Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Pressure range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

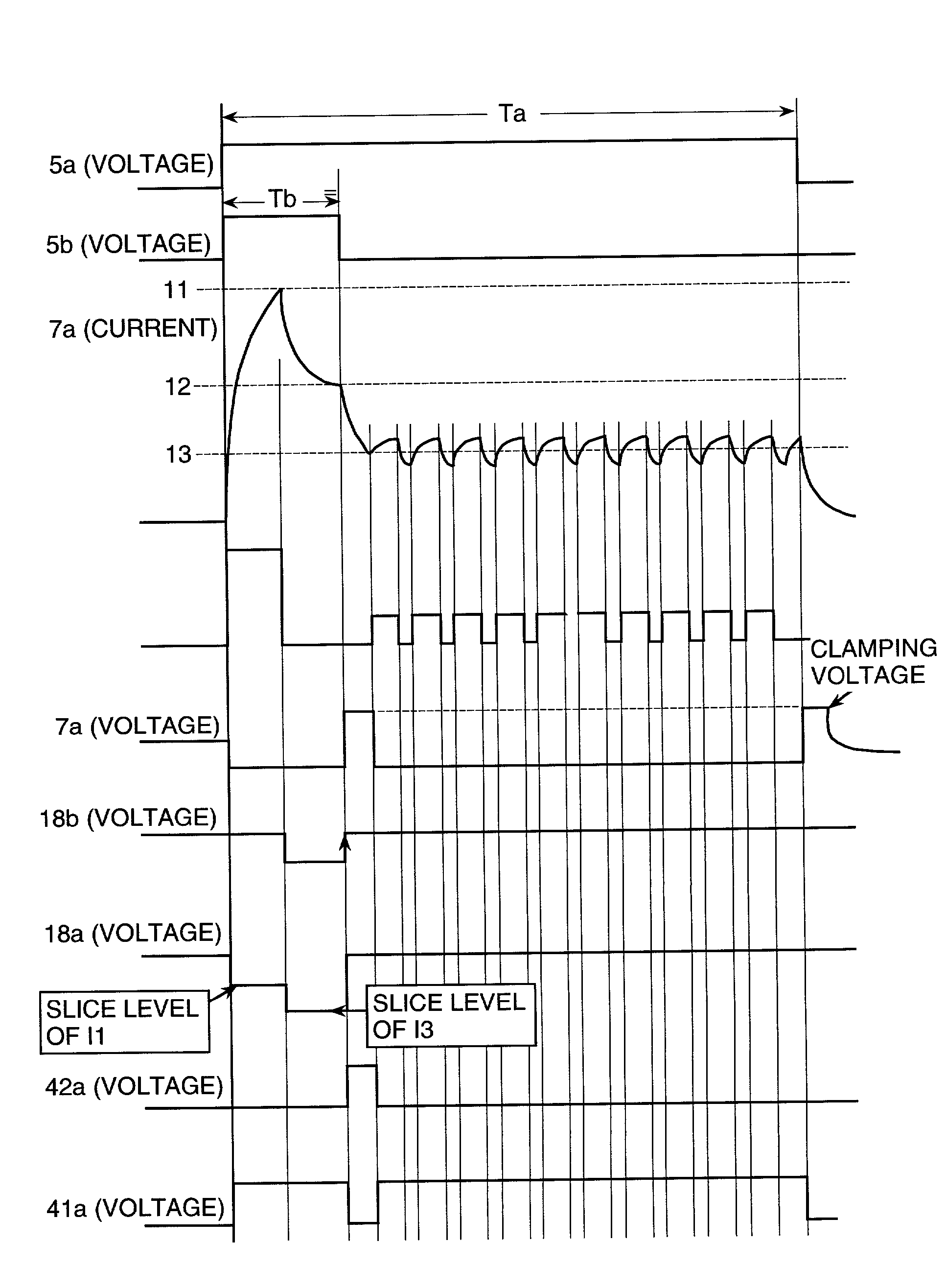

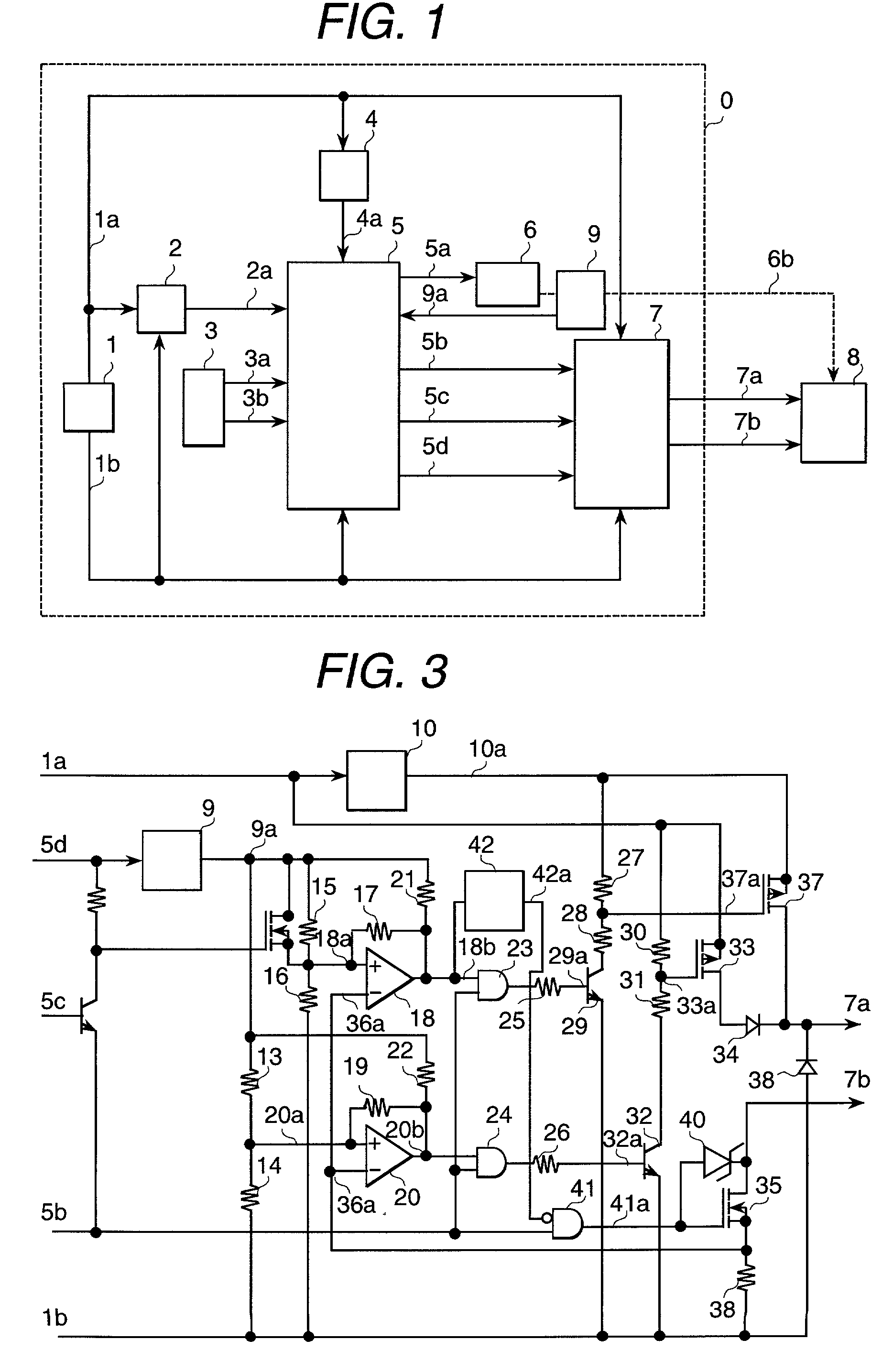

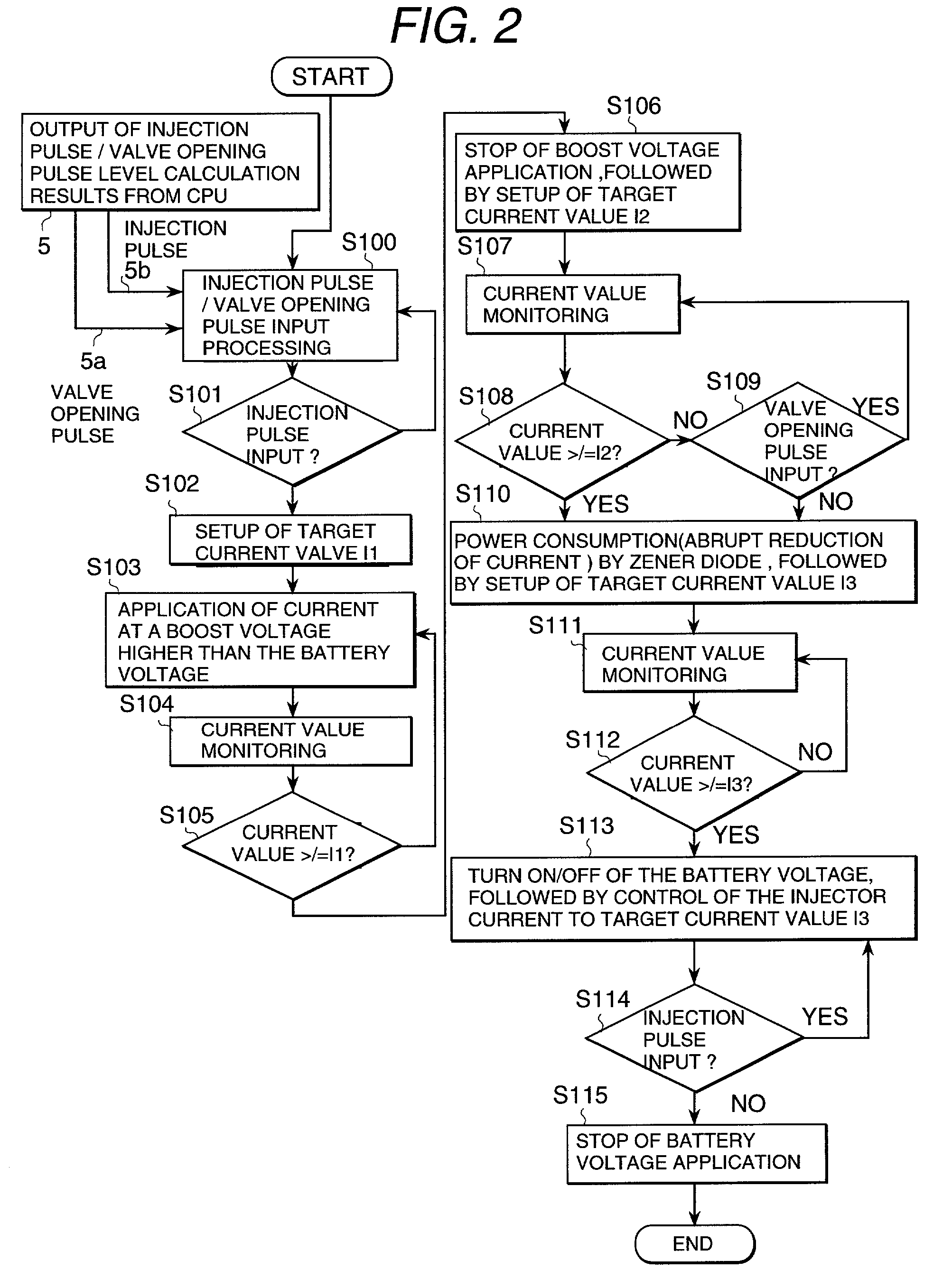

Injector driving control apparatus

Owner:HITACHI LTD

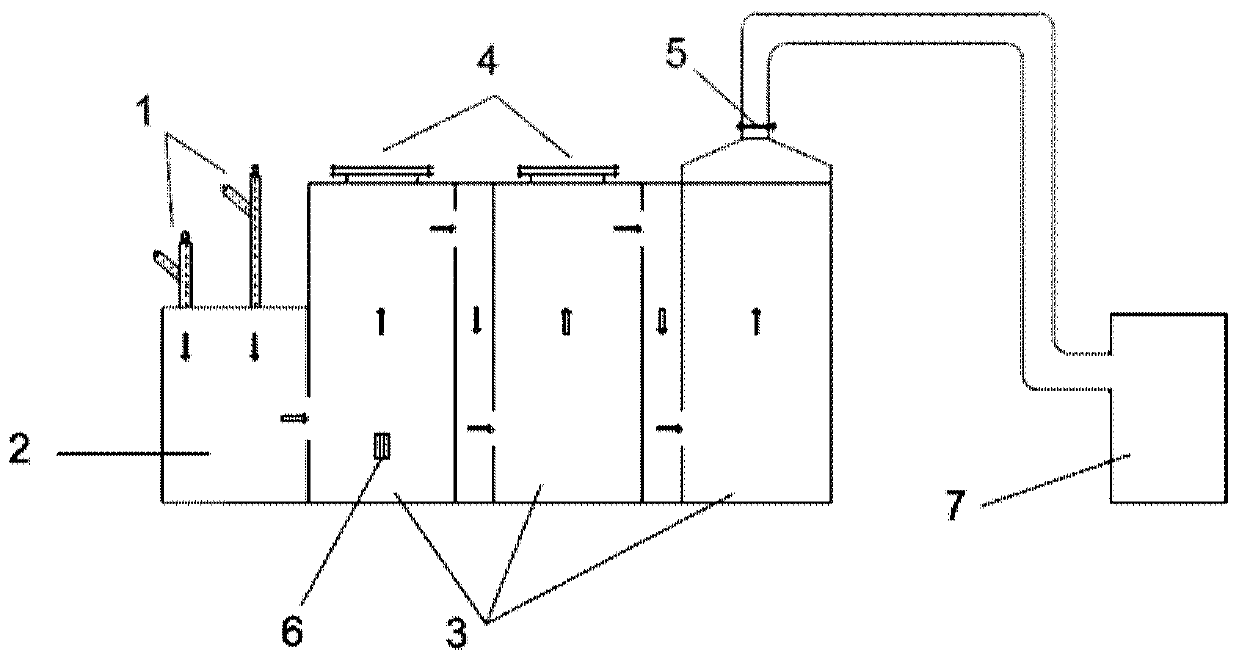

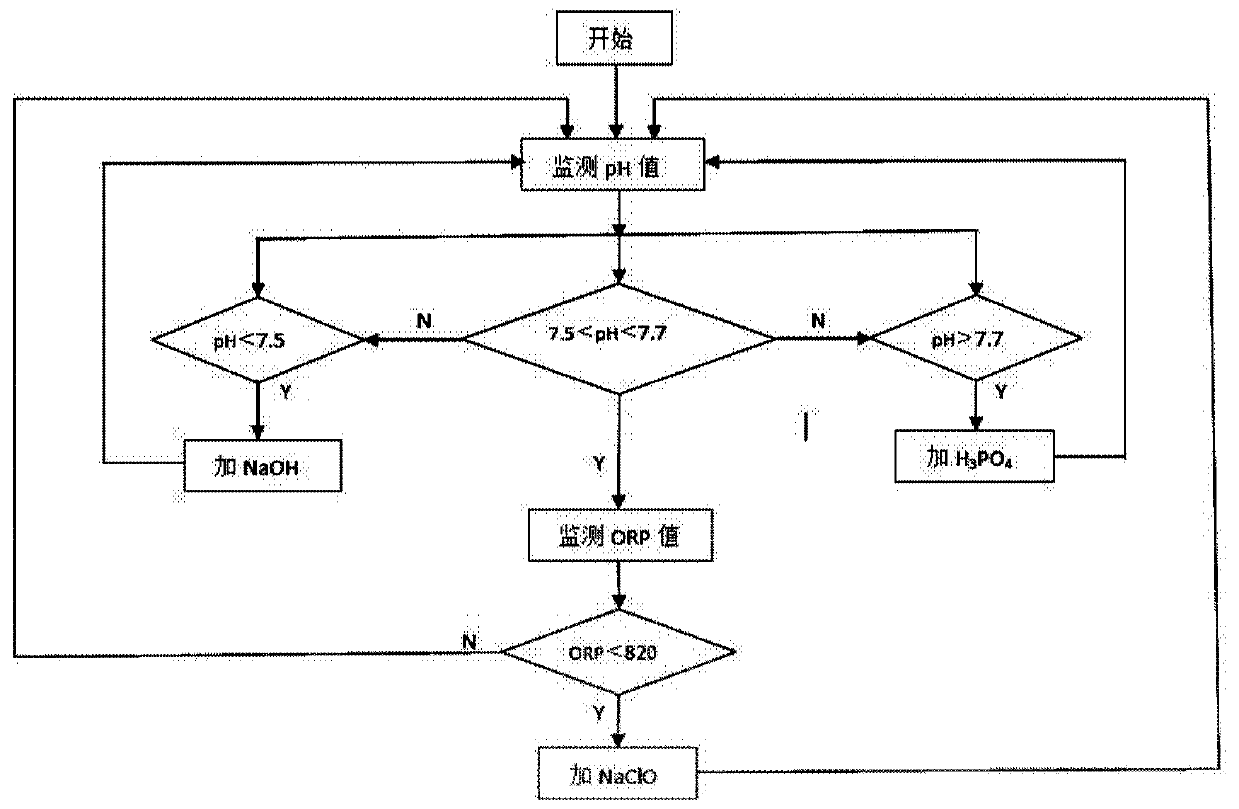

Exhaust gas treatment device of metal organic chemical vapor deposition apparatus and application of exhaust gas treatment device

PendingCN110339673APrevent leakageNo cloggingDispersed particle separationEngineeringChemical vapor deposition

Owner:DR TECH CO LTD YIXING JIANGSU

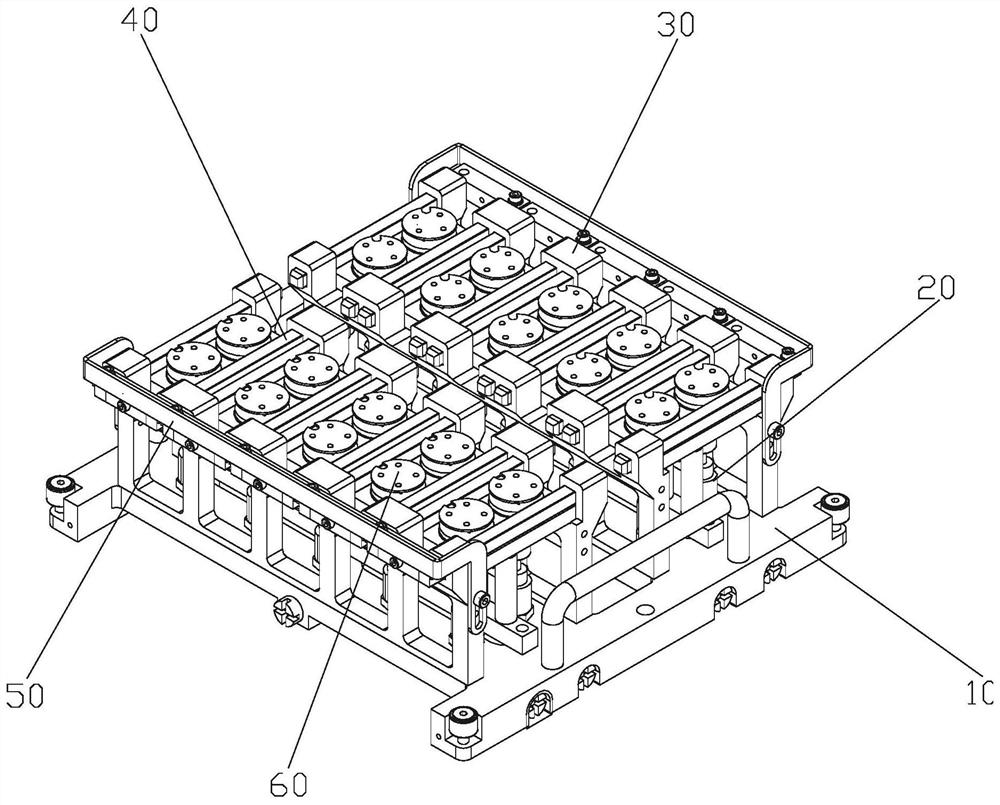

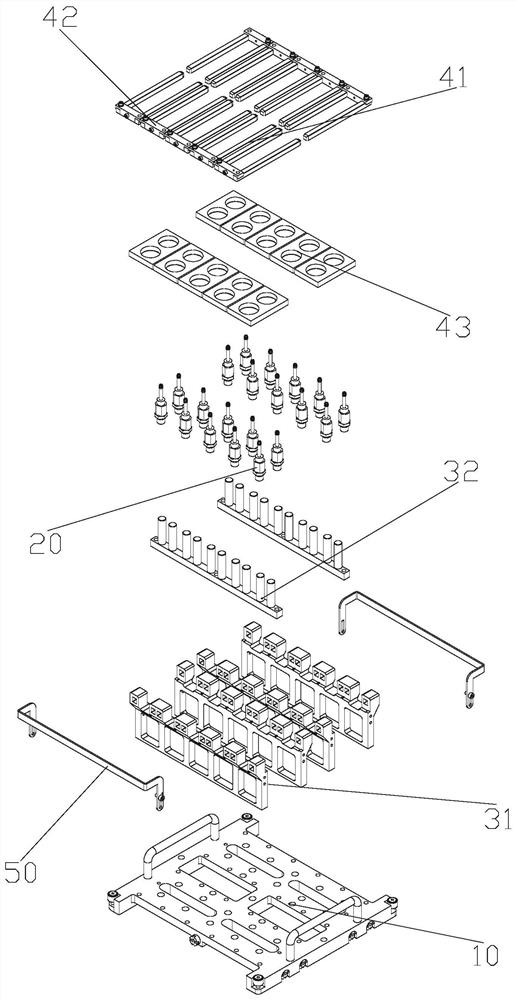

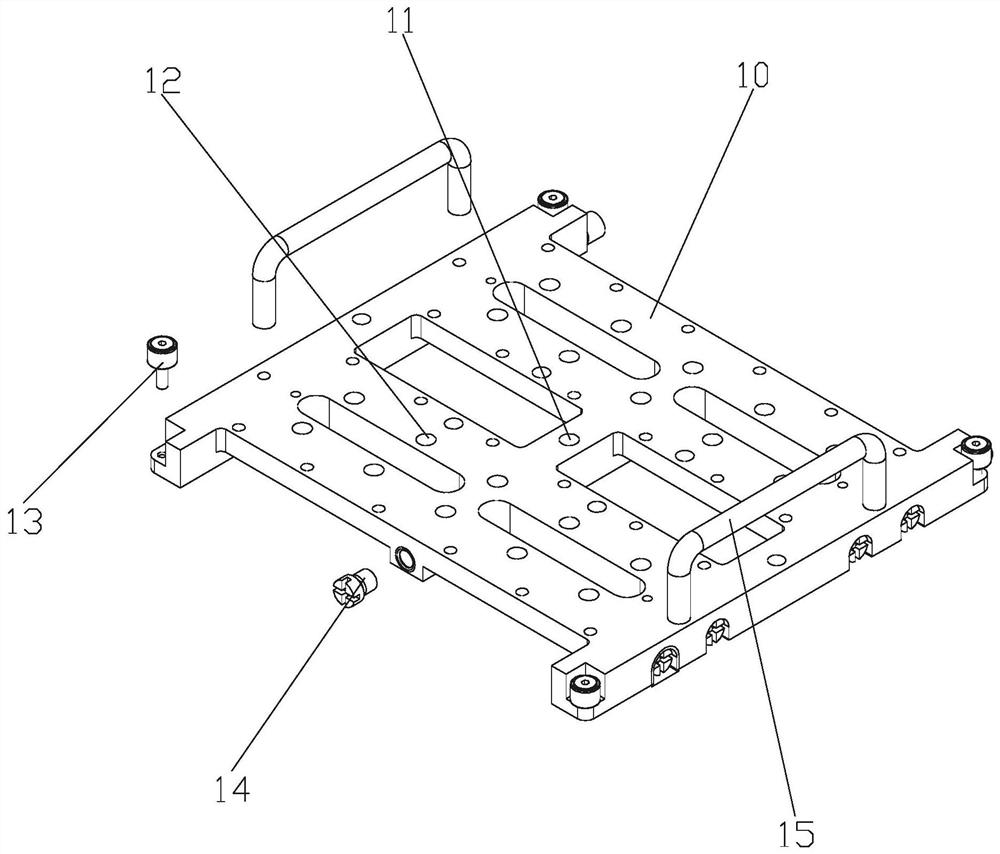

Tool for pressurization test of pressure transmitter

PendingCN113447200AEasy to operateReduce labor intensityFluid pressure measurementPhysicsPressure range

The invention relates to a tool for a pressurization test of a pressure transmitter. The tool comprises a bottom plate, a pressurization rod assembly, a supporting assembly and a limiting assembly. In the actual use process, the pressurization rod assembly and the supporting assembly are assembled in advance, when a pressurization test needs to be conducted on the pressure transmitter, a user aligns the bottom of the pressure transmitter to the upper portion of the pressurization rod assembly and vertically inserts the pressure transmitter into the pressurization rod assembly till the pressure transmitter makes contact with the supporting assembly, and then the limiting assembly is moved to the position above the pressure transmitter and is connected with the supporting assembly, then a pressure source is connected into the main pressurization hole, the pressure source flows into the branch pressurization holes and is guided into the pressure transmitter through the pressurization rod assembly for pressure testing, and therefore threaded fastening and sealing are not needed, operation is easy, labor intensity is low, the tool can be quickly assembled and disassembled, is large in adaptive pressure range, and can be better used for automatic testing of a production line.

Owner:北京清大天达光电科技股份有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap