Noise reduction method

a cryogenic cooling and noise reduction technology, applied in the direction of gas cycle refrigeration machines, refrigeration machines, refrigeration safety arrangements, etc., can solve the problems of noise monitoring, previously considered undesirable, source of noise in highly sensitive experiments and procedures, etc., and achieve the effect of reducing noise and reducing the amplitude of said vibrations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]We now describe an example of a noise reduction method, along with a description of an example cryogenic cooling system including an example frequency adjuster.

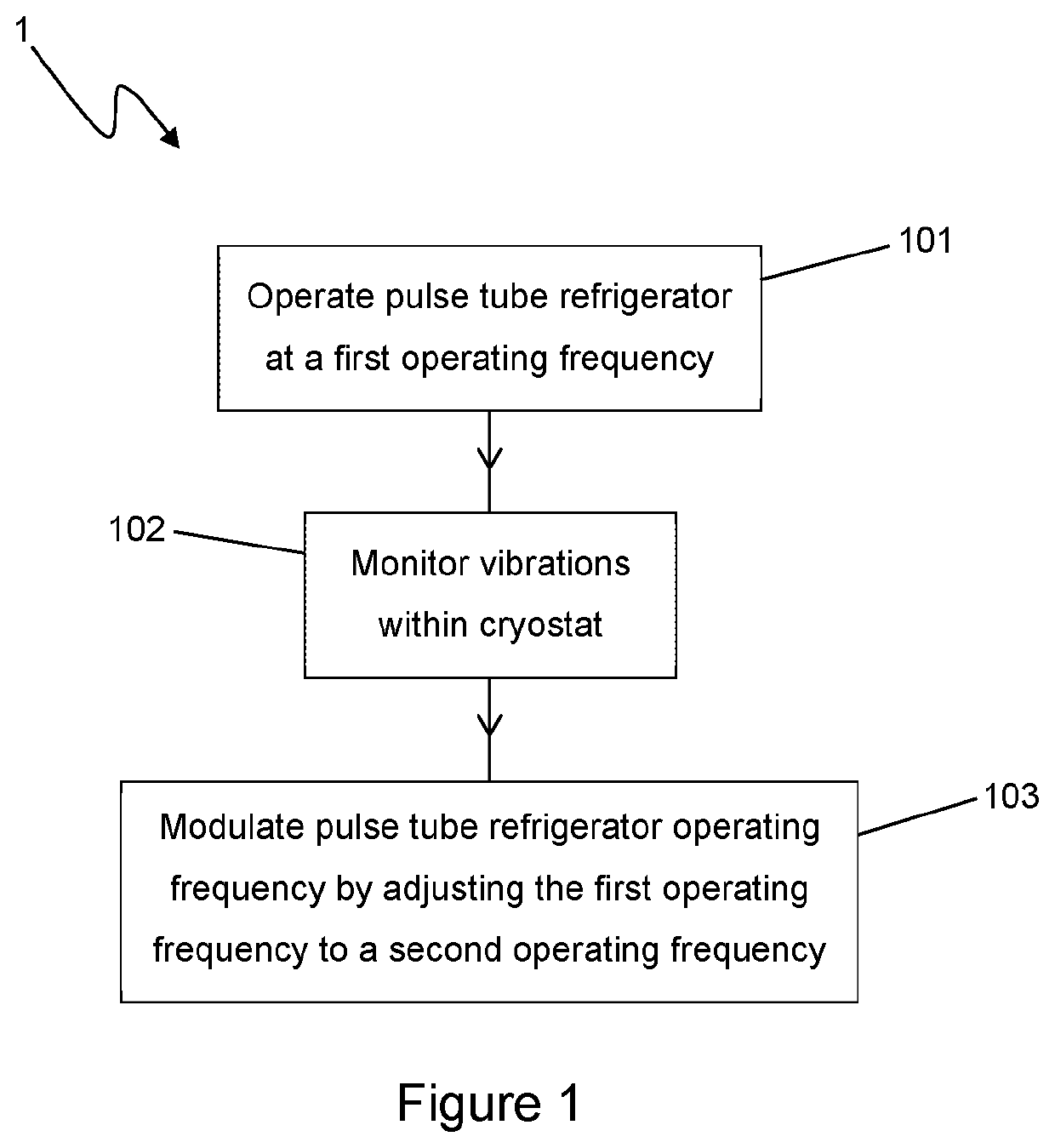

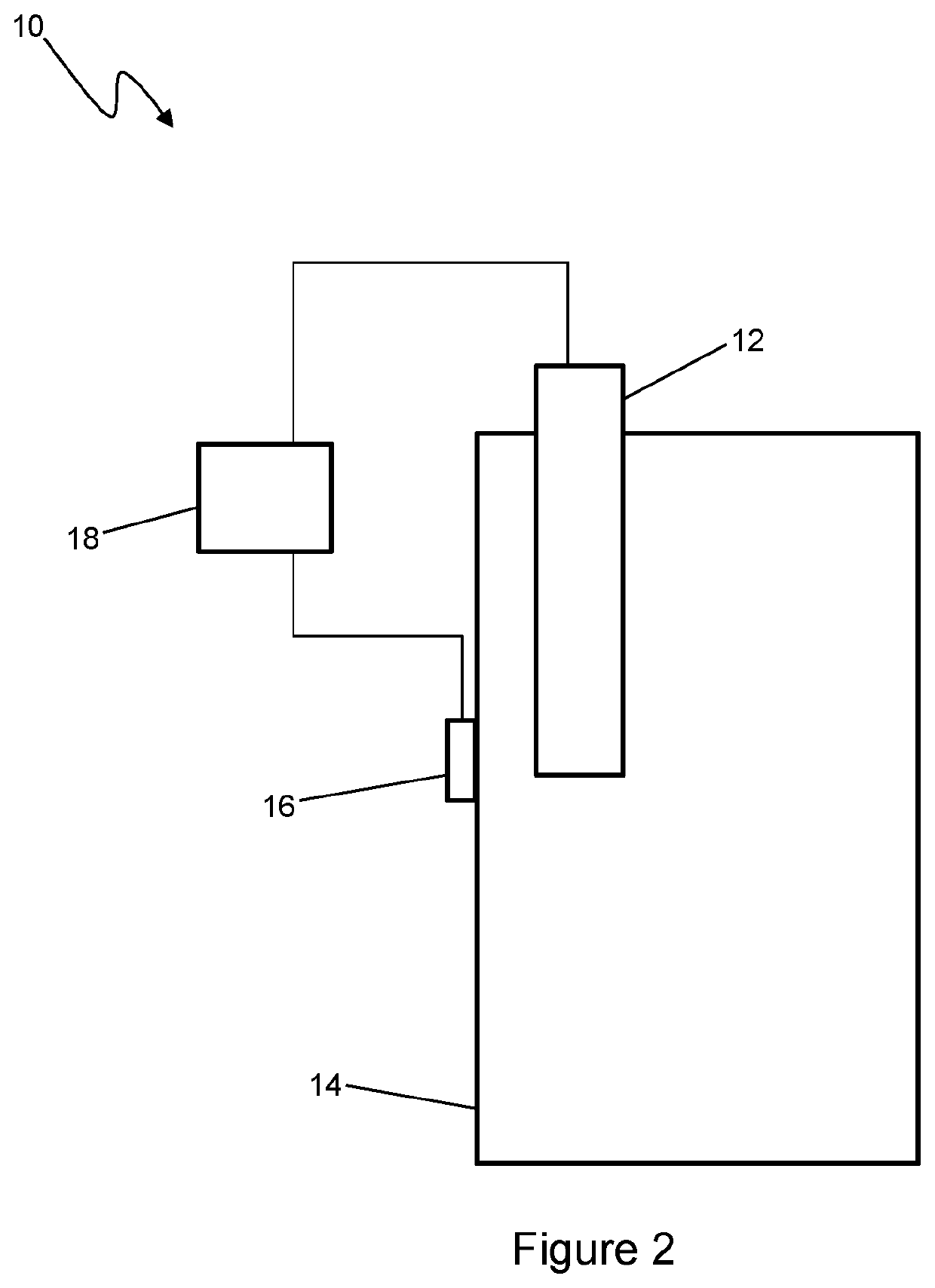

[0043]Referring now to FIG. 1 and FIG. 2, a process of a first example noise reduction method is illustrated generally at 1 in FIG. 1 and an example cryogenic cooling system is illustrated generally at 10 in FIG. 2.

[0044]In the cryogenic cooling system 10, a pulse tube refrigerator (PTR) 12 is coupled to a cryostat 14. The cryostat is typically mounted in a support frame (not shown). An accelerometer 16 is in contact with the cryostat and is connected to a controller 18 to which the accelerometer outputs data. The accelerometer and the controller make up the frequency adjuster.

[0045]At step 101, the PTR 12 is operated at a first operating frequency. This is achieved by operating a rotary valve (not shown) in the PTR at the first operating frequency. Additionally, the PTR typically has external components coupled to it. An

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap