Over fire arrangement and method

a fire arrangement and over fire technology, applied in the direction of combustion types, combustion processes, combustion using lump and pulverulent fuel, etc., can solve the problems of increasing including carbon monoxide, negative effects of nox emissions from combustion processes, and reducing combustion efficiency, so as to improve the burnout rate of fuel, reduce the amount of unburned in the combustion process, and improve the effect of combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

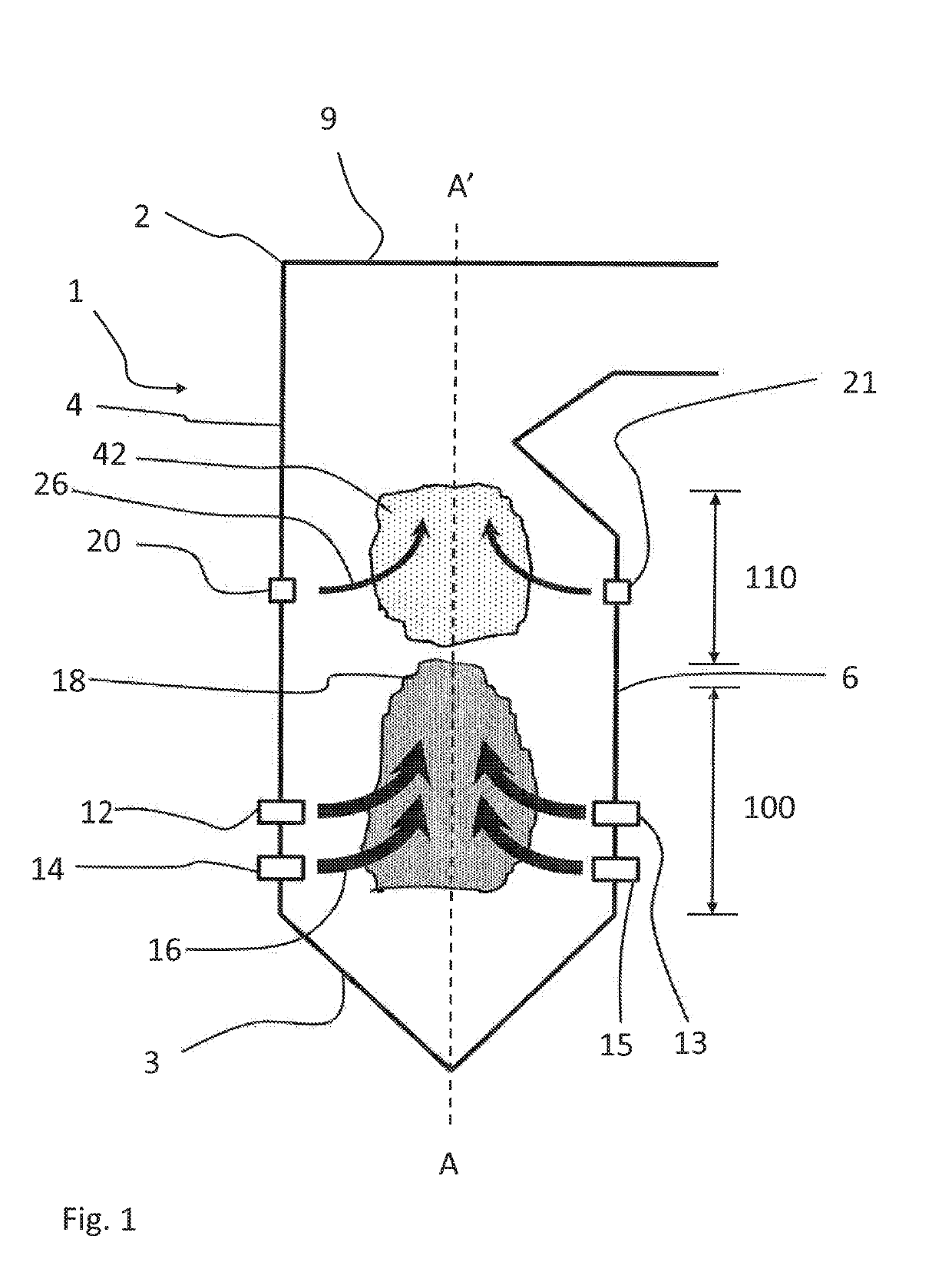

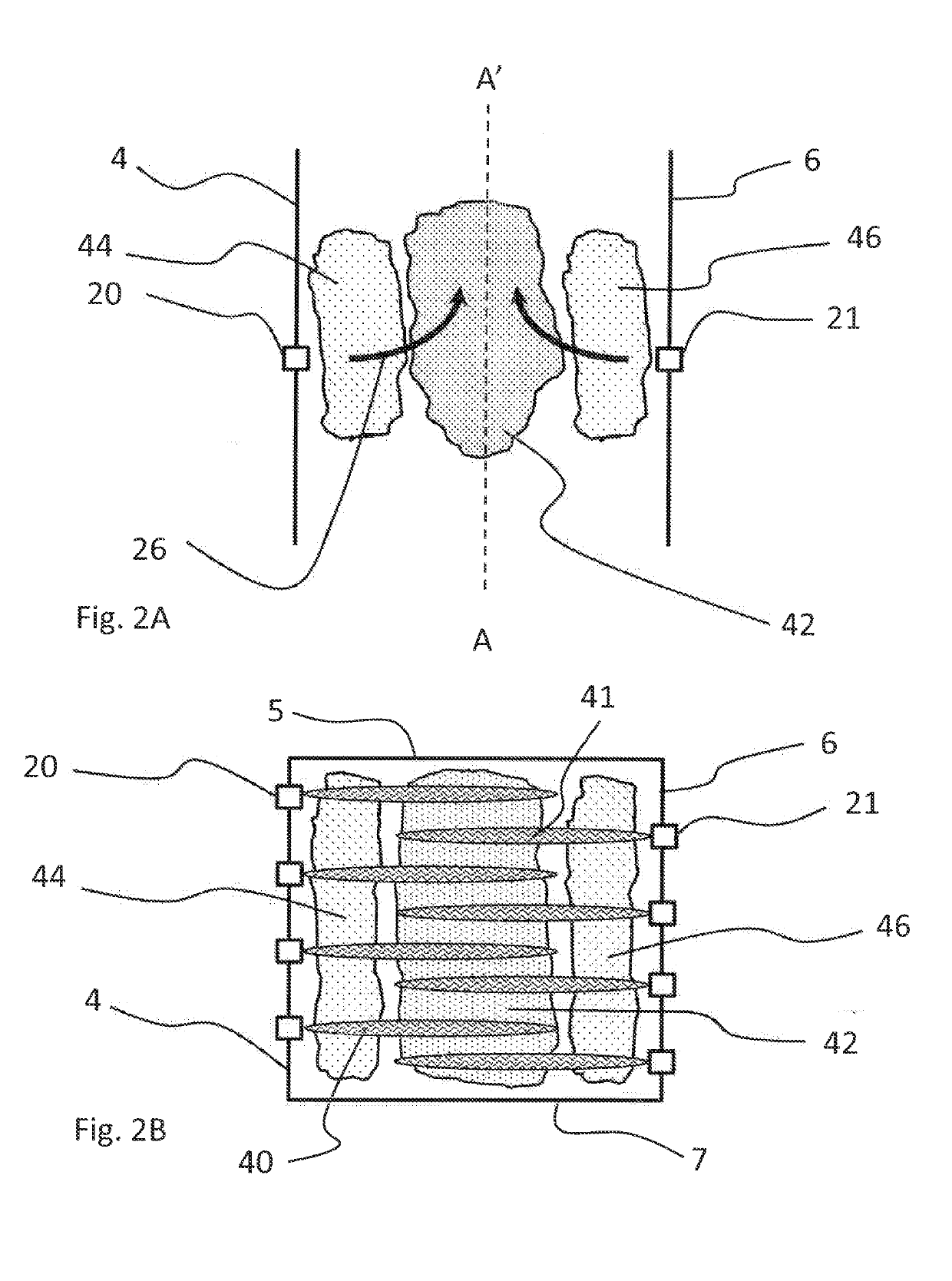

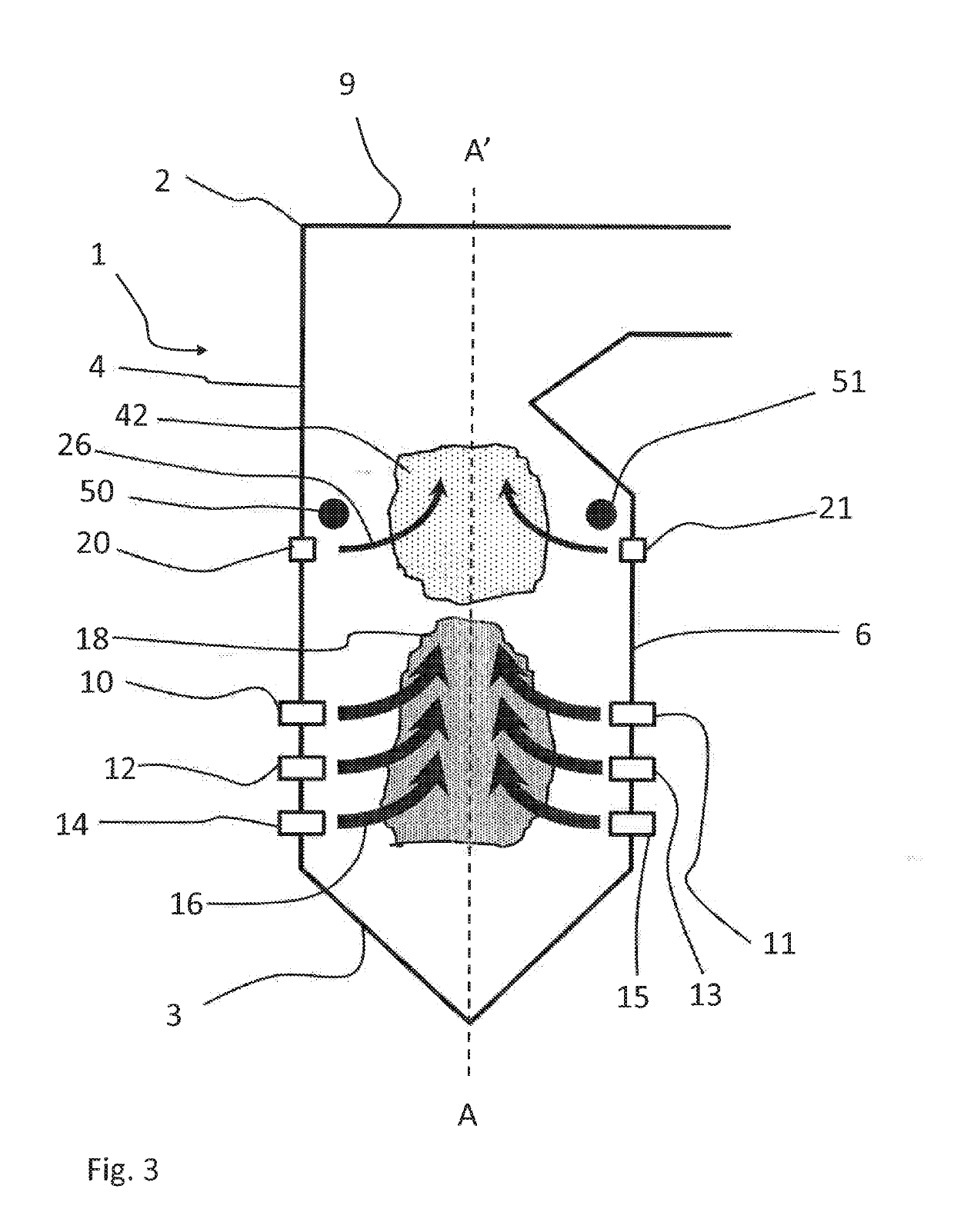

[0028]FIG. 1 shows a prior art furnace 1 having a bottom 3 and top 9, and opposing front wall 4 and rear wall 6 as well as opposing first and second side wall 5, 7 (shown in FIG. 2B). The front wall 4 and rear wall 6 as well as opposing first and second side wall 5, 7 form together an enclosure 2 of the furnace 1, as shown in FIG. 2B. The furnace 1 comprises burners 14, 12, 10, 15, 13, 11 provided to the opposing first and second walls 4, 6 of the furnace for combusting fuel. In this embodiment the furnace comprises at least one first primary burner 14 provided to the first wall 4 and at least one second primary burner 15 provided to the second wall 6 for forming a first level of burners and first combustion stage. The furnace 1 further comprises at least one first secondary burner 14 provided to the first wall 4 and at least one second secondary burner 15 provided to the second wall 6, the secondary burners being arranged above the primary burners 14, 15 in vertical direction for stag

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap