System and method for measuring the level of fluid in a container

a technology of fluid level and container, applied in the field of system and method for measuring the level of fluid in a container, can solve the problems of inaccurate measurement of many of the probe systems, abnormal electrical resistance path between the probes, and -based monitoring systems providing less accurate and less reliable measurements of black and gray water container levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

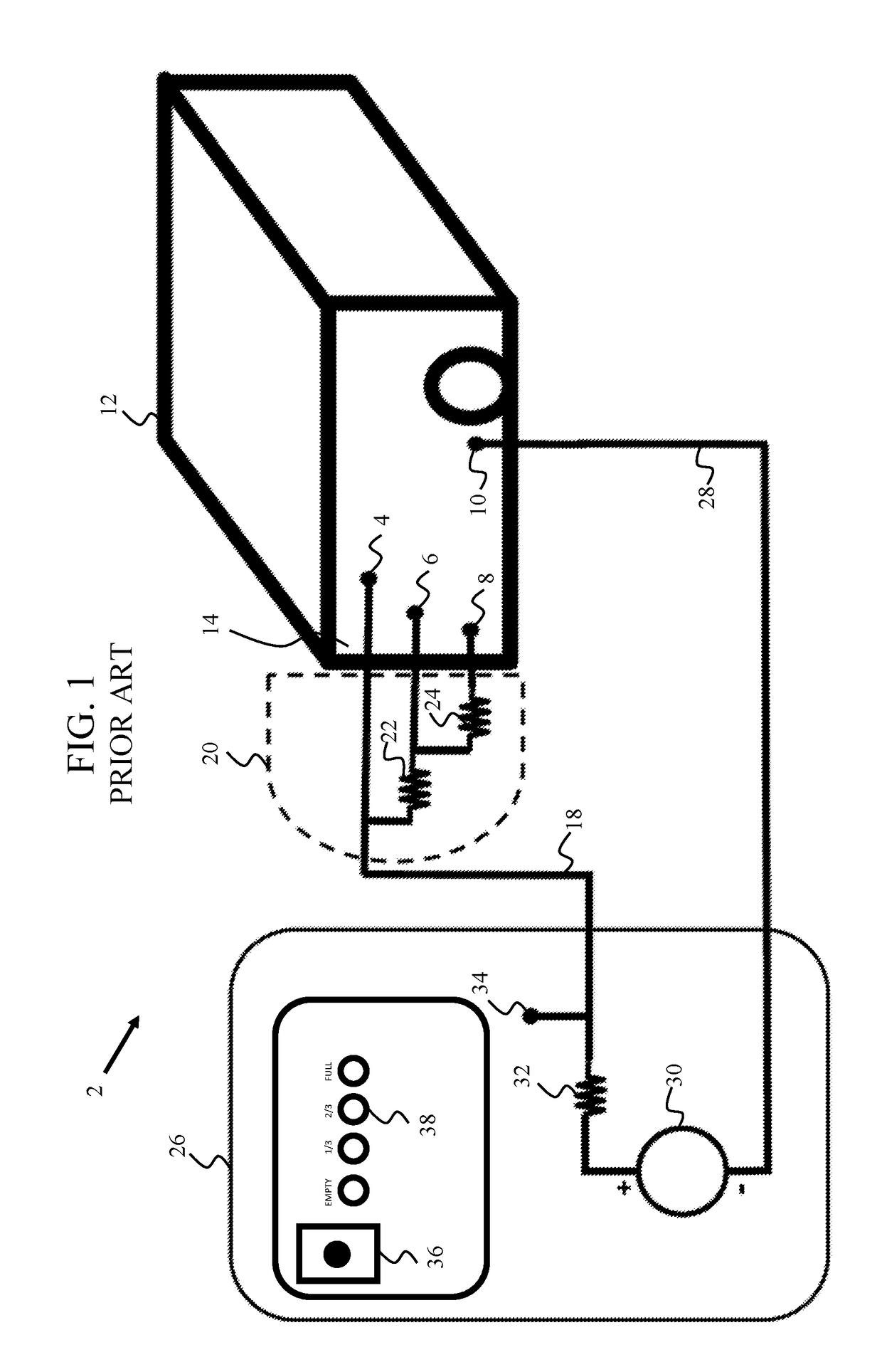

[0021]FIG. 1 is a schematic circuit for a low-cost container monitoring system 2 that utilizes electrical resistance-based probes 4, 6, 8, 10 that are installed through the walls of a fluid container 12 of a recreational vehicle (RV). The electrical resistance-based probes are typically stainless steel and penetrate a plastic, non-conducting container wall 14 at three levels. A ground probe 10 is installed within the container wall at the same level of the lowest probe 8. On the interior of the container (not shown), the probes have a rounded surface with approximately a 1-centimeter diameter exposed to the container contents. On the exterior of the container, the probes can be easily connected to a wire. The three probes that are installed at different levels are connected to each other through a sealed resistor pack 20, containing resistors 22, 24, which connects to a probe wire 18, which in turn connects to a monitor panel 26 located in the living space of the RV. The ground probe 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap