Light source for an image-generating unit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

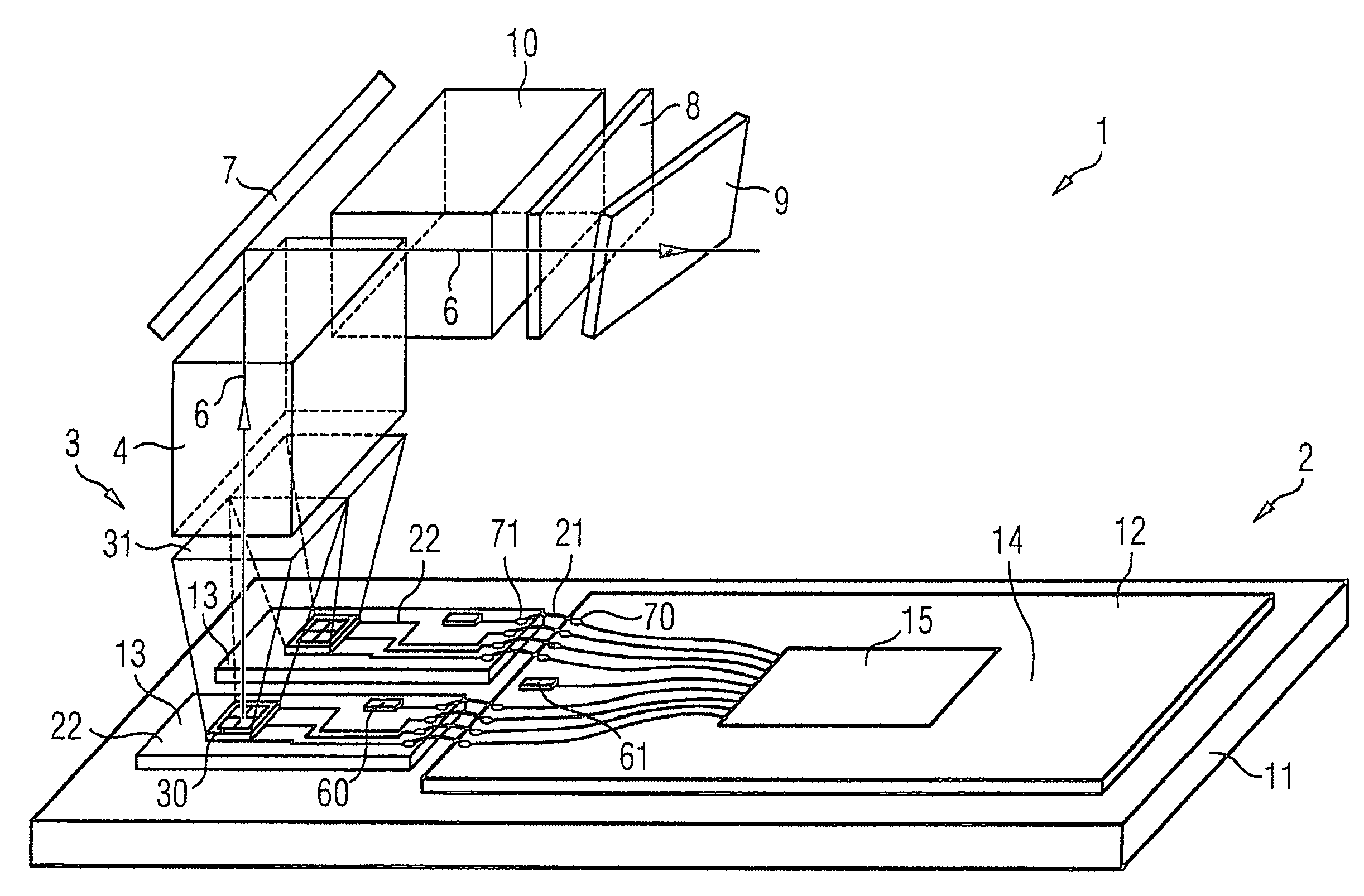

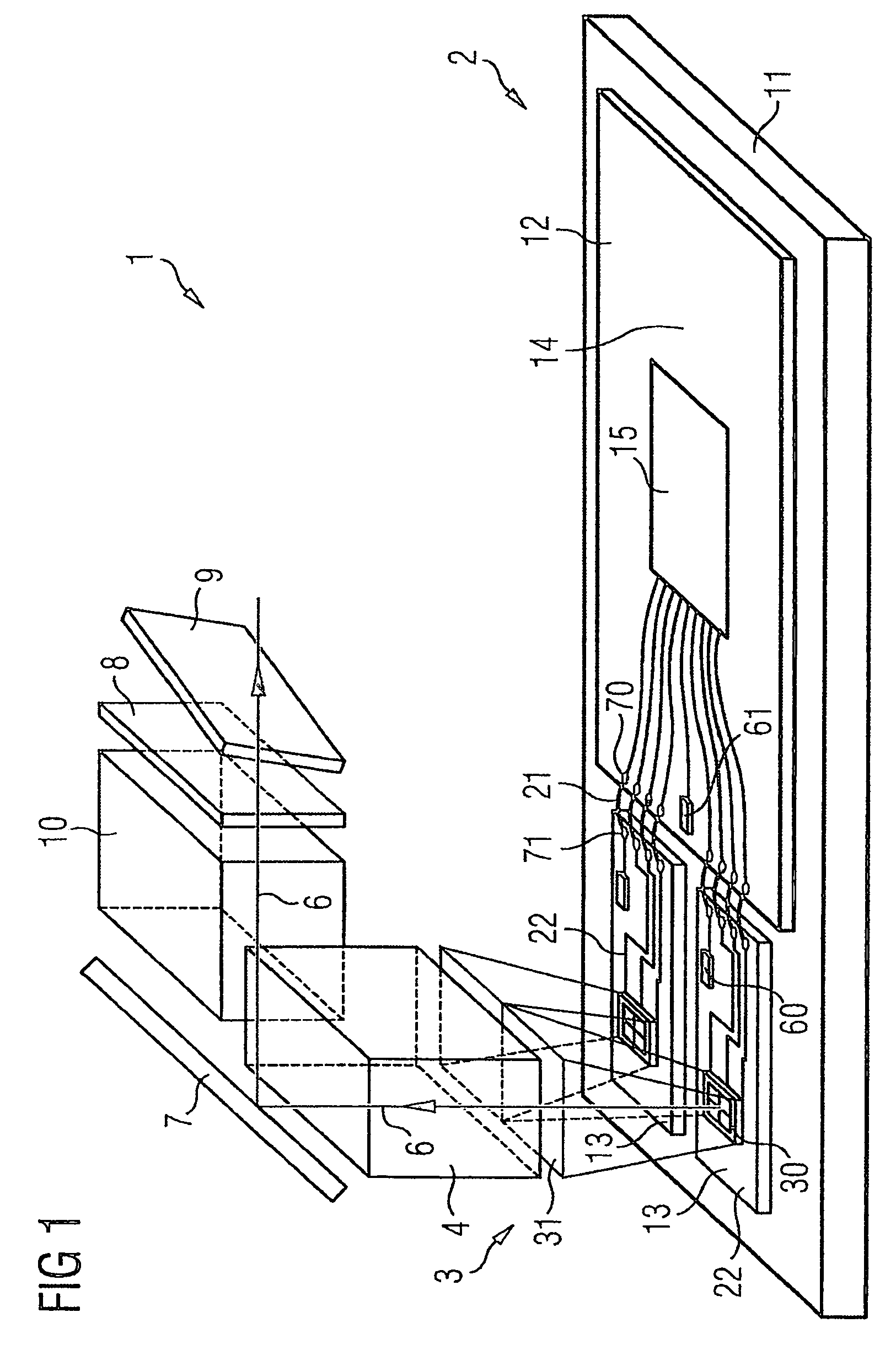

[0031]FIG. 1 shows an image-production unit 1 according to the invention with the major components following the beam path 5 originating from the light source 2, in a main light propagation direction 6: the light source 2, the secondary optics 3, the light-mixing module 4, the mirror 7, the scattering disk 8 and the display 9, in which case a light box 10 can also optionally be arranged between the mirror 7 and the scattering disk 8, in the manner illustrated here.

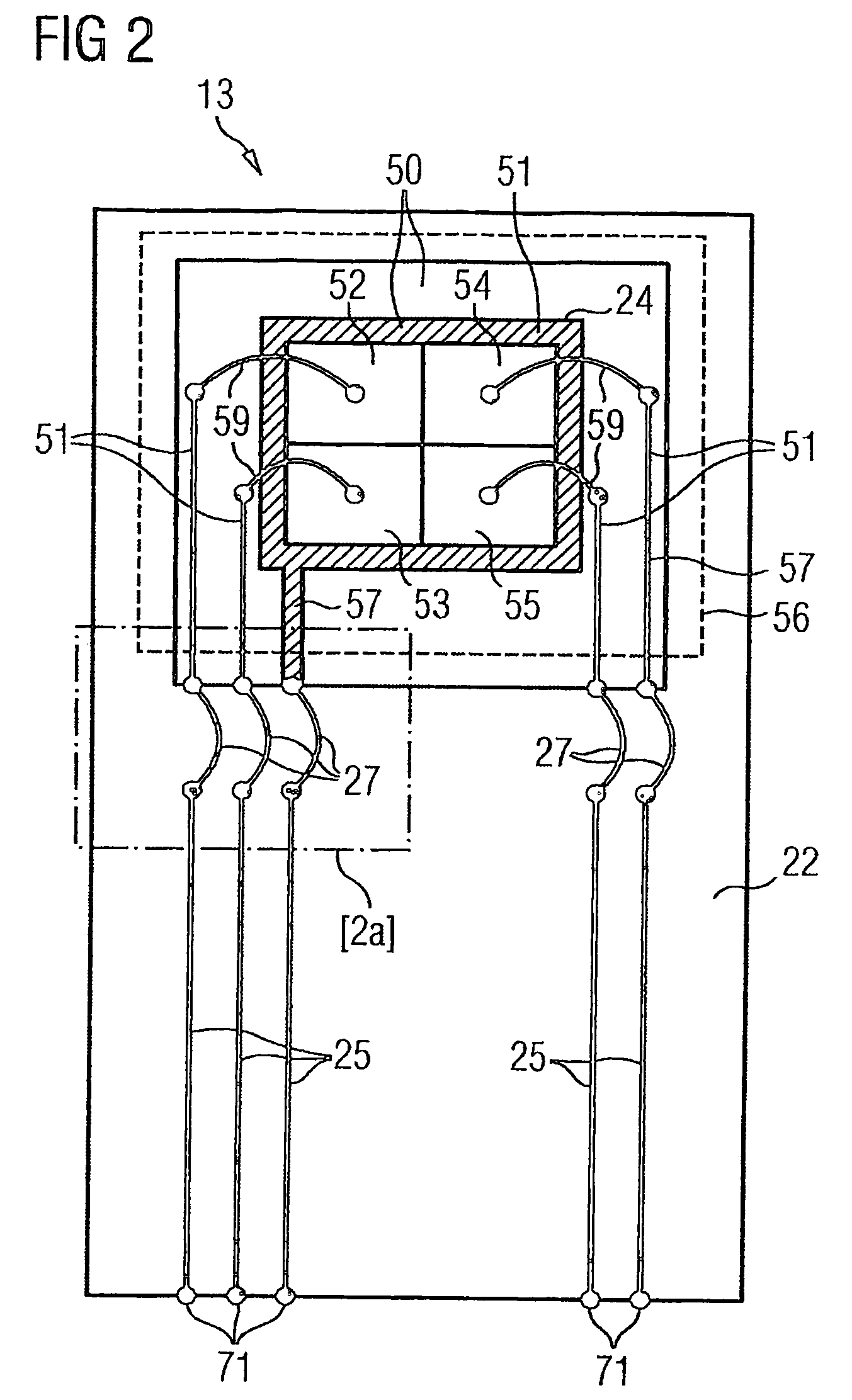

[0032]The light source 2 essentially comprises a mount 11, a drive module 12 and light modules 13. The mount 11 is in the form of a heat sink composed of aluminum, on which the drive module 12 and the light modules 13 are adhesively bonded, by an unpopulated flat face. In this case, the adhesive bonding in each case satisfies stringent demands for thermal conductivity and temperature resistance. The drive module 12 has a second mount element 14, which is in the form of a printed circuit board and is fitted with drive electron

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap