacts and receives the product directly in manufacturing processes. In other cases, the plates may be designed for carrying and controlling cores which are formed with cavities. Generally, the plates are made with flat appearance. However, the dimensions and the shape of the plates are not limited, adjustable for fitting with products and manufacturing machines. To remove or demould the product, the mold module can opened, closed, or moved by moving the mold module or the plates 11,

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Torque | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap