Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Production planning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production planning is the planning of production and manufacturing modules in a company or industry. It utilizes the resource allocation of activities of employees, materials and production capacity, in order to serve different customers.

Production scheduling system and method using genetic algorithm based on elite solution pool

InactiveCN101271543AFast convergenceImprove the efficiency of blind random operationsGenetic modelsResourcesOrder formGenetic algorithm

The invention provides a production scheduling system and a method thereof. The system consists of a terminal of a production planning department, a server and a database for storing historical data. The terminal of the production planning department acquires and finishes data real-timely from the connected information terminals through the server. An order is coded through a genetic algorithm basing on an elite hydrolytic tank. Then, genetic operations such as selective transposition, etc., which are executed and evaluated and optimized layer by layer are implemented to generate an optimal production schedule. Finally, a production scheduling proposal is transferred to a production workshop through the server and feedback data on a processing field are real-timely received for the proposal regulation. The hardware environment of the system can be easily realized, the method of the system combines with a heuristic rule and the genetic algorithm, thus the system of the invention improves the solving result and the operation speed during the solving of the scheduling proposal under the condition that a large number of orders, a multilayer structure and the complex process are provided. The production scheduling system and the method of the invention has the advantages of wide application range, strong expandable type, fast operation speed, good optimal performance, etc.

Owner:YONGKAI SOFTWARE TECH (SHANGHAI) CO LTD

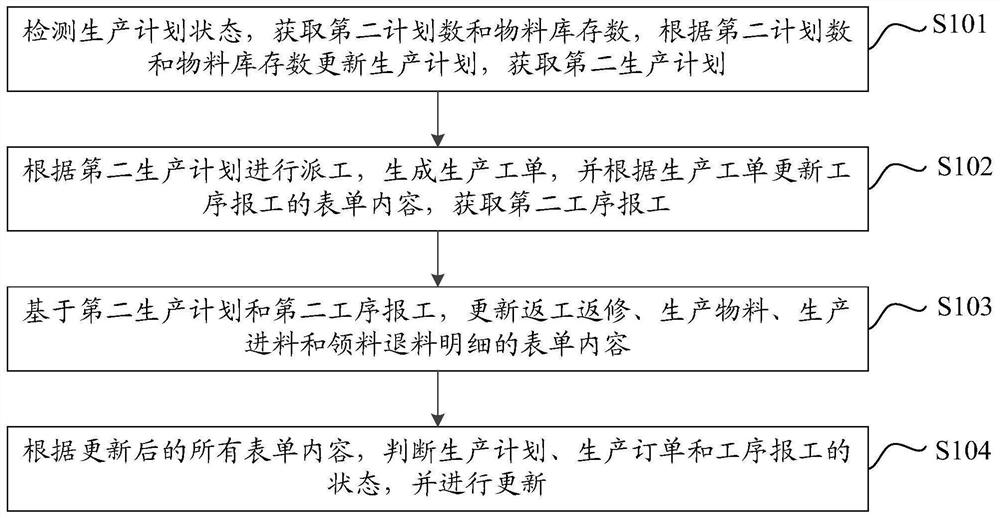

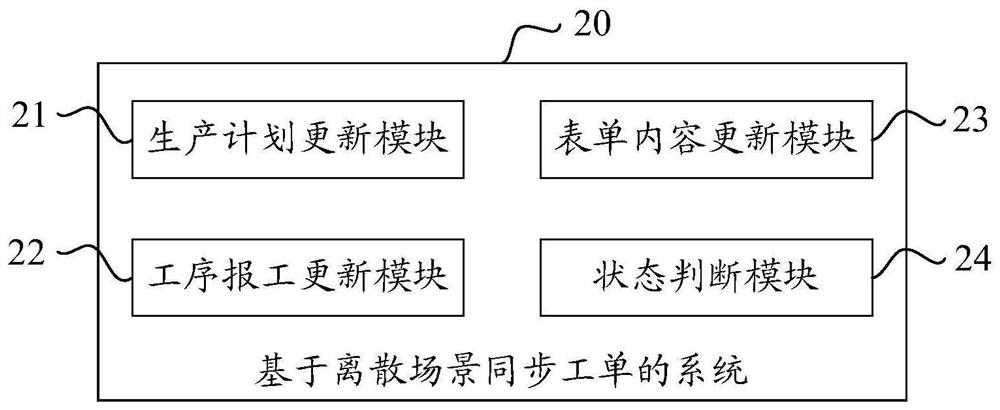

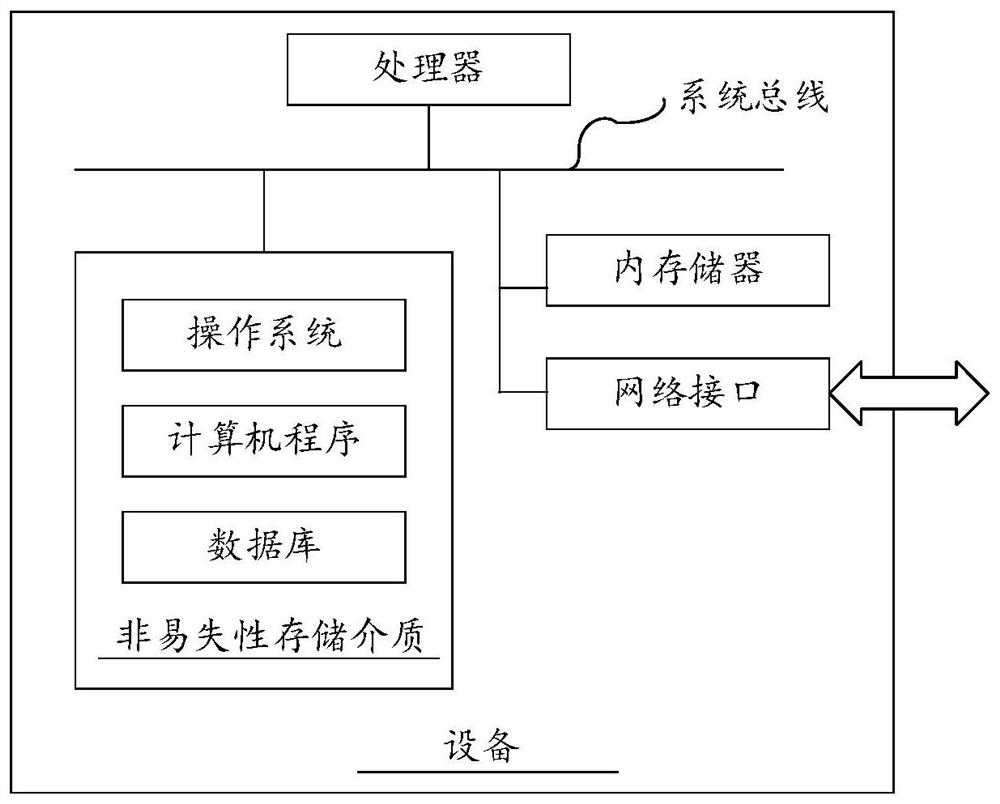

Work order synchronization method and system based on discrete scene, equipment and storage medium

PendingCN113807821ADatabase distribution/replicationTechnology managementProduction planningManufacturing engineering

Owner:重庆允成互联网科技有限公司

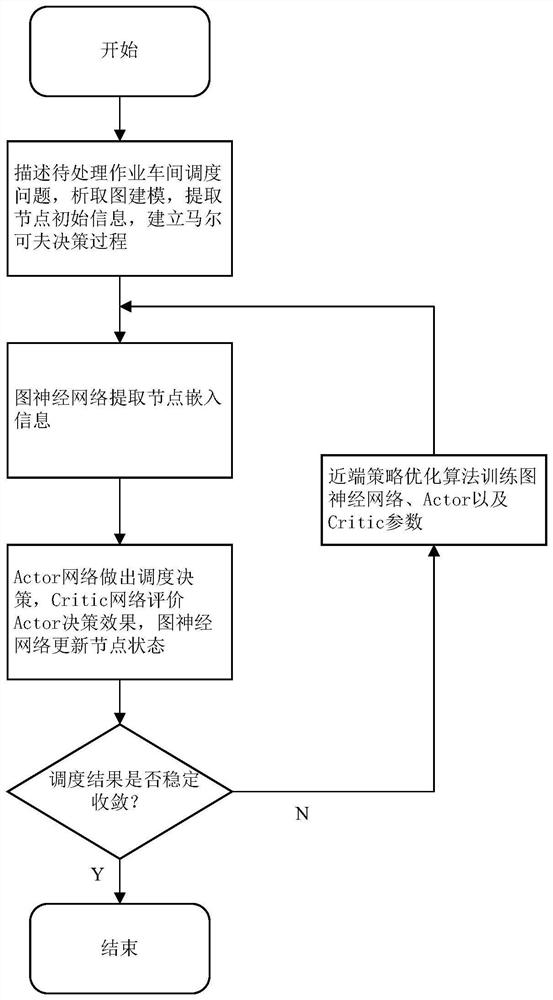

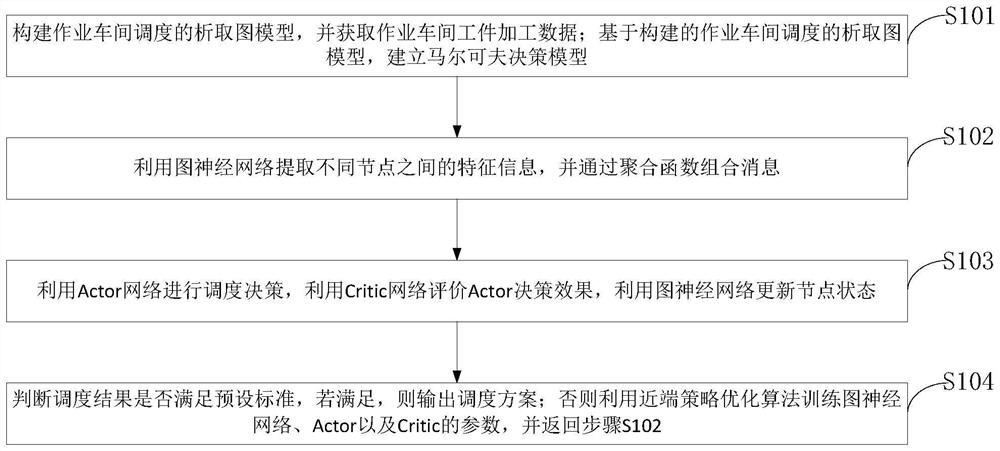

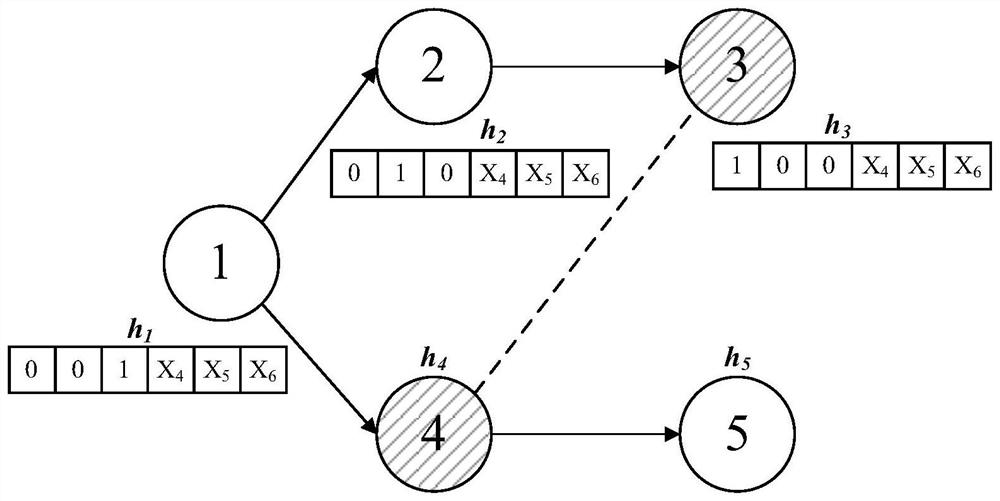

Job-shop scheduling method based on graph neural network

PendingCN114757512ACreativeScheduling does not affectMathematical modelsNeural architecturesGraph neural networksArtificial intelligence

Owner:WUHAN UNIV OF TECH

Intelligent MES platform software operation method

PendingCN112650508AImprove work efficiencyData authenticityDigital data authenticationResourcesBusiness enterpriseBusiness process

The invention discloses an intelligent MES platform software operation method, which comprises the steps of obtaining a software installation program package on a computer; obtaining a software installation instruction; after software installation is completed, obtaining a software running request; logging in an account number, wherein the account number comprises a management end account number and a basic personnel account number; enabling the basic personnel to upload the working data to the software through the basic personnel account, and enabling the management terminal to check, modify and annotate the working data in the software through the management terminal account; according to the method, the working efficiency is effectively improved, various data in an enterprise is relatively real, and available resources are integrated: a plan layer and an operation layer of the enterprise are connected, and an information island is integrated; the production process is optimized: carding and optimizing the current production business process through project implementation; and the management means is improved: comprehensively integrating activities such as production planning, schedule arrangement, material tracking, process control, process monitoring, quality management, equipment maintenance and the like in the manufacturing process.

Owner:HAITONG ANHENG TECH CO LTD

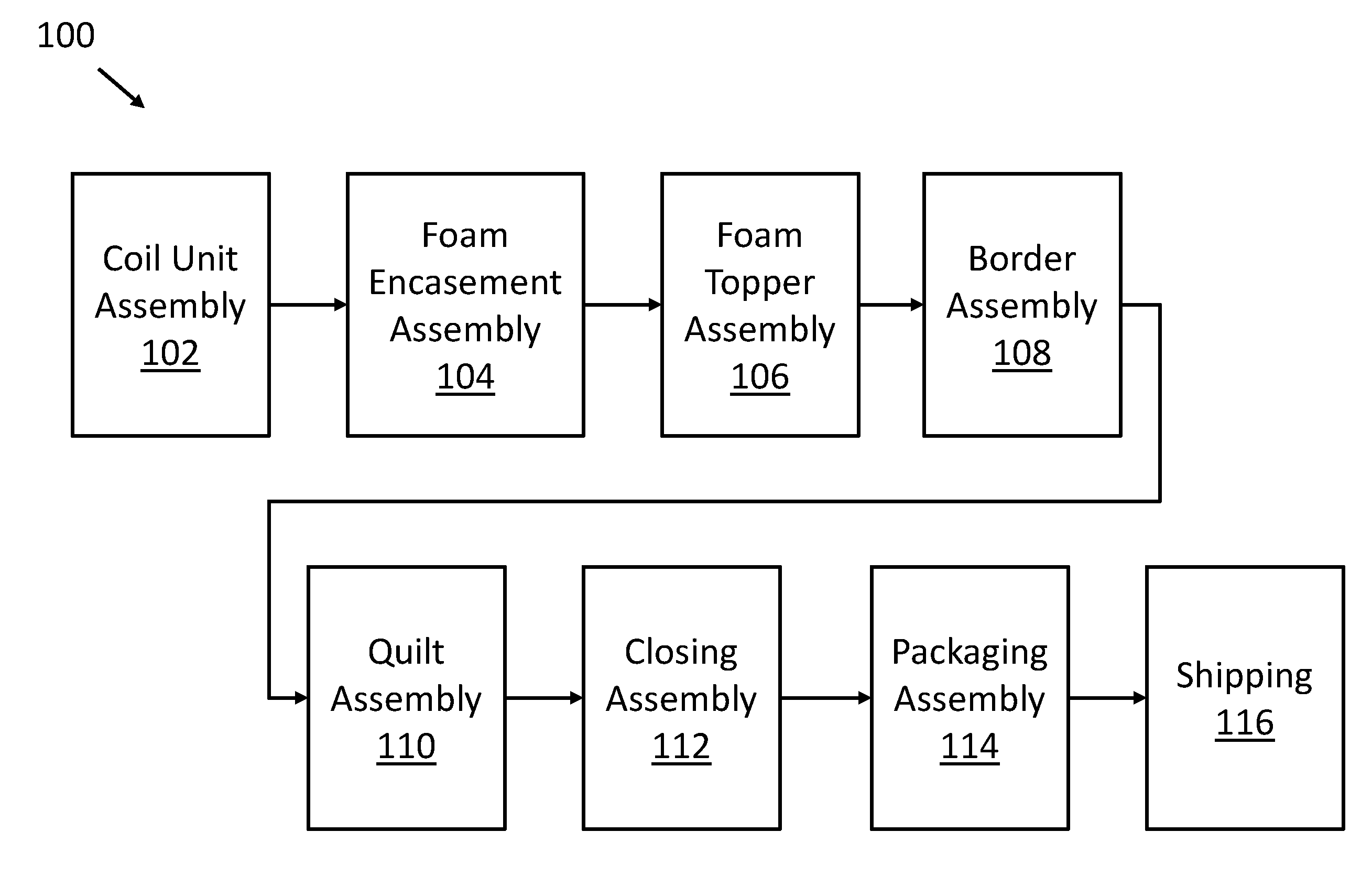

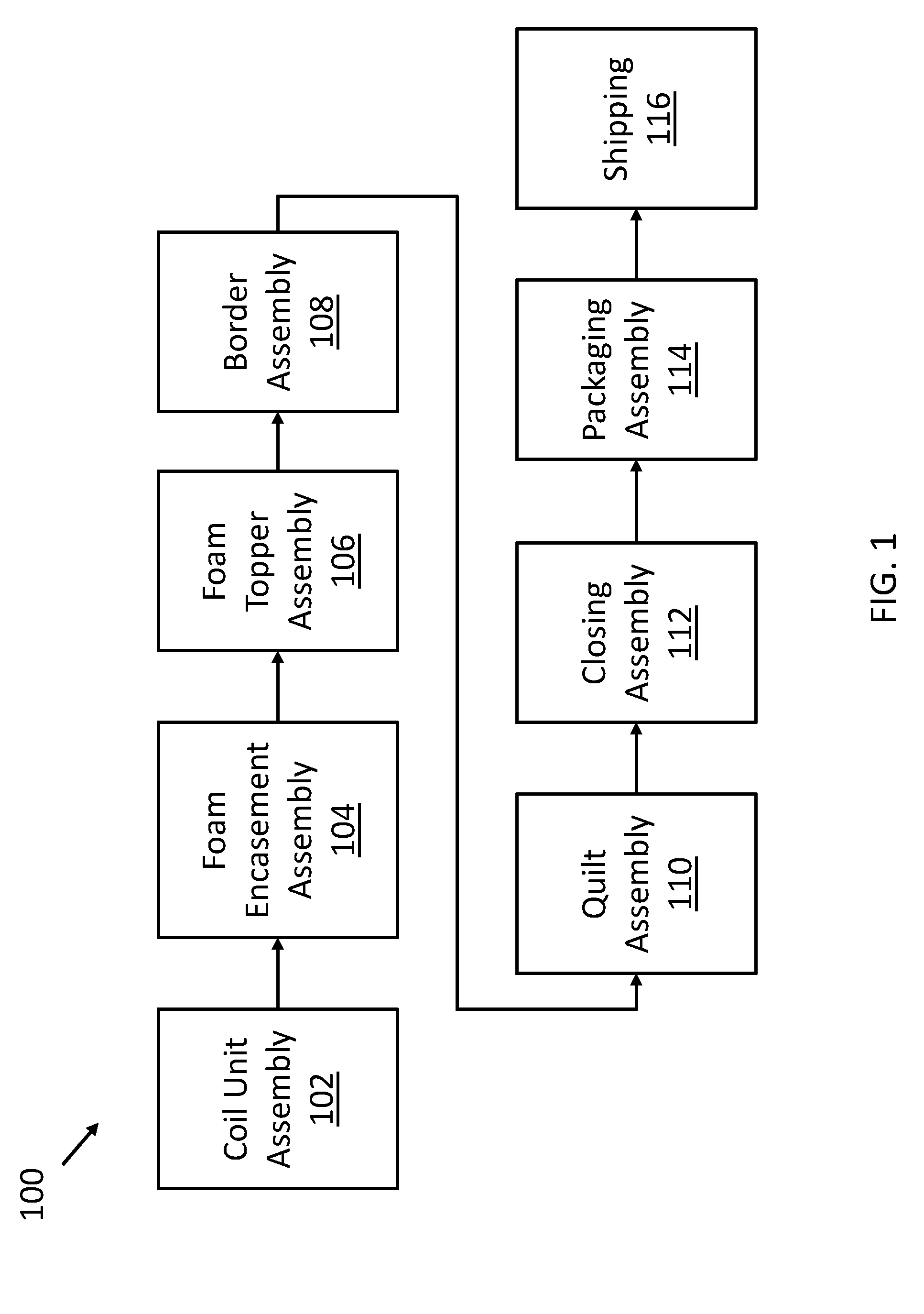

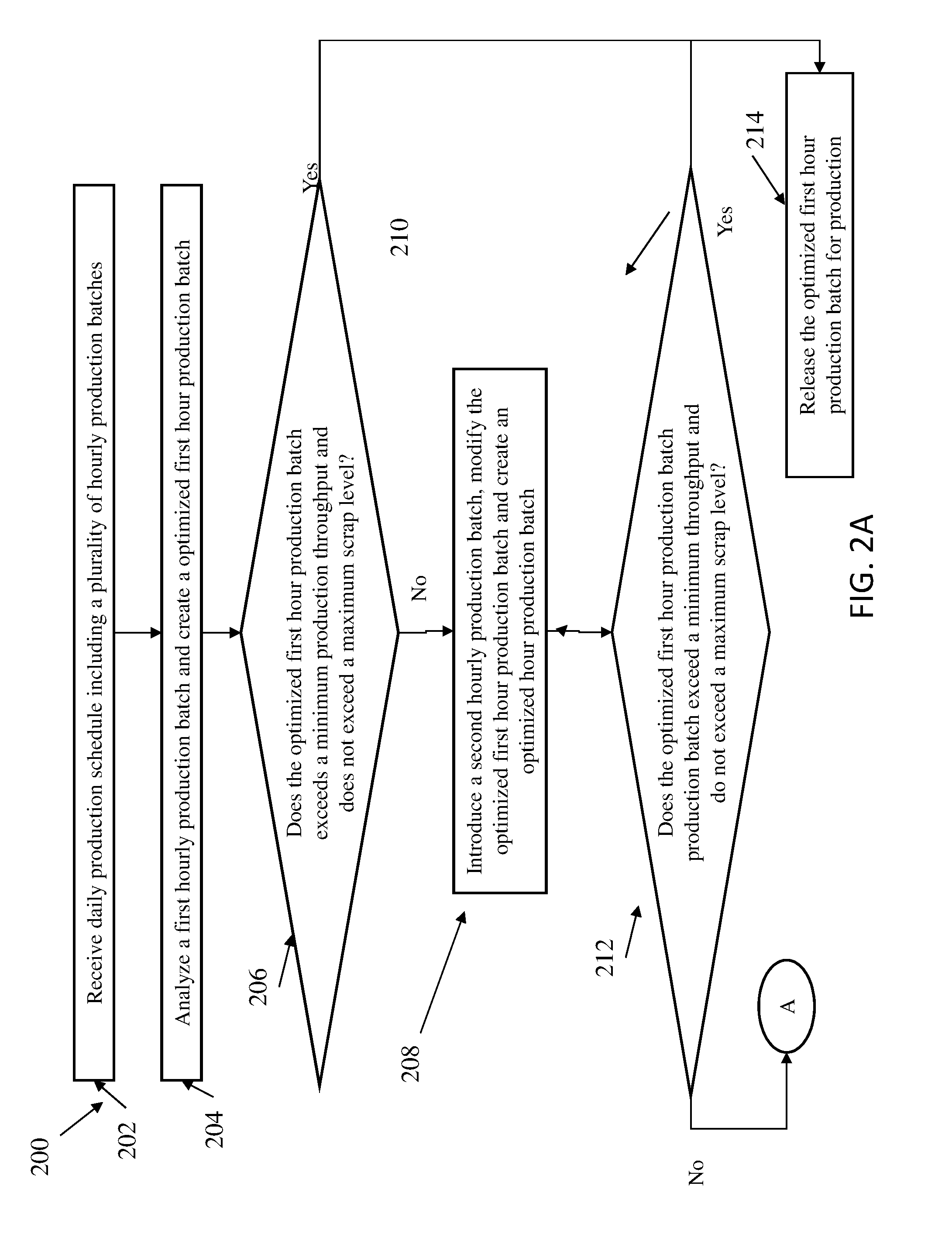

Scheduling process for automated mattress manufacturing

ActiveUS20160216707A1Maximize throughputReduce down timeResourcesTotal factory controlProgram planningCustomer order

Owner:DREAMWELL

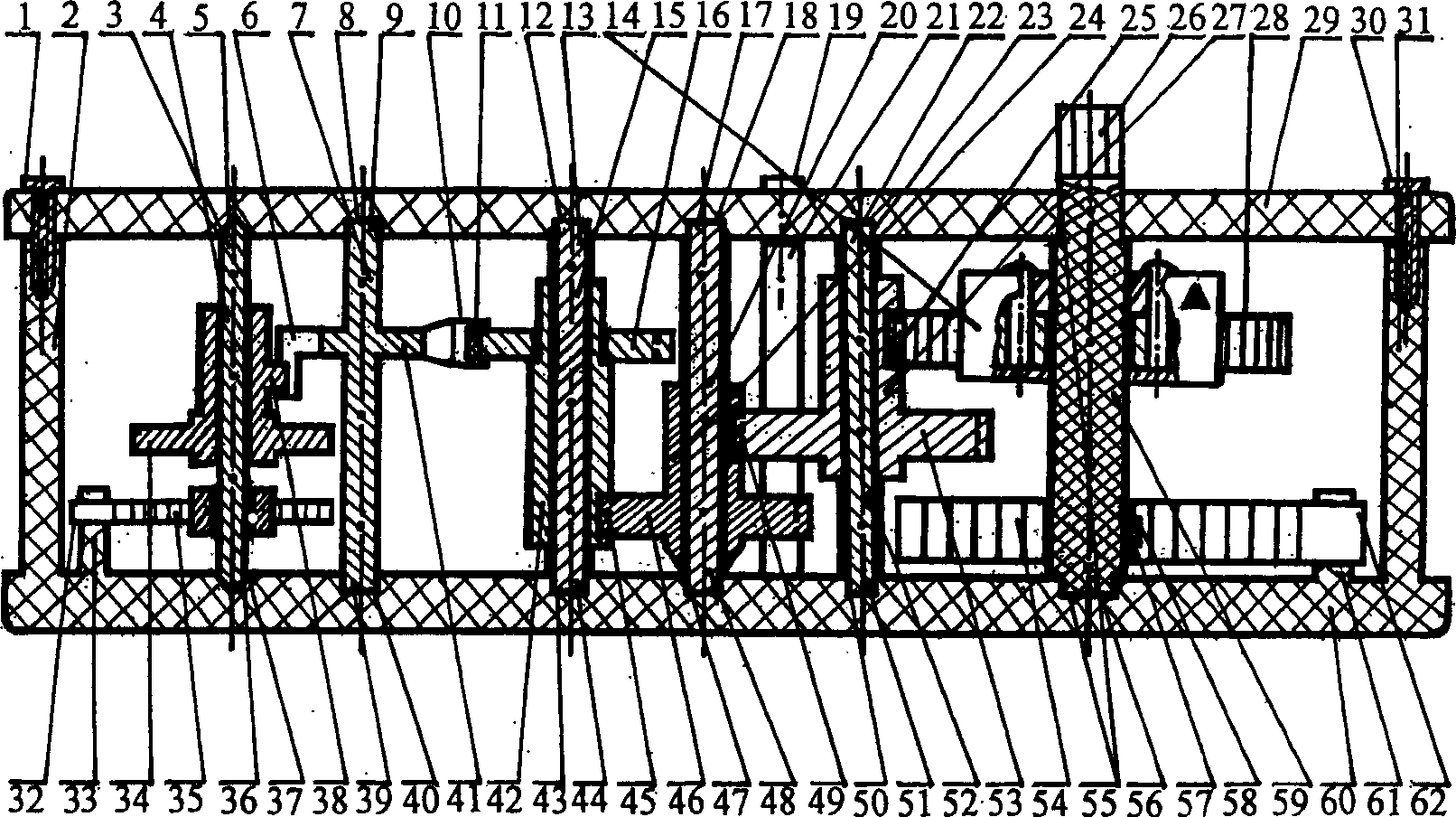

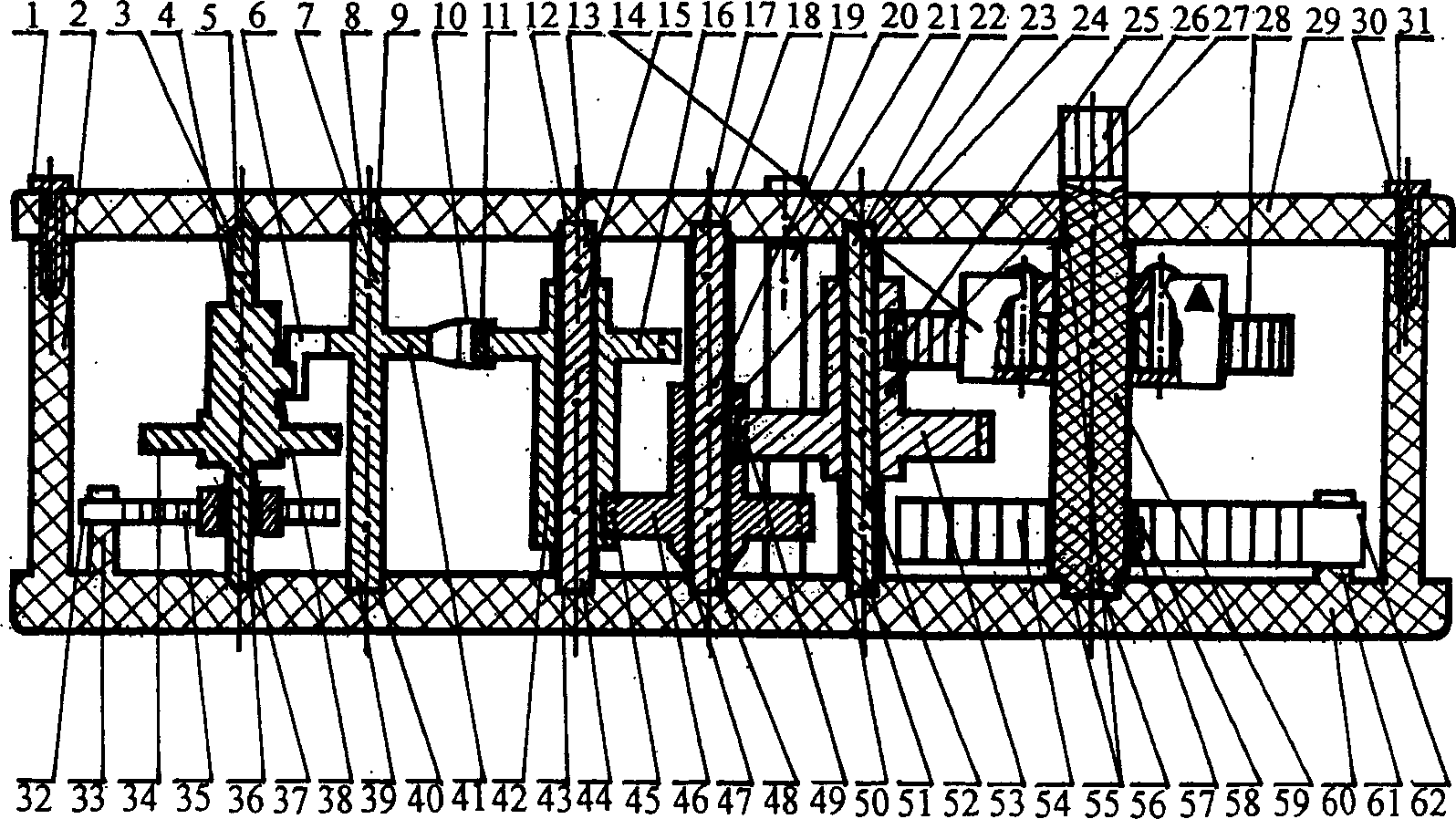

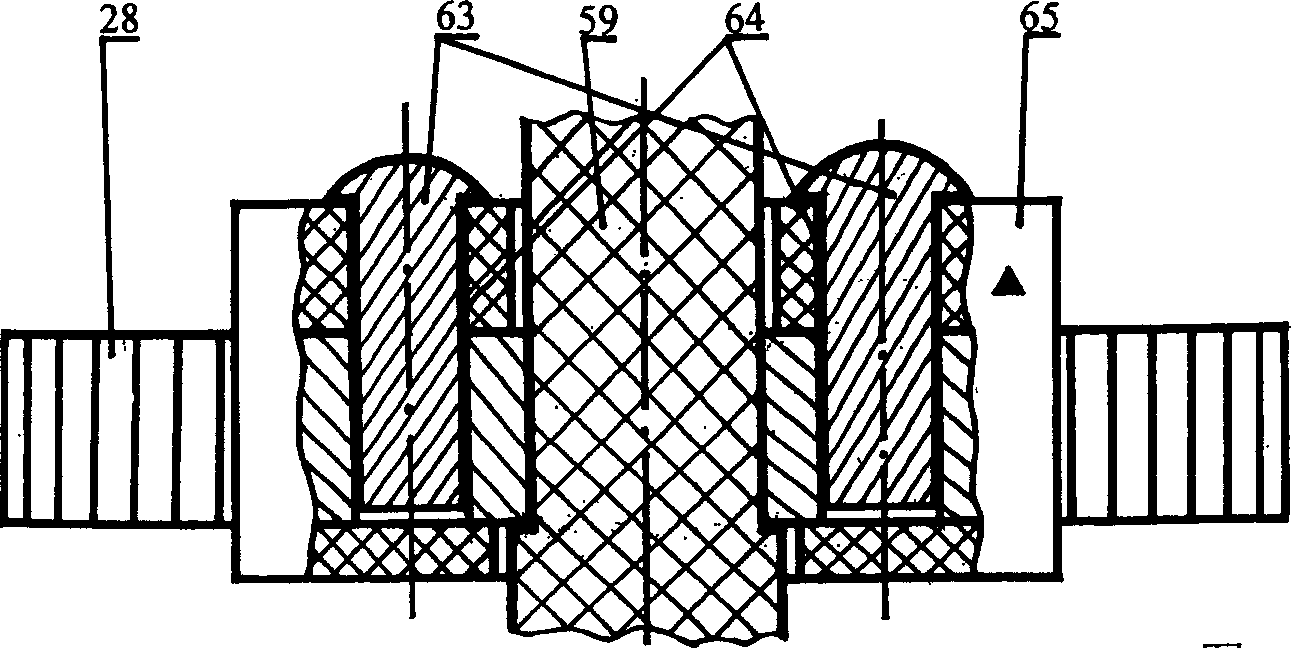

Mechanical timer travel-time system of gear-cover tooth-change series

InactiveCN1776871ATime-programme switchesTime interval measurement with driving mechanismProduction planningEngineering

Owner:徐国林

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap