Direct burial ground lug/ connector

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

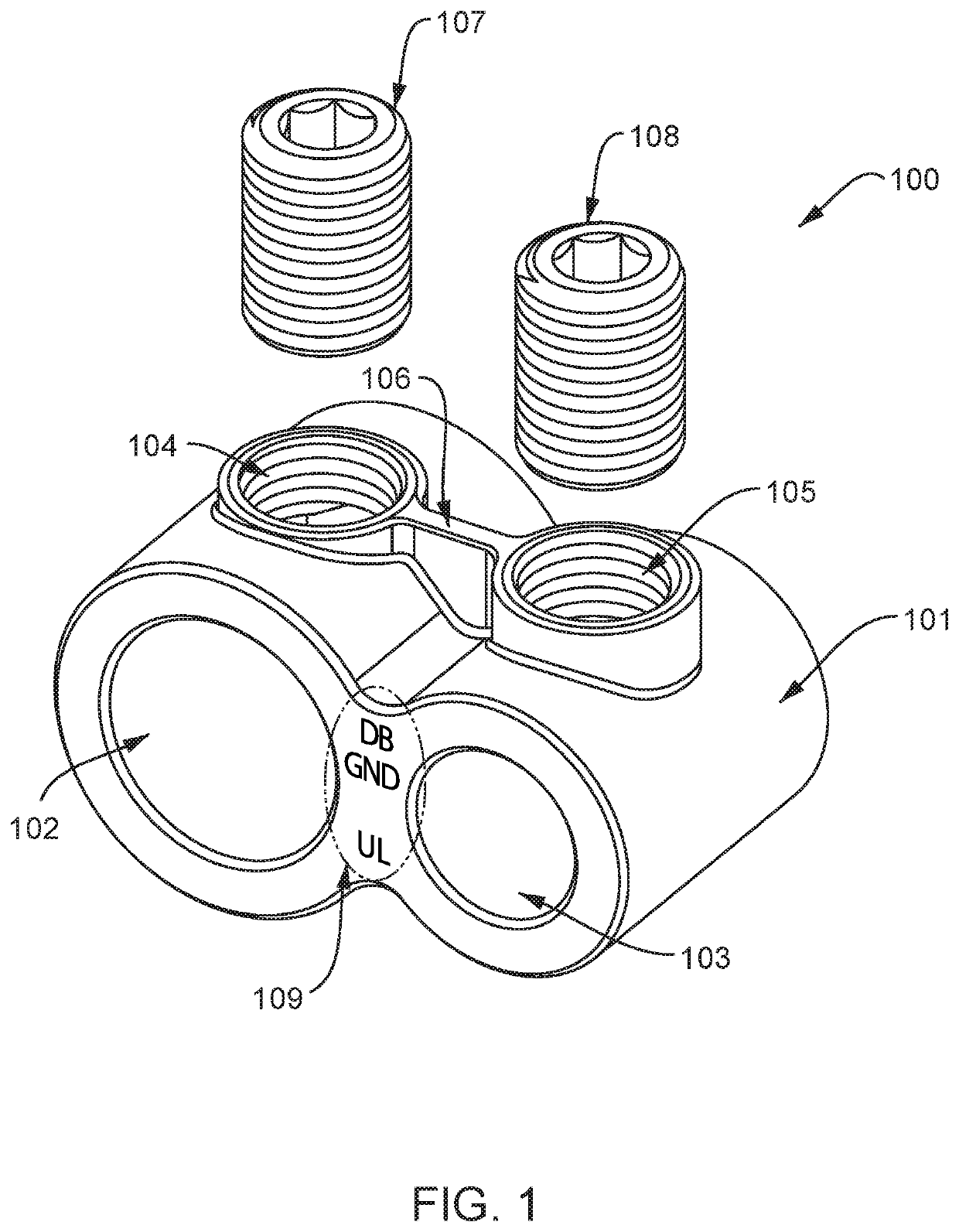

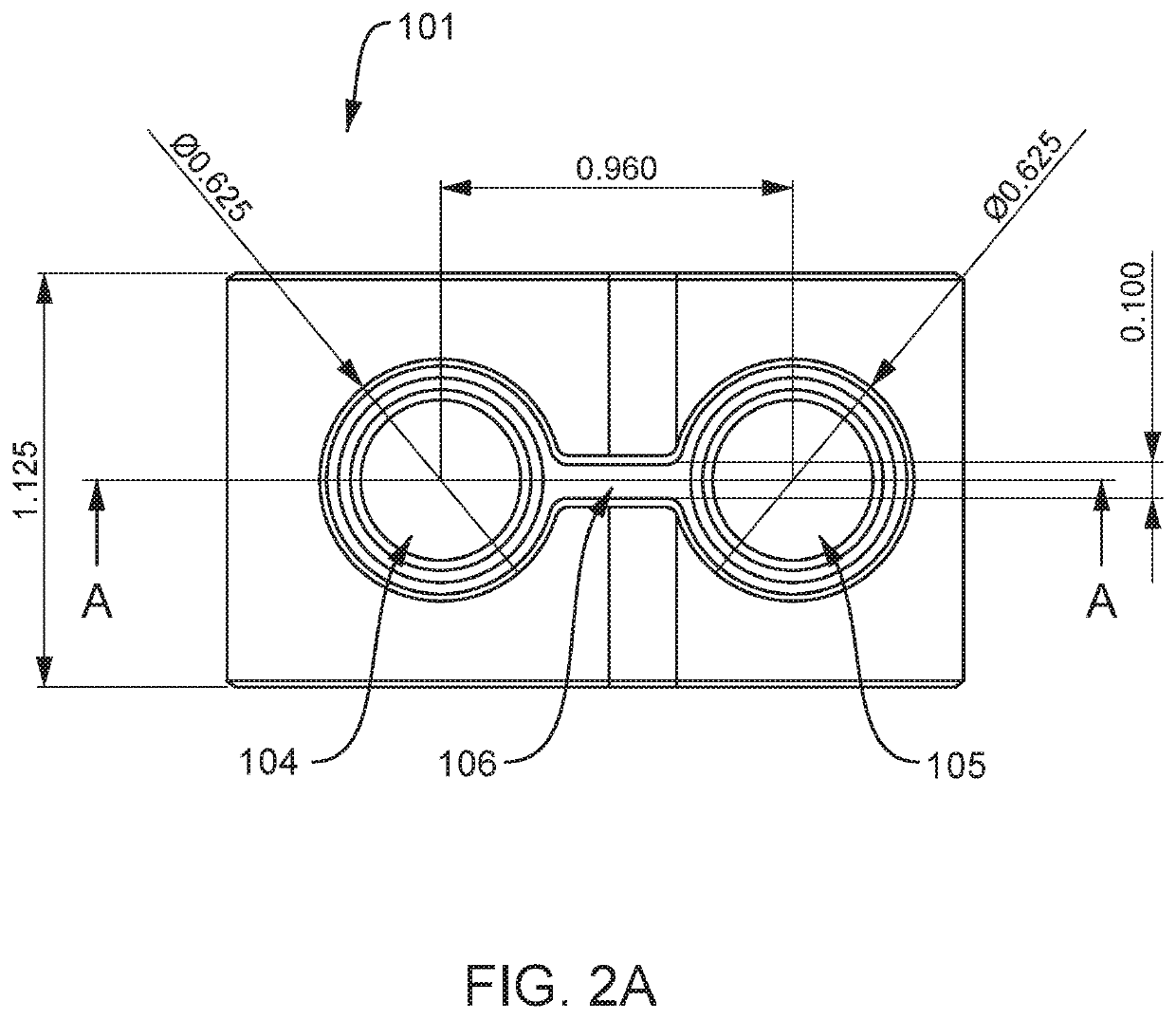

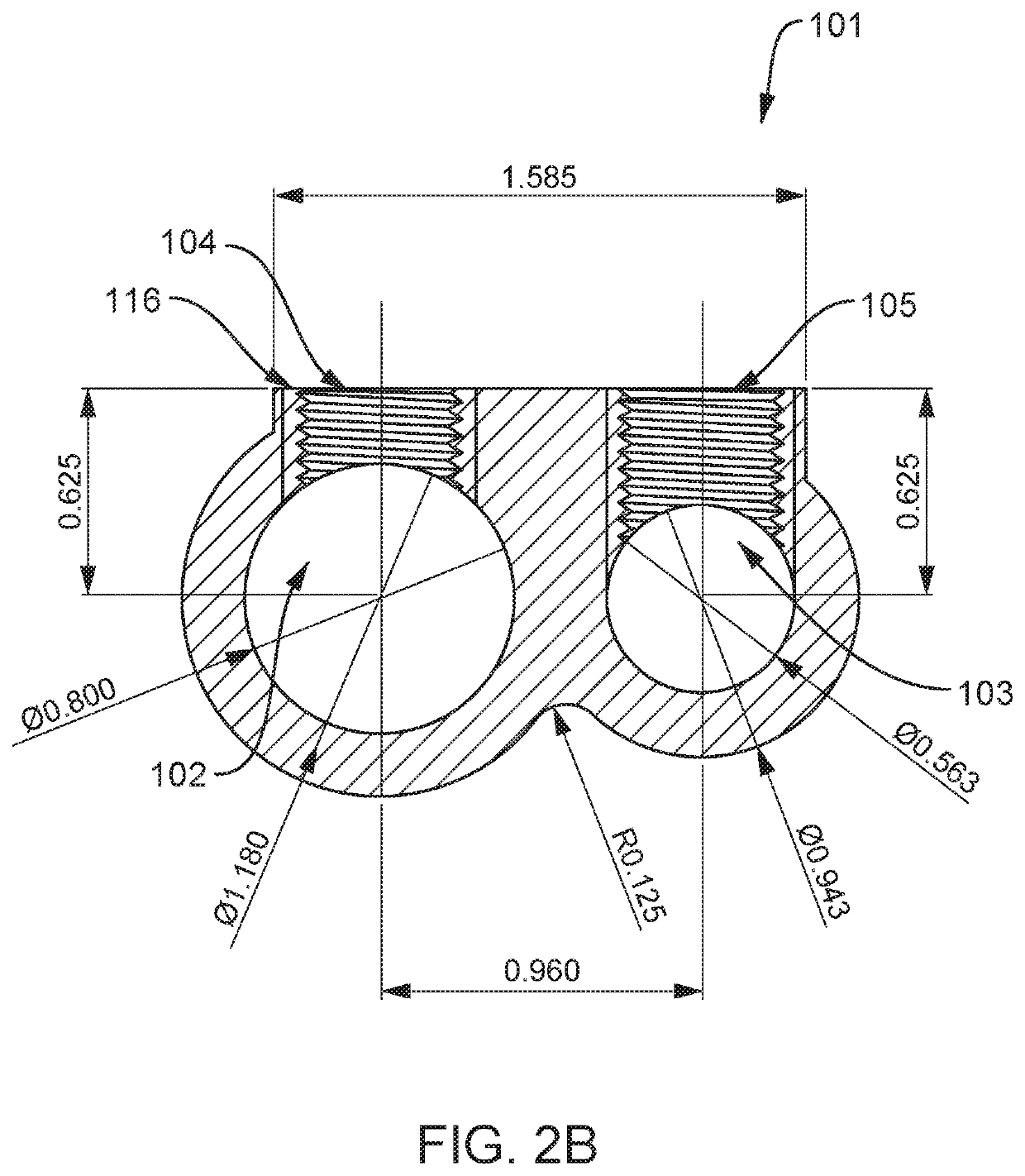

[0017]Reference will now be made in detail to specific embodiments of the present invention. Examples of these embodiments are illustrated in the accompanying drawings. Numerous specific details are set forth in order to provide a thorough understanding of the present invention. While the embodiments will be described in conjunction with the drawings, it will be understood that the following description is not intended to limit the present invention to any one embodiment. On the contrary, the following description is intended to cover alternatives, modifications, and equivalents as may be included within the spirit and scope of the appended claims. Numerous specific details are set forth in order to provide a thorough understanding of the present invention.

[0018]A key feature of the disclosed embodiments is the direct burial ground lug that does not require the use of special tools or instruments. One tool for installation of the rod and conductor may be used. The direct burial ground

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap