Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Composite ceramic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

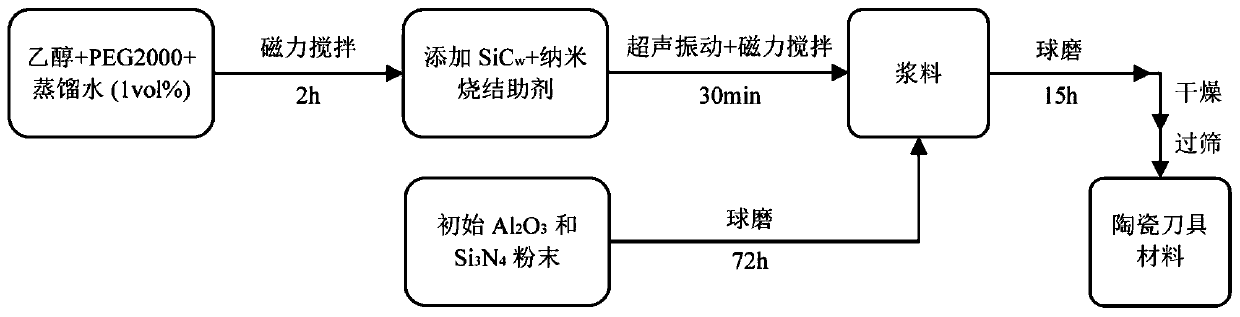

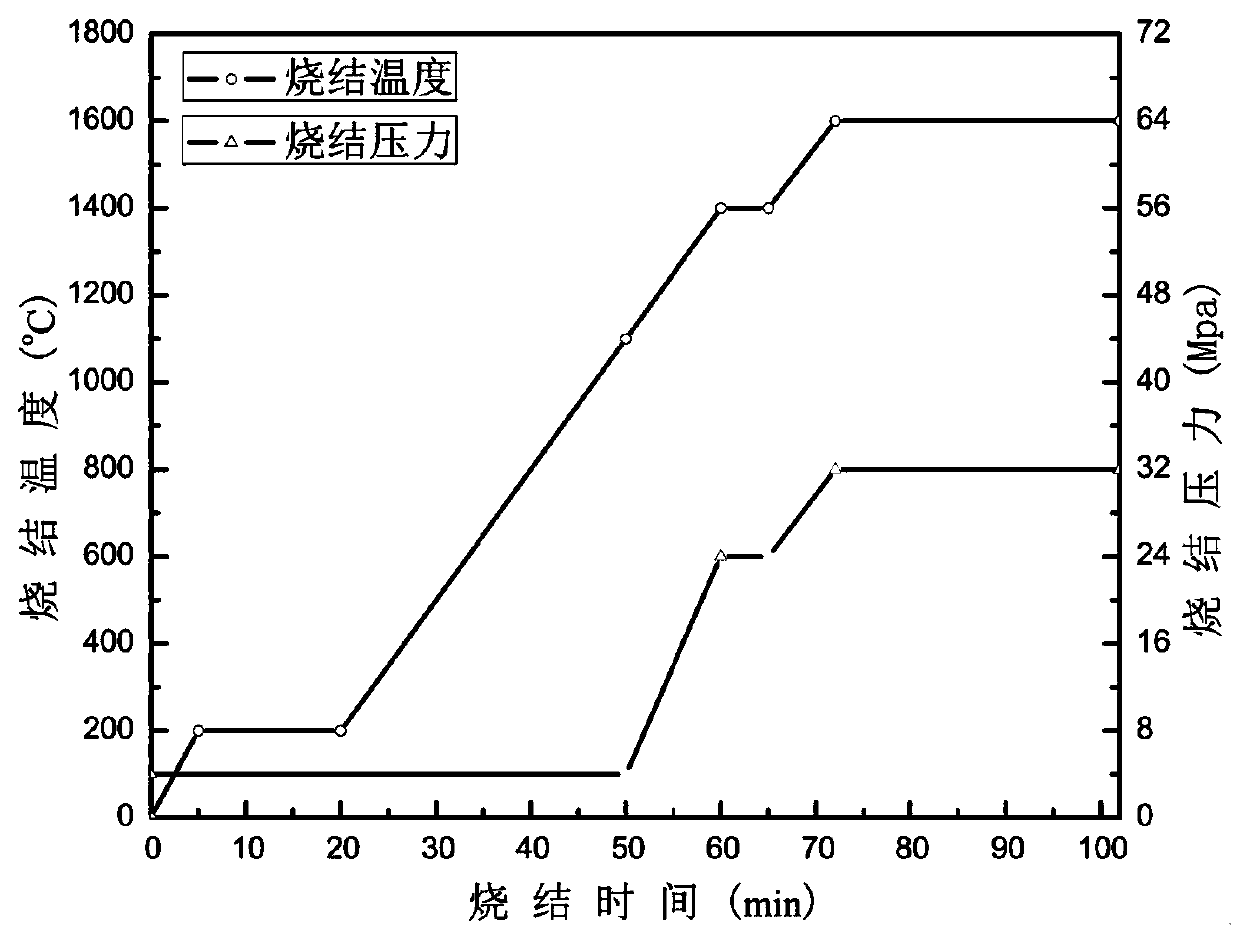

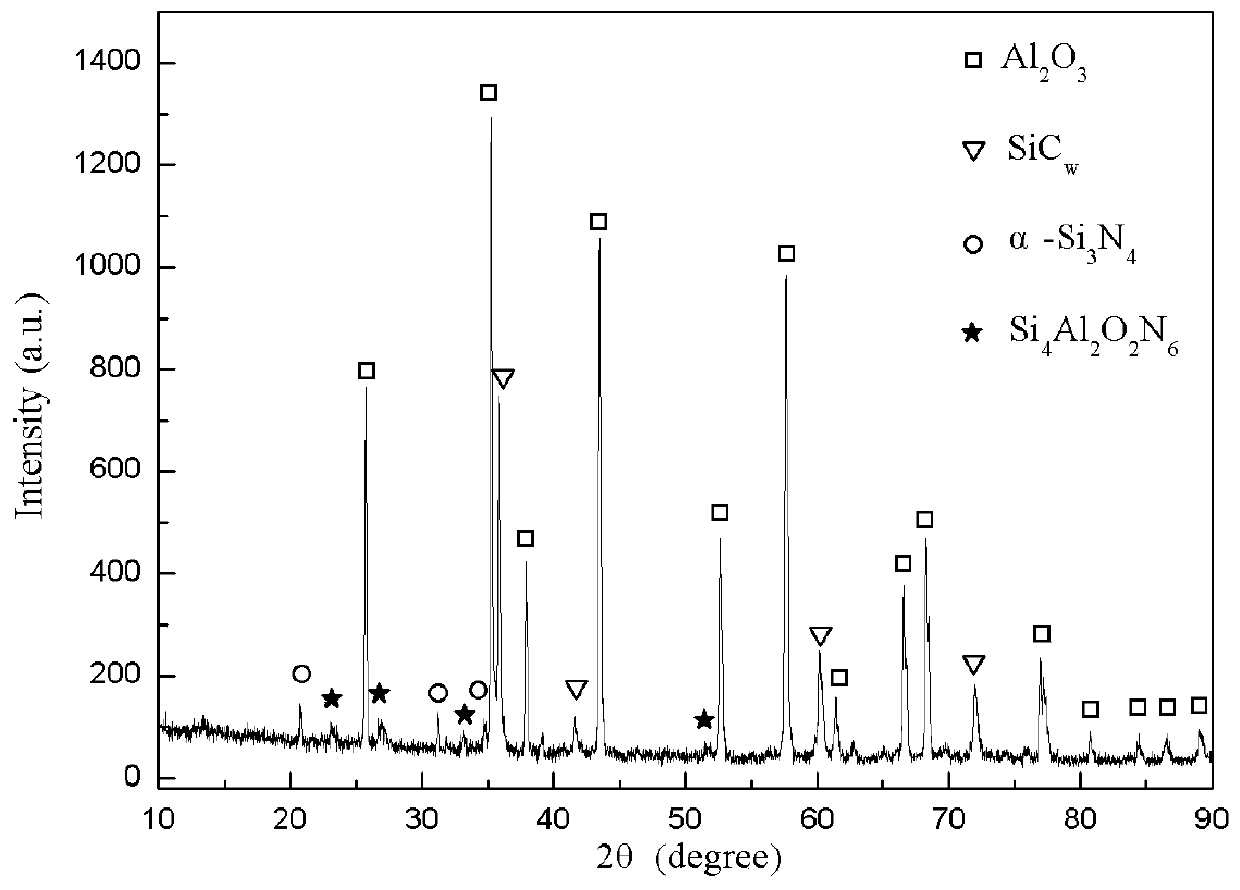

SiC whisker synergistic silicon nitride particle toughened alumina-based ceramic cutter material and preparation process thereof

ActiveCN110818395AImprove corrosion resistanceHigh processing compatibilityComposite ceramicCeramic knife

Owner:SHANDONG UNIV

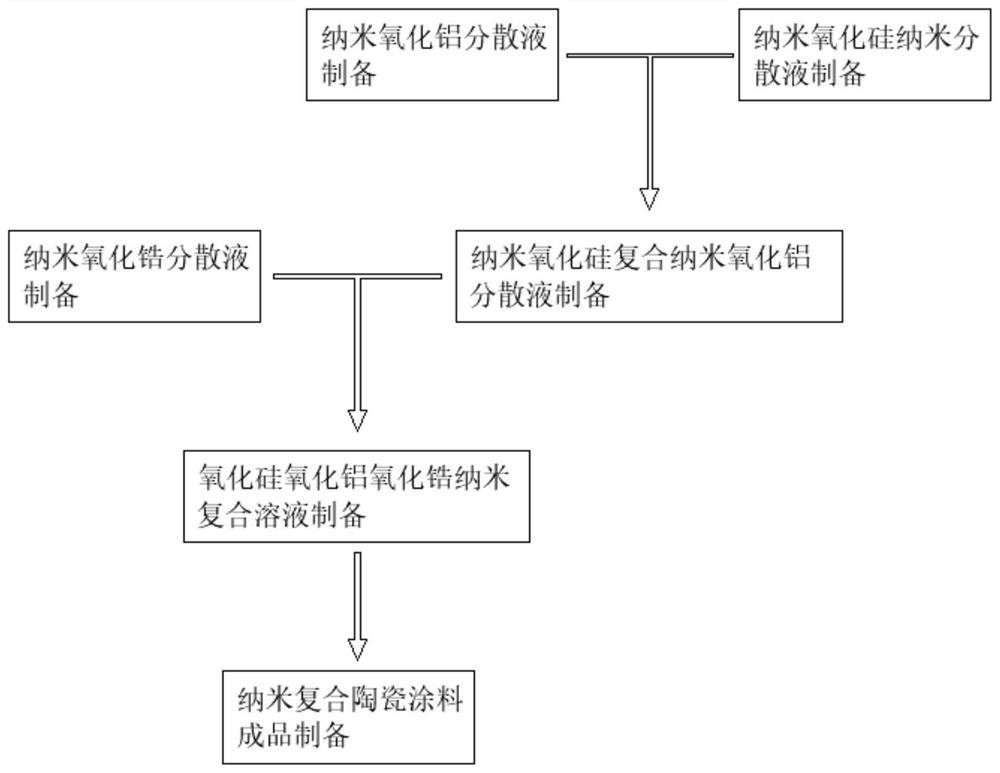

Transparent high-temperature-resistant anti-corrosion nano composite ceramic coating suitable for welding part

InactiveCN112898806AEasy to useGood value for moneyFireproof paintsAnti-corrosive paintsNano siliconComposite ceramic

Owner:薛国旺

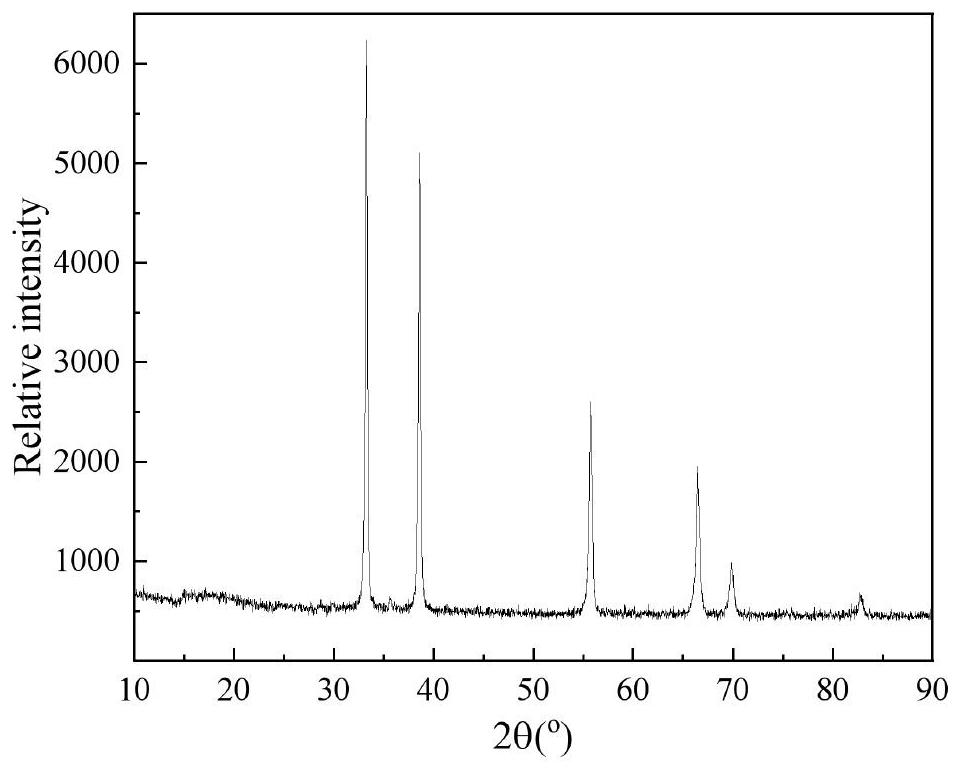

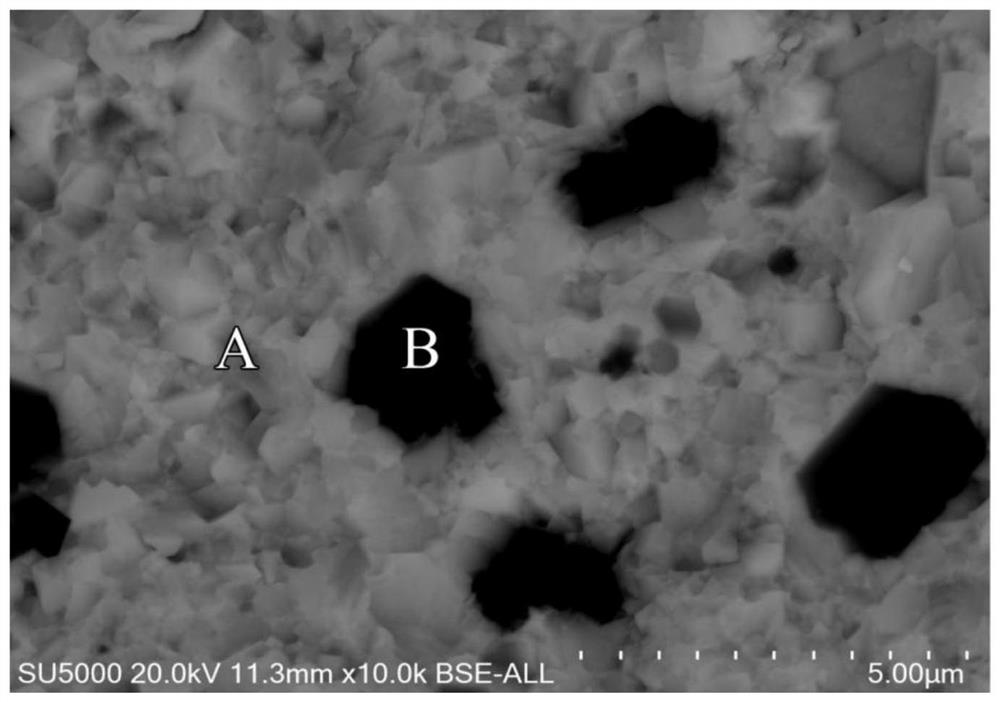

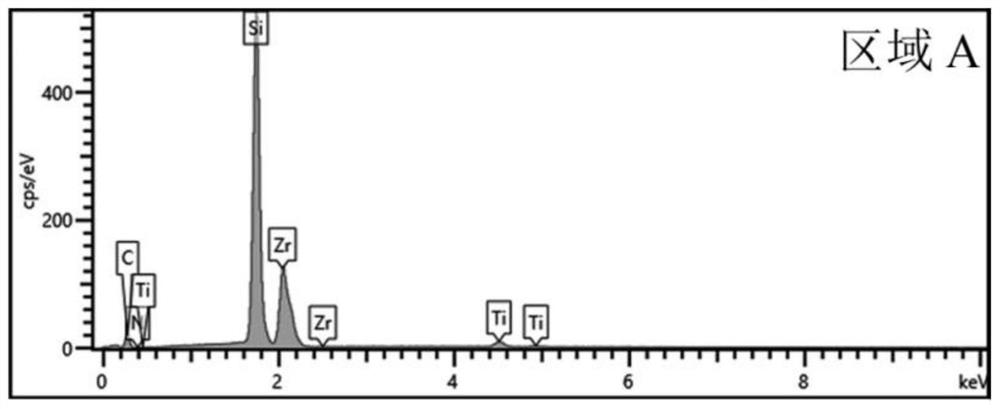

Method for preparing carbonitride-silicide solid solution composite ceramic at low temperature by reaction hot pressing sintering technology

PendingCN113999013AFacilitated DiffusionPromote interactionComposite ceramicCarbide

Owner:HARBIN UNIV OF SCI & TECH

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap