Reaping machine grading sieve

A technology for cleaning sieves and harvesters, which is applied to agricultural machinery and implements, threshing equipment, applications, etc., can solve the problems of harvesting adaptability limitations, affecting cleaning effects, and reducing cleaning quality, etc., to improve cleaning The effect of improving the selection quality and cleaning effect and improving the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

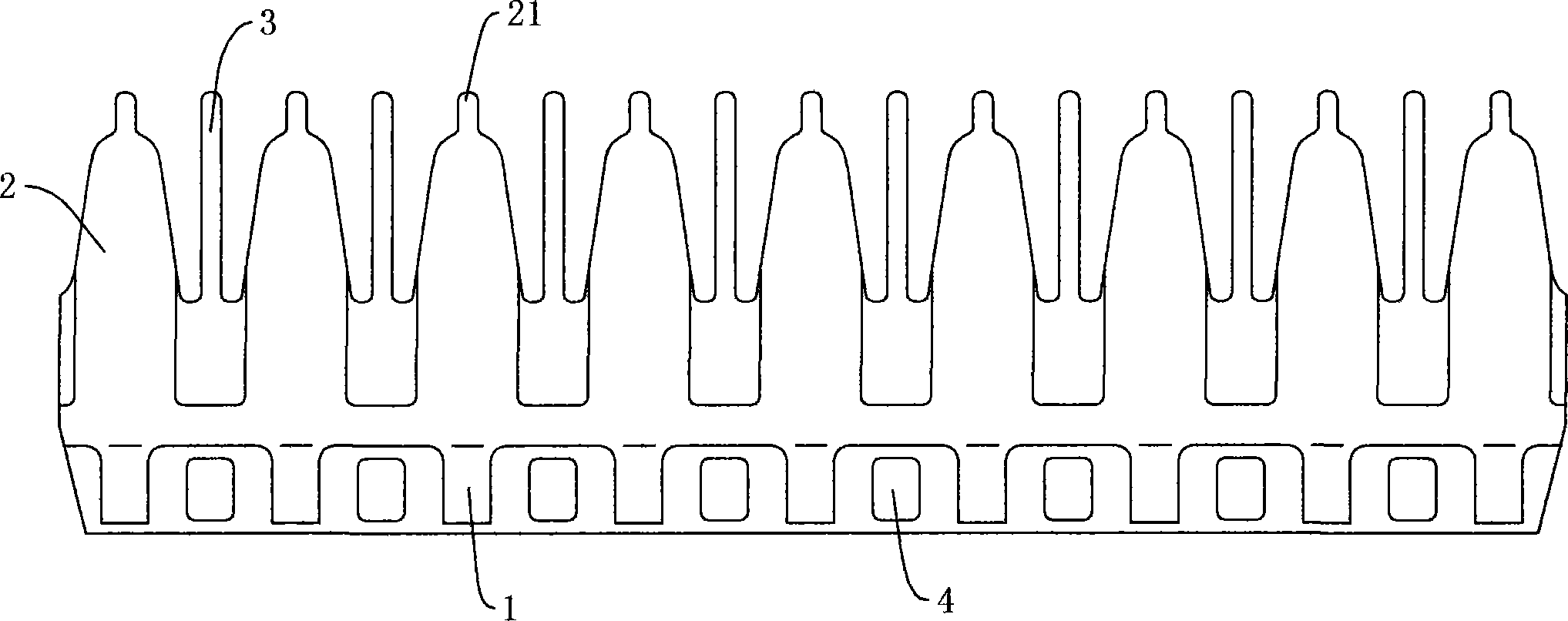

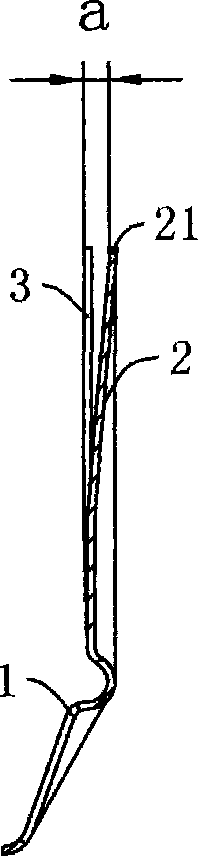

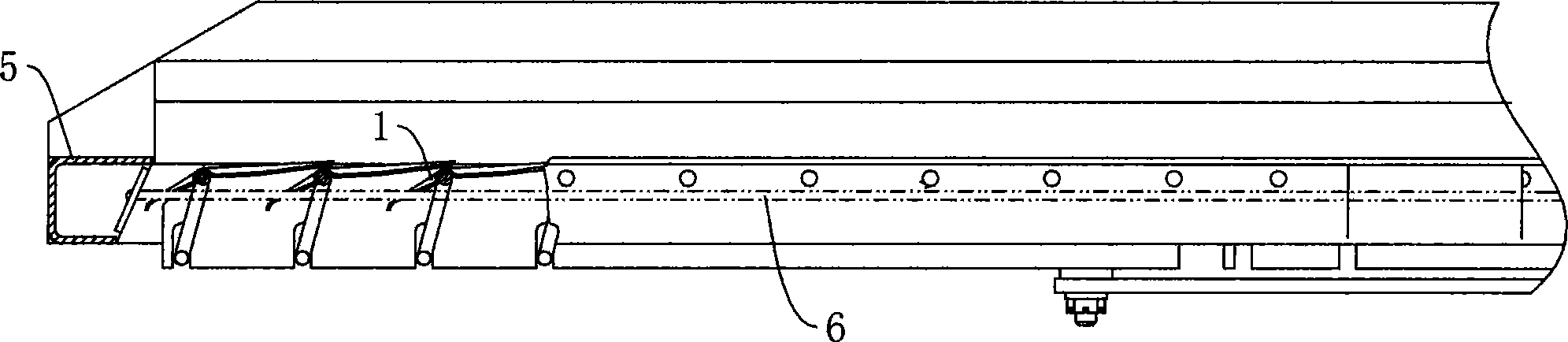

[0013] like Figure 4 and image 3 As shown, the harvester cleaning screen includes a number of fish scale screen sieve plates 1 arranged in sequence on the screen frame 5, and a number of fish scale screen plates 2 arranged in sequence at the front of the sieve plate 1, which are controlled by the fish scale screen adjustment device. The opening of each fish scale sieve plate 1 is suitable for different cleaning operation environments; a number of perforation holes 4 are arranged in sequence at the rear of each sieve plate 1, and a number of perforation strips 6 pass through the corresponding perforations on each sieve plate 1 in sequence. The strip holes 4 and the sieve plates 1 are strung together. In actual use, steel wire strips can be used for the thread strips 6 to improve the service life. By arranging the wire piercings in the piercing holes in sequence, the larger gap between the sieve plate and the sieve plate after adjustment and opening is divided to form several sm

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap