Separation membrane

a separation membrane and membrane technology, applied in the field of separation membranes, can solve the problems of difficult to obtain sufficient gas separation performance and leakage of gas to be separated, and achieve the effect of maintaining stable high separation performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0112]Polyacrylonitrile (MW: 150,000) manufactured by Polysciences, Inc., polyvinylpyrrolidone (MW: 40,000) manufactured by Sigma-Aldrich Co. LLC., and, as a solvent, dimethyl sulfoxide (DMSO) manufactured by WAKENYAKU CO., LTD. were charged into a separable flask, and the mixture was stirred and refluxed to prepare a homogeneous, transparent solution. In this process, the concentrations of polyacrylonitrile and polyvinylpyrrolidone were both 11.5% by weight.

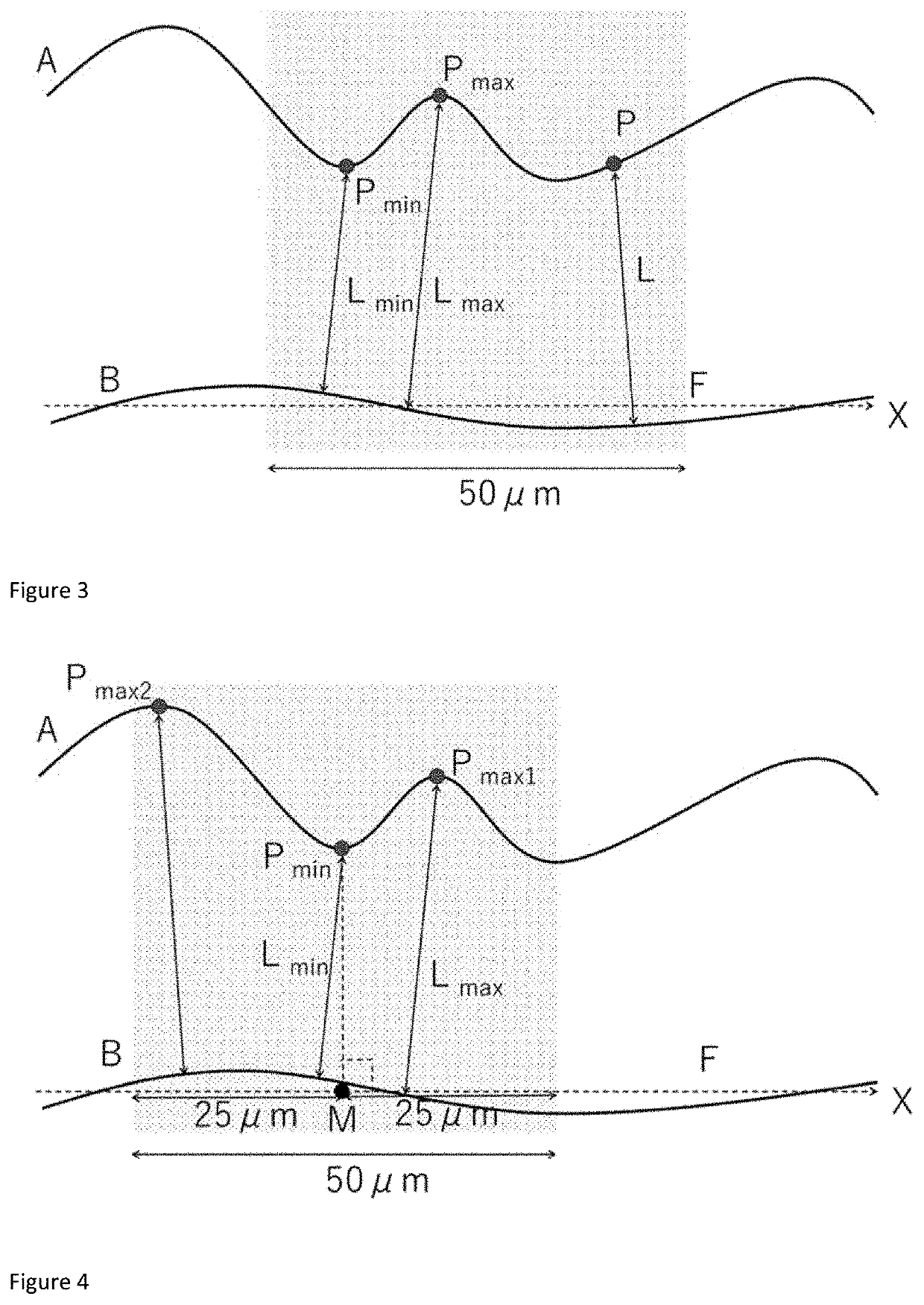

[0113]Using the obtained coating stock solution, a film was formed on the surface of a porous carbon core having a hollow fiber-shaped co-continuous porous structure by a nozzle coating method. The resulting product was infusibilized by heating at 240° C. in an oxygen atmosphere. Then, the product was subjected to a carbonization treatment by heating at 600° C. in a nitrogen atmosphere to form a separation layer including a dense carbon layer, whereby a separation membrane was obtained. The co-continuous porous structure of the cor

example 2

[0117]Particles were again adhered to the hollow fiber carbon membrane for separation obtained in Example 1 by the same method as in Example 1.

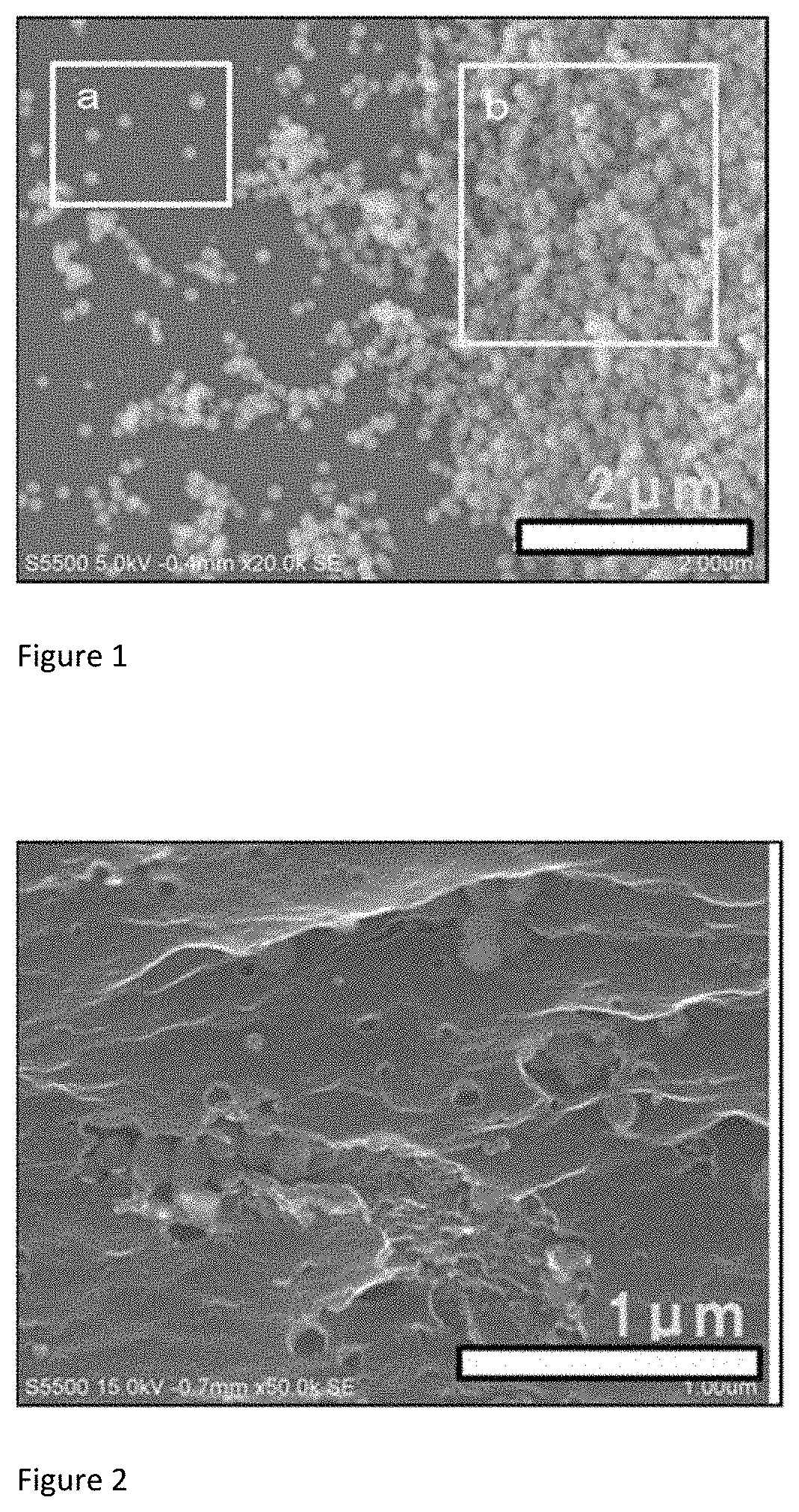

[0118]The following matters were recognized by the observation with the scanning electron microscope: particles adhere to a surface of the dense carbon layer, a dense layer carbon layer has a recess, and at least part of the particles are embedded in the recess.

[0119]The occupancy of the dense carbon layer by the particles was 45%, and the particle size of the adhered particles was 93 nm, which was 1 / 3559 of the average diameter of the separation membrane. The separation factor of the obtained separation membrane was evaluated to be 1.44.

example 3

[0120]To the separation membrane before adhesion of particles produced in Example 1, particles were adhered using a slurry containing two types of particles (SNOWTEX ZL manufactured by Nissan Chemical Corporation and ST-30L manufactured by Nissan Chemical Corporation) dispersed therein by the same method as in Example 1.

[0121]The following matters were recognized by the observation with the scanning electron microscope: particles adhere to a surface of the dense carbon layer, a dense layer carbon layer has a recess, and at least part of the particles are embedded in the recess.

[0122]The occupancy of the dense carbon layer by the particles was 30%, and the particle sizes of the adhered particles were 44 nm and 93 nm, which were 1 / 7523 and 1 / 3559 of the average diameter of the separation membrane, respectively. The separation factor of the obtained separation membrane was evaluated to be 1.08.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap