In2O3 hollow nanosphere coated by nitrogen and sulfur doped carbon layer and preparation method of the In2O3 hollow nanosphere

A hollow nano, sulfur element technology, applied in chemical instruments and methods, gallium/indium/thallium compounds, inorganic chemistry, etc., to achieve the effect of uniform morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] A nitrogen, sulfur element doped carbon layer wrapped In 2 o 3 The preparation method of hollow nanosphere comprises the following steps:

[0027] (1) Preparation of precursors: Dissolve indium nitrate tetrahydrate (0.078g), 2,5-pyridinedicarboxylic acid (0.03g) and 2,1,3-benzisothiazol-3-one (0.02g) In 10mL of N,N-dimethylformamide and water mixed solution with a volume ratio of 6:4, the above solution was ultrasonically dispersed for 10min, and then the mixed solution was transferred to a 50mL polytetrafluoroethylene reactor and heated to 120°C, reaction time 6h. The product was collected by centrifugation, and then washed several times with industrial alcohol to obtain the precursor In(OH)(2,5-PDC), which was dried for use.

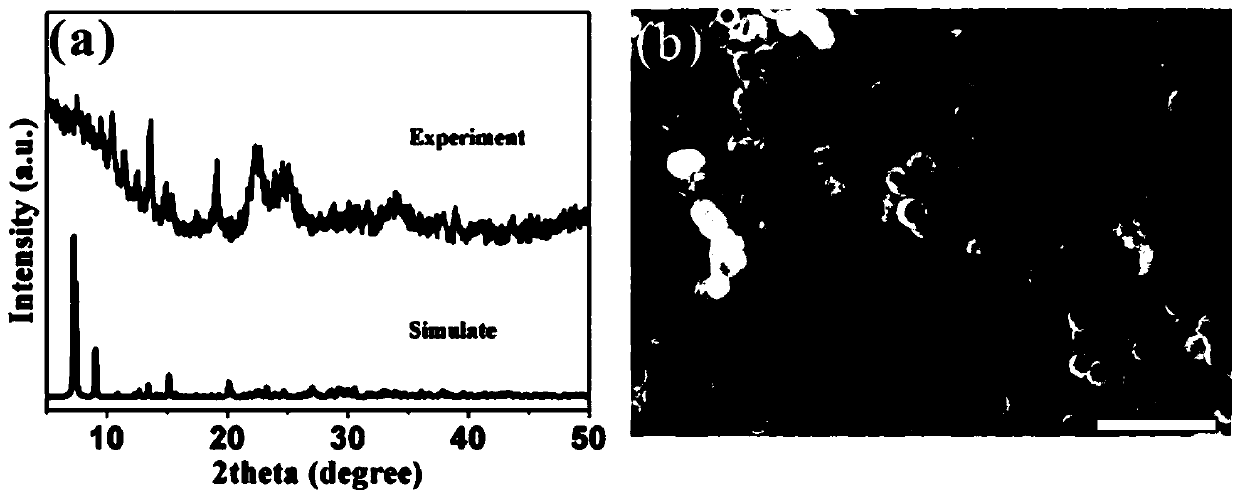

[0028] figure 1 Shown is the XRD of the precursor In(OH)(2,5-PDC) ( figure 1 a) and SEM images ( figure 1 b), SEM image shows that hollow nanospheres with uniform size are successfully synthesized, and XRD proves that the synthesized substanc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap